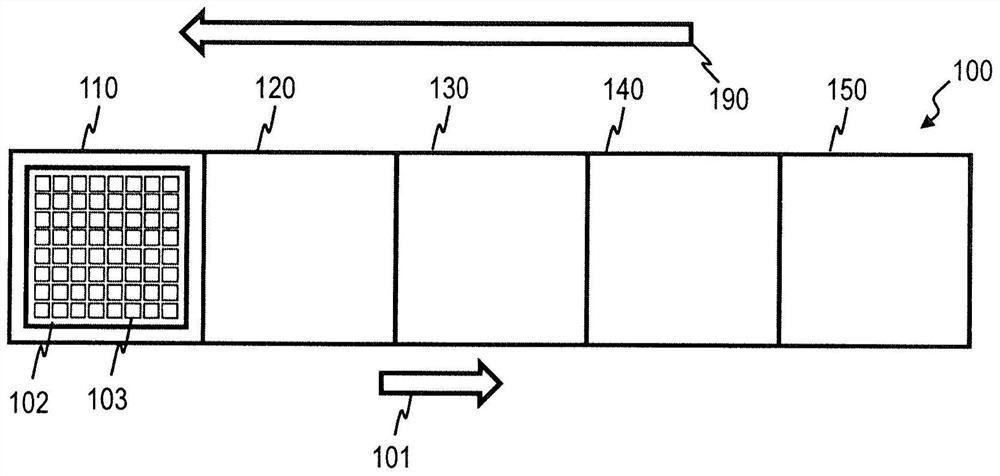

Continuous flow system and method for coating substrates

A technology of equipment and substrates, applied in the field of continuous equipment, can solve the problems of increasing the complexity and error rate of continuous equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

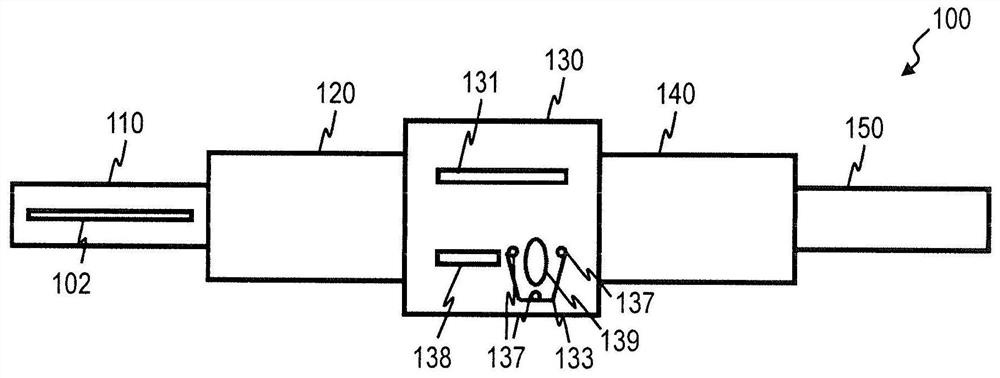

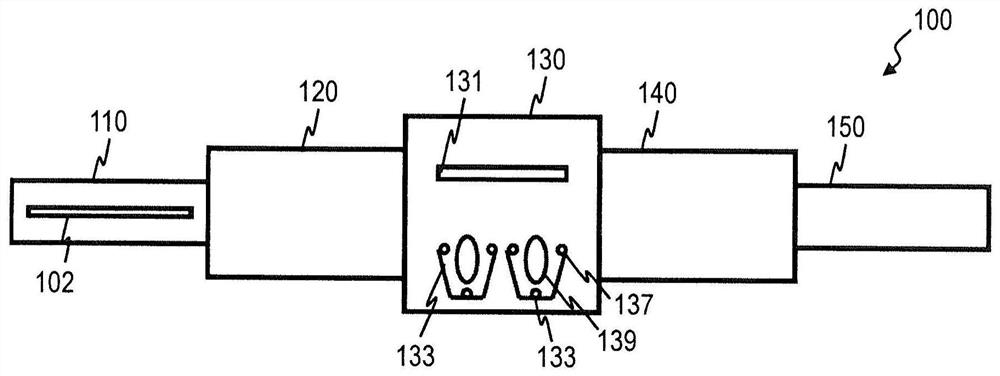

[0258] Aspect 1: Continuous equipment for coating substrates, including:

[0259] a processing module or processing modules; and

[0260] A vacuum isolation chamber for isolating substrates in or for isolating substrates, wherein the vacuum isolation chamber includes a chamber for receiving a substrate carrier having a plurality of substrates.

[0261] Aspect 2: The continuous apparatus of aspect 1, wherein the vacuum isolation chamber further comprises a fluid channel arrangement for evacuating and filling the chamber, wherein the fluid channel arrangement has a first channel for evacuating and filling the chamber and a fluid channel arrangement for evacuating and filling the chamber A second channel of the chamber is filled, wherein the first channel and the second channel are disposed on opposite sides of the chamber.

[0262] Aspect 3: The continuous plant according to aspect 1 or aspect 2, wherein at least one processing module has a plasma source, a gas supply for suppl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com