Preparation technology of marinated duck byproducts and marinated duck byproducts

A preparation process and accessory technology, which is applied to the preparation process of braised duck accessories and the field of braised duck accessories, can solve the problems of singleness and affect the flavor of duck meat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: a kind of preparation technology of stewed duck side parts,

[0059] Stew 100kg of duck parts in 1021.5kg of brine, take out the duck parts and mix with 5kg of seasoning sauce;

[0060] The duck part is composed of duck neck, duck tongue, duck paw, duck head, duck wing and duck leg;

[0061] The brine is prepared from the following raw materials: 200kg of water, 800kg of broth, 8kg of white sugar, 4kg of edible salt, 2kg of chicken essence seasoning, 1kg of monosodium glutamate, 5kg of pepper, 0.5kg of pepper, 0.6kg of star anise, and 0.4kg of cinnamon; the broth is made of water It is blended with the barrel bone at a ratio of 5:1.

[0062] The seasoning juice is prepared from the following raw materials: 0.6kg brine (same as the brine above), 0.5kg chili oil, 0.5kg pepper oil, 0.1kg pepper powder, 1kg yeast extract, 1kg white sugar, 0.5kg monosodium glutamate, edible Salt 0.2kg, chicken broth powder essence 0.5kg, ethyl maltol 0.1kg.

[0063] The prep...

Embodiment 2-4

[0079] Embodiment 2-4: a kind of preparation technology of side part of braised duck,

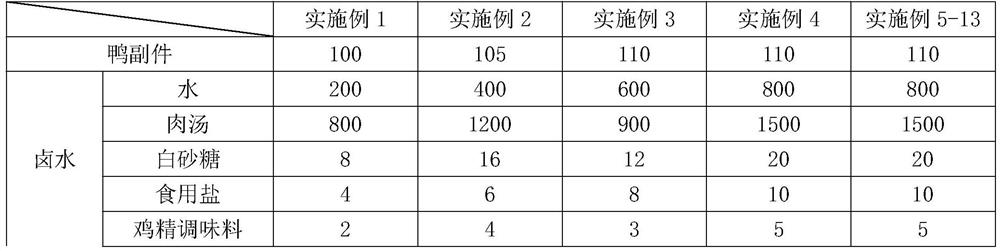

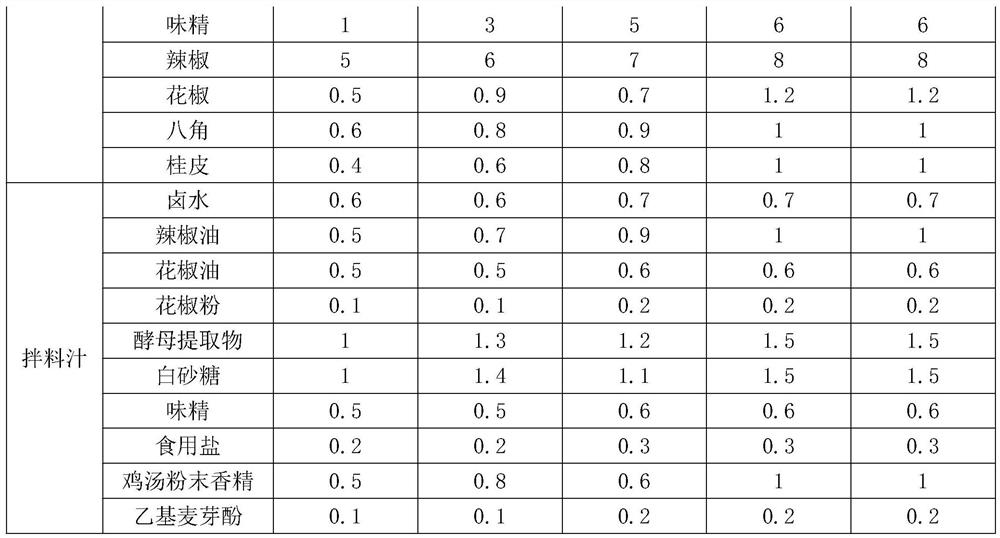

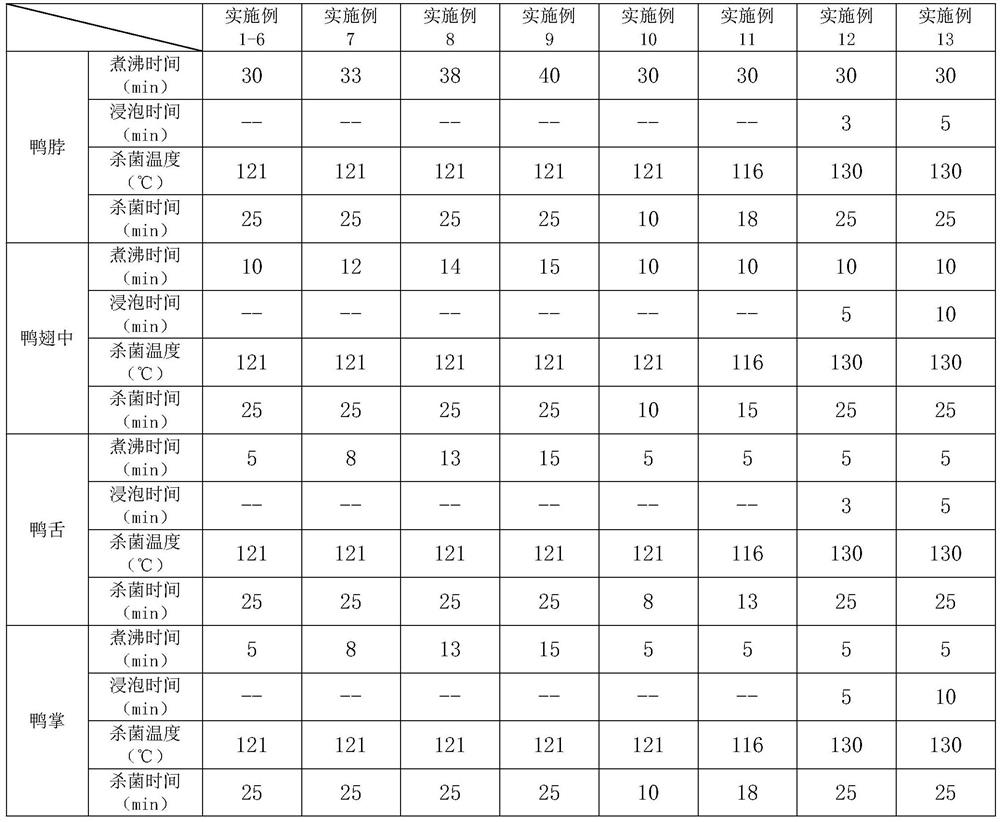

[0080] The difference from Example 1 is that the amount of each raw material is different, and the specific amount of each component and various process parameters are shown in Table 1 and Table 2 below, respectively.

Embodiment 5

[0081] Embodiment 5: a kind of preparation technology of stewed duck side part,

[0082] The difference from Example 1 is that the broth is made from water, tube bones and dried kelp, and the mass-number ratio of water, tube bones and dried kelp is 15:2:1.5. The preparation process of the broth in step S2 is as follows: add the bone and water in proportion, heat and mix at 100°C for 2 hours, lower the temperature to 80°C, add dry kelp in proportion and continue to boil for 20 minutes to obtain broth.

[0083] The specific dosages of the remaining components and various process parameters are shown in Table 1 and Table 2 below, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com