Preparation method of functionalized magnetic microspheres, magnetic microspheres and application thereof

A magnetic microsphere and functionalization technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of poor suspension of magnetic microspheres, high cost of waste liquid treatment, poor hydrophilicity, etc., and achieve high recovery rate and stable suspension. The effect of increased sex and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

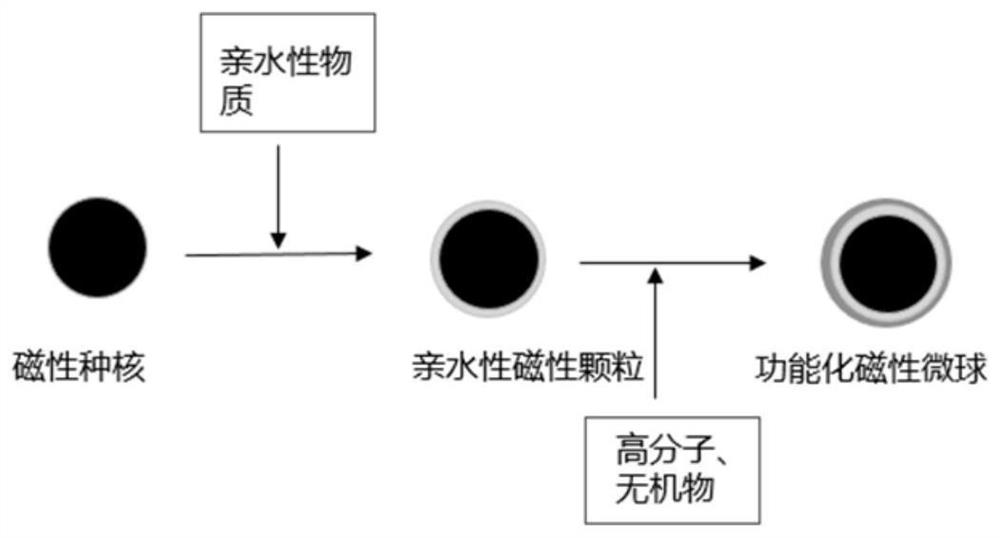

[0060] refer to figure 1 The schematic diagram of the preparation process shown in the preparation of functionalized magnetic microspheres, including the following steps:

[0061] Step 1: Preparation of magnetic bulbs

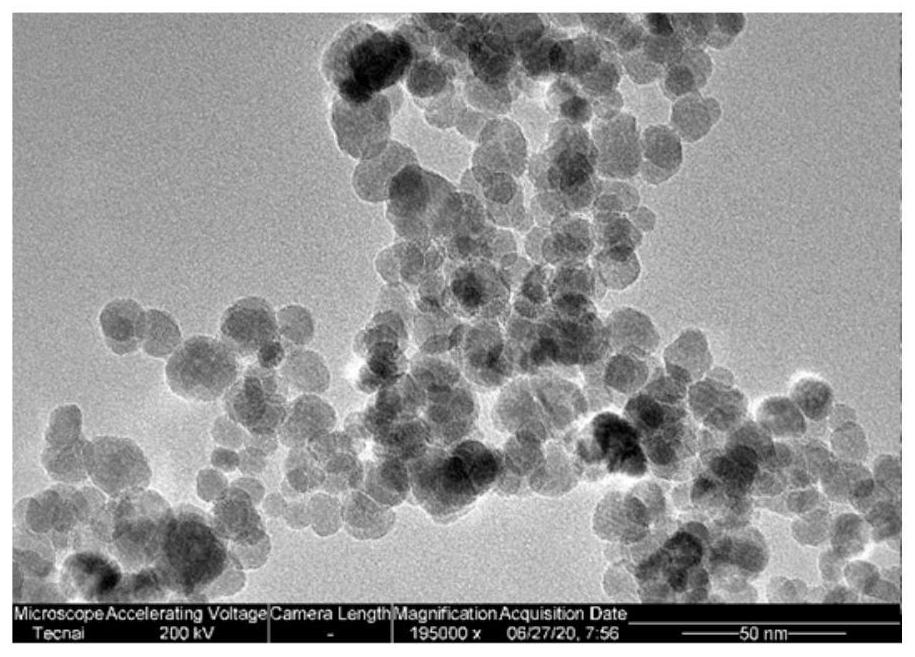

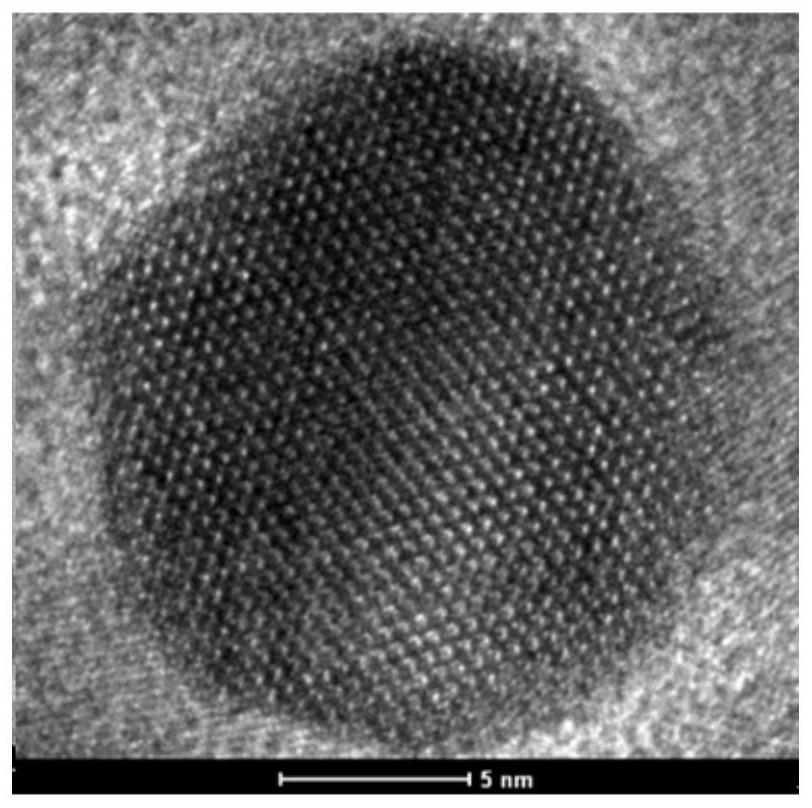

[0062] Take 10g of ferrous chloride tetrahydrate and 15g of ferric chloride hexahydrate in 150mL of ultrapure water, set the stirring speed to 200rpm, stir for 30min to fully mix the solution, then raise the temperature to 60°C, then add 10mL of ammonia water, and react After 30 minutes, the temperature was raised to 80°C and aged for 1 hour to obtain superparamagnetic nano-magnetic particles with a particle size of about 5-15 nm, that is, to obtain magnetic seed bulbs. figure 2 and image 3 show; combine figure 2 and image 3 It can be seen that the prepared magnetic seed bulbs are basically spherical, and have a good crystal structure, complete and uniform crystal shape, a particle size of about 10nm, and the magnetic seed bulbs have superparamagnetism....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com