Preparation method of bonding-free polyurethane lining mold

A polyurethane and lining mold technology, applied in the field of prefabricated buildings, can solve the problems of low body strength, poor bonding, tearing, etc., and achieve the effect of delaying the speed of rusting again, eliminating the existence of air, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing a non-adhesive polyurethane liner mold, carried out according to the following steps:

[0055] (1) Preparation of components A and B of polyurethane lining mold raw materials

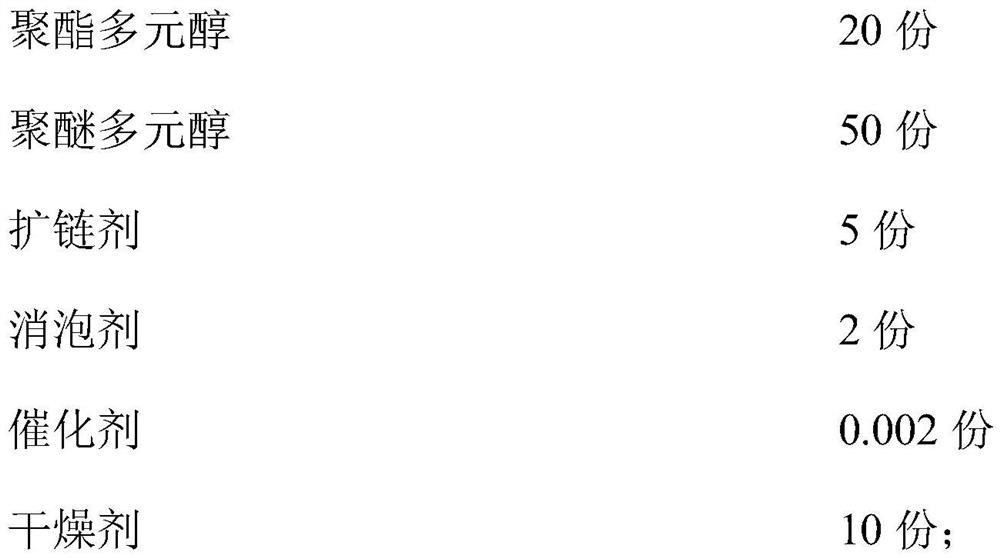

[0056] Accurately weigh polyester polyol, polyether polyol, extender, defoamer, catalyst and desiccant according to the following mass parts, and then stir and mix evenly to obtain component A;

[0057] Based on the sum of the mass of polyester polyol and polyether polyol as 100 parts, the mass parts of each component in component A are:

[0058]

[0059] Accurately weigh the compound containing -NCO group and polyether polyol according to the following mass ratio, put it into the container, stir and react at 80-100°C for 2-6h, and after passing the -NCO value test, you can get the following B component;

[0060] The mass parts of each component in the B component are:

[0061] Containing -NCO compound 50 parts

[0062] 30 parts of polyether polyols;

[0063] After ...

Embodiment 2

[0092] Compared with the above-mentioned Example 1, the molar ratio of reactive groups in [OH] / [NCO] was changed from 0.99 to 1.02, so as to achieve the effect described in Example 2 in Table 2 below.

Embodiment 3

[0094] Compared with the above-mentioned Example 1, the molar ratio of the reactive groups in [OH] / [NCO] was changed from 0.99 to 1.0, and the number of parts of phthalic anhydride polyester in the preparation was increased from 20 to 30 parts, and the polyether polyether The number of parts of alcohol 2 was reduced from 30 to 20 parts, thereby achieving the effect described in Example 3 in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com