Method for producing n-hexane containing heptane raw material

A production method and technology of n-hexane, which are applied in chemical instruments and methods, purification/separation of hydrocarbons, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that it is difficult to obtain high-purity isohexane and n-hexane products. , increase the processing load of n-hexane raw materials, it is difficult to meet the requirements of process indicators, etc., to achieve good stability and regeneration performance, long-term operation, and flexible adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

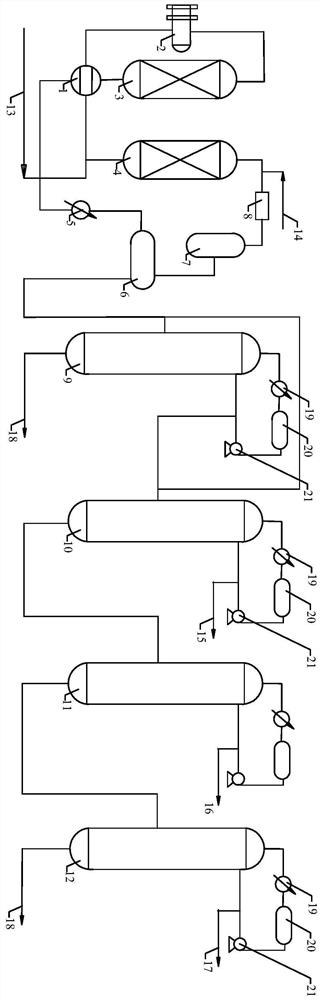

Image

Examples

Embodiment 1

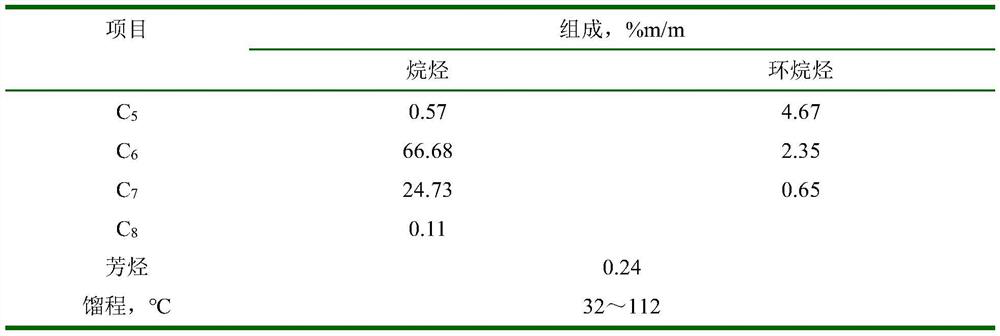

[0024] The properties of raw materials are shown in Table 1.

[0025] Table 1 Raw material properties 1

[0026]

[0027] A kind of n-hexane production method that contains heptane raw material, it comprises the following steps:

[0028] Step 1. After the raw material is mixed with hydrogen and exchanged heat with the reaction product, the temperature is 142°C. After being heated by a heater to 172°C, it enters the reactor to contact with the catalyst, and the hydrofining reaction is carried out under the action of the hydrofining catalyst. The catalyst is Ni-based catalyst, the appearance is spherical, and the specific surface area of the catalyst is 50-90m 2 / g, pore volume: 0.15~0.3ml / g, bulk specific gravity: 0.6±0.02g / ml, radial compressive strength: 24~38N / grain.

[0029] Step 2, the reaction product enters the deheptanizer for pre-fractionation after gas-liquid separation in the low-pressure separator, and most of the heptane in the reaction product is separated,...

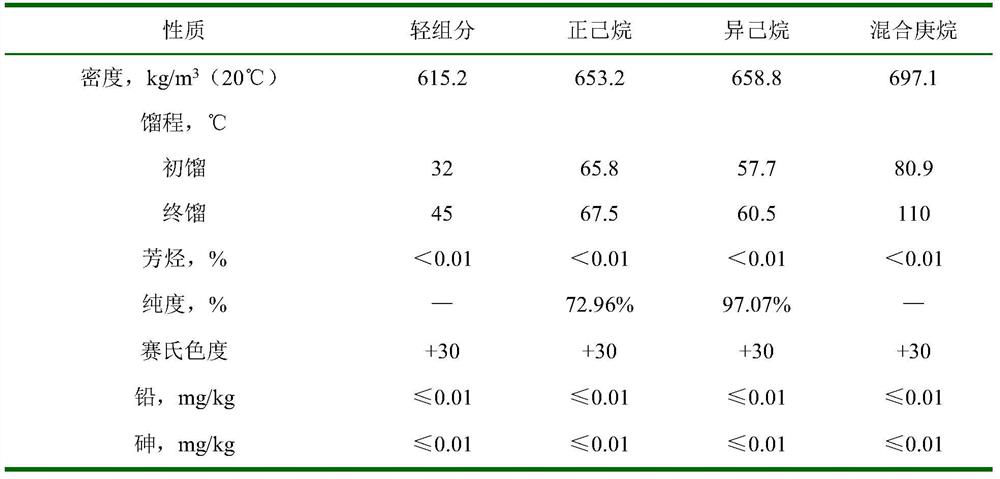

Embodiment 2

[0038] See Table 4 for raw materials.

[0039] Table 4 raw material crude hexane properties 2

[0040]

[0041] A kind of n-hexane production method that contains heptane raw material, it comprises the following steps:

[0042] Step 1. After mixing the raw material with hydrogen and exchanging heat with the reaction product, the temperature is 136°C, heated to 178°C by the heater, entering the reactor to contact with the catalyst, and the hydrofining reaction is carried out under the action of the hydrofining catalyst. The catalyst is Ni-based catalyst, the appearance is spherical, and the specific surface area of the catalyst is 50-90m 2 / g, pore volume: 0.15~0.3ml / g, bulk specific gravity: 0.6±0.02g / ml, radial compressive strength: 24~38N / grain. .

[0043] Step 2, the reaction product enters the deheptanizer for pre-fractionation after gas-liquid separation in the low-pressure separator, and most of the heptane in the reaction product is separated, and then the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com