Cement-soil composite pipe pile integral forming machine and cement-soil composite pipe pile forming method thereof

A forming method and integral technology, which is applied in the directions of earthwork drilling, drilling equipment and methods, sheet pile walls, etc. The effect of reducing production costs and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

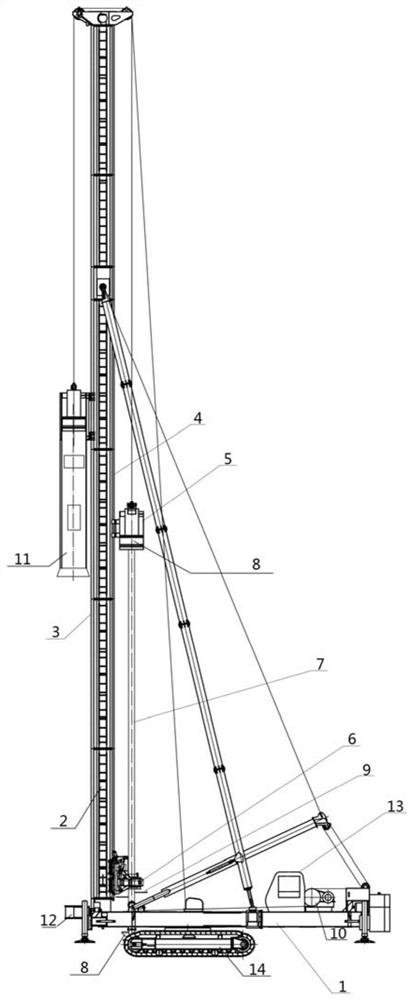

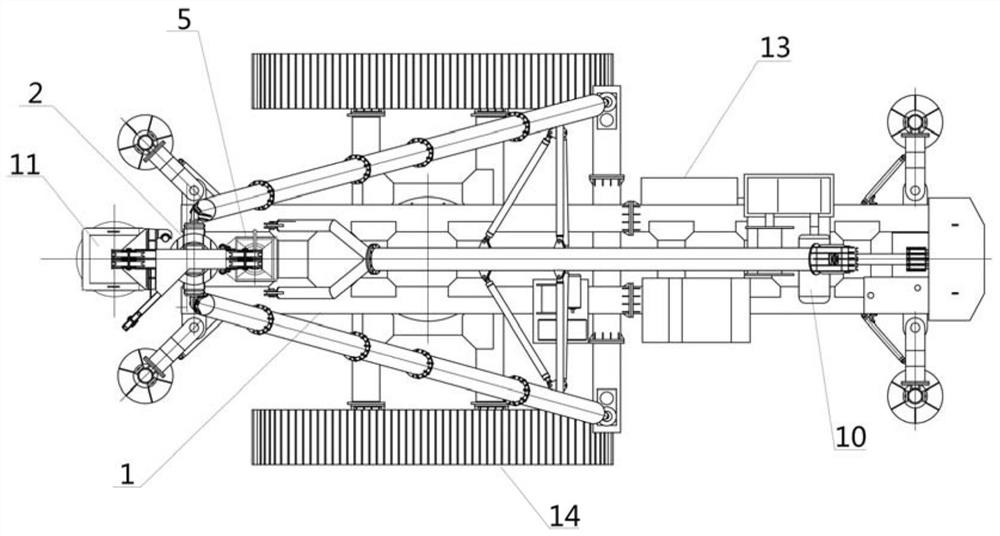

[0034] Such as Figure 1-2 A cement-soil composite pipe pile integral forming machine shown includes a crawler pile driver and a cement pile construction device, and the crawler pile driver includes a platform 1, a pile frame 2 and a pipe pile construction device, and the pile frame 2 is installed On the platform 1 , the pipe pile construction device and the cement pile construction device are respectively installed on opposite sides of the pile frame 2 , and both are parallel to the pile frame 2 .

[0035] The integral forming machine of the present invention is an integral cement-soil composite pipe pile construction machine integrating a cement pile construction device and a pipe pile construction device, wherein the cement pile construction device and the pipe pile construction device are 180 degrees parallel on the pile frame Arranged on both sides of the pile frame. During use, the positioning and construction of cement-soil piles and pipe piles can be completed success...

Embodiment 2

[0053] A cement-soil composite pipe pile forming method, the forming method uses the integral forming machine described in Example 1. Described forming method comprises the steps:

[0054] S1: Put the integral molding machine in place, and position and level the cement pile construction device;

[0055] S2: Start the cement slurry mixer to prepare cement slurry;

[0056] S3: Start the cement pile construction device, and the cement slurry enters the drill pipe of the cement pile construction device through the high-pressure rotary spray faucet of the cement pile construction device under the action of the grouting pump, and the drill pipe automatically Drill down to the design depth;

[0057] S4: The drill pipe is sprayed and stirred at the design depth through the horizontal nozzle for 30s±5s, then starts to lift, and keeps the slurry feeding continuously;

[0058] S5: Repeat steps S4 and S5 to sink and lift the high-pressure jet stirring section that needs to be re-stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com