Preparation method of bulletproof insert plate, electronic equipment and storage medium

A bulletproof insert, bulletproof fiber technology, applied in protective equipment, offensive equipment, protective equipment, etc., can solve the problems of easy sputtering of fragments, secondary damage, etc., to improve the protection coefficient, reduce energy absorption pressure, and improve bulletproof capability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

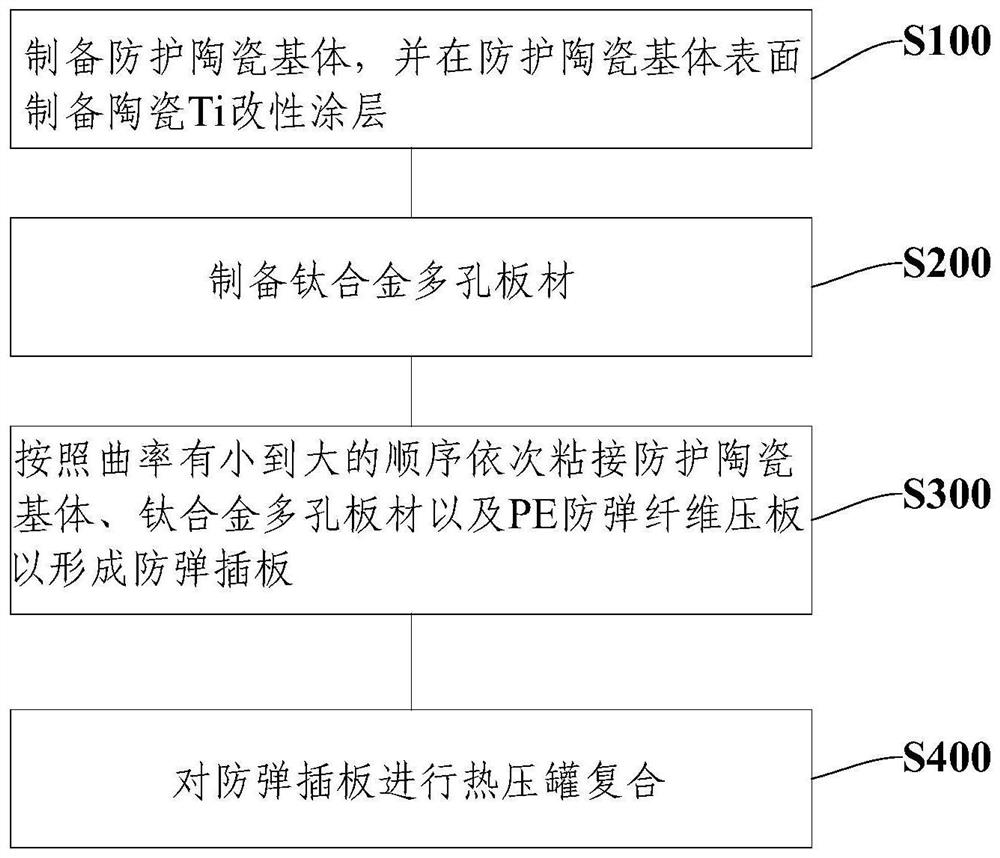

[0039] Such as figure 1 As shown, the present invention provides a kind of preparation method of bulletproof board, comprising:

[0040] S100, preparing a protective ceramic substrate, and preparing a ceramic Ti modified coating on the surface of the protective ceramic substrate;

[0041] S200, preparing a titanium alloy porous plate;

[0042] S300. Bond the protective ceramic substrate, titanium alloy porous plate and PE bulletproof fiber plate in order of curvature from small to large to form a bulletproof insert;

[0043] S400, performing autoclave compounding on the bulletproof plate.

[0044]The preparation method of the bulletproof board provided by the embodiment of the present invention, by improving the structure of the traditional bulletproof board, using a titanium alloy porous plate as a flexible transition layer, relying on its own structural advantages, the stress is further released in the transition layer, ensuring that the protective ceramics On the basis o...

Embodiment 1

[0066] Embodiment 1. Preparation of a protective ceramic substrate with a thickness of 5.5 mm:

[0067] First, take D50, 0.5 micron boron carbide powder 92%, rare earth oxide RE1.5%, and other sintering aids YO3%. The protective ceramic matrix is prepared through the processes of drum mixing, spray granulation, cold pressing, hot pressing and sintering;

[0068] Secondly, ultrasonically wash the protective ceramic substrate with pure water at 30 degrees for 8 hours. After taking it out, use acetylacetonate (10g / L) and sodium hydroxide (7g / L) to emulsify and wash it for 3 times, and then use flowing pure water Wash 5 times. Place it in an oven at 120°C for 10 hours and take it out for later use. The Ti coating is deposited by the chemical vapor deposition method. The area of the ceramic protective substrate is linearly related to the mass of the titanium powder, which is about 4g / square decimeter. The material ratio of the titanium bromine reactor is 1:5. 10 degrees per ...

Embodiment 2

[0075] Embodiment 2. Preparation of a protective ceramic substrate with a thickness of 9.5 mm:

[0076] First, take 92% of D50, 1.0 micron boron carbide powder, 1.5% of rare earth oxide RE, and 3% of other sintering aids. The protective ceramic matrix is prepared through the processes of drum mixing, spray granulation, cold pressing, hot pressing and sintering;

[0077] Secondly, ultrasonically wash the protective ceramic substrate with pure water at 30 degrees for 8 hours. After taking it out, use acetylacetonate (10g / L) and sodium hydroxide (7g / L) to emulsify and wash it for 3 times, and then use flowing pure water Wash 5 times. Place it in an oven at 120°C for 10 hours and take it out for later use. The Ti coating is deposited by the chemical vapor deposition method. The area of the ceramic protective substrate is linearly related to the mass of the titanium powder, which is about 3g / square decimeter. The material ratio of the titanium bromine reactor is 1:5. 10 degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com