Continuous deslagging device of fluidized bed gasification furnace and deslagging method of continuous deslagging device

A fluidized bed gasification furnace, gasification furnace technology, applied in the mechanical details of the gasification device, granular/powdered fuel gasification, combustible gas production, etc., can solve the problem of large water consumption, low efficiency of slag removal, and difficult operation and other problems, to achieve the effect of reducing slagging cost, improving slagging efficiency, and simplifying slagging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

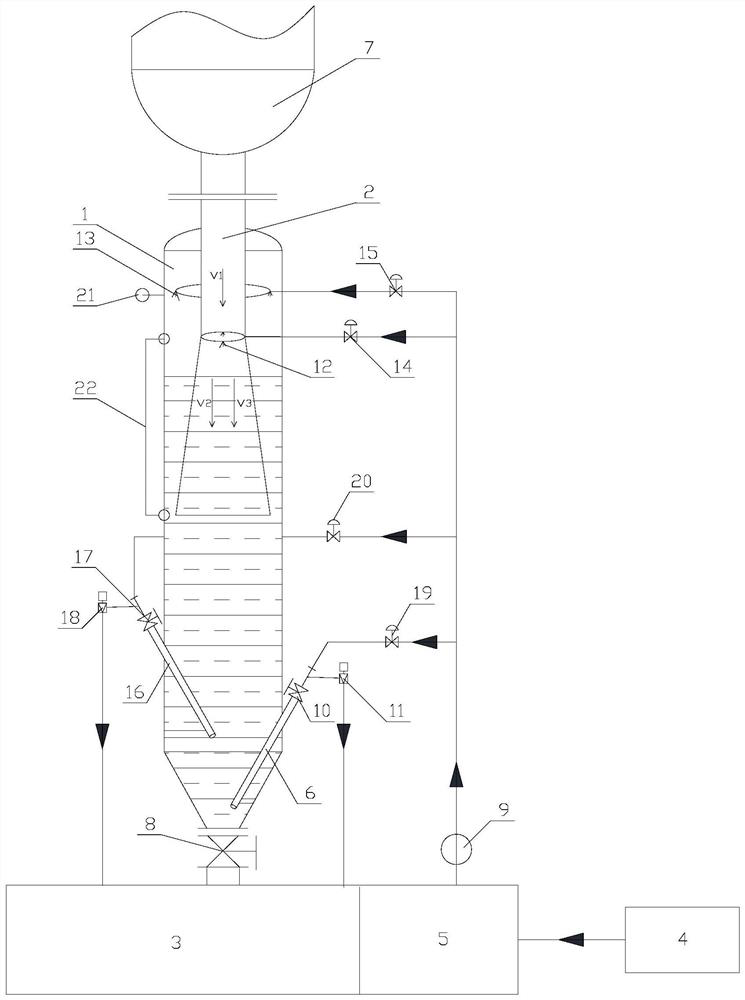

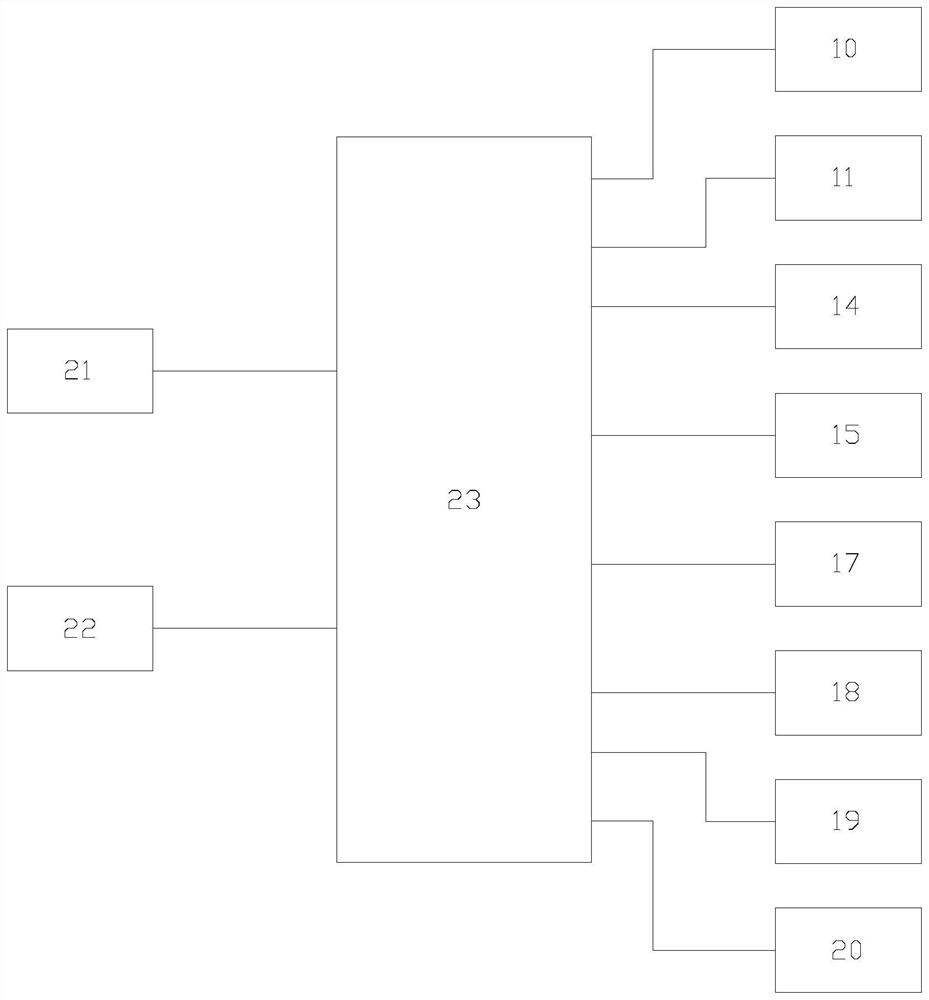

[0029] Embodiment 1: as Figure 1-2 As shown, a continuous slagging device for a fluidized bed gasifier 7 includes a slagging tank 1, a slag lowering channel 2, a slag pool 3, a water source 4, a clean water pool 5 and a first slagging pipe 6; The top of the slag tank 1 is fixed with a lower slag channel 2, and the top of the lower slag channel 2 communicates with the slag outlet of the gasifier 7; connected; the pipeline between the slag tank 1 and the slag pool 3 is provided with a drain valve 8; the overflow port of the slag pool 3 and the water source 4 are all connected with the water inlet of the clean water pool 5; the water outlet of the clean water pool 5 is connected with the The water inlet of the circulation pump 9 is connected, and the water outlet of the circulation pump 9 is connected with the water inlet of the slag discharge tank 1; the first slag discharge pipe 6 is fixed on the side wall below the slag discharge tank 1 obliquely; The slag inlet end of 6 is ...

Embodiment 2

[0036] Embodiment 2: utilize the slagging method of embodiment 1 slagging device, it comprises the following steps:

[0037] (1) The ash falls from the lower slag channel 2 to the surface of the solution and forms a scum layer. At the same time, the inner spray head 12 in the lower slag channel 2 sprays water, and the spray water carries the scum layer to settle rapidly, so that the ash and slag Settled to below the slagging tank 1;

[0038] (2) Open the first quick-opening valve 10 and the first decompression angle valve 11, and the ash solution in the bottom of the slag discharge tank 1 is squeezed from the first slag discharge pipe 6 into the slag pool 3 under the action of pressure; The ash and slag solution at the bottom of the slag discharge tank 1 passes through the first slag discharge pipe 6 to continuously reduce the pressure, and is discharged from high pressure to low pressure into the slag pool 3, which simplifies the slag discharge process and improves the slag d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com