Flexible resistive random access memory based on FeS2-ZrO2-rGo and preparation method of flexible resistive random access memory

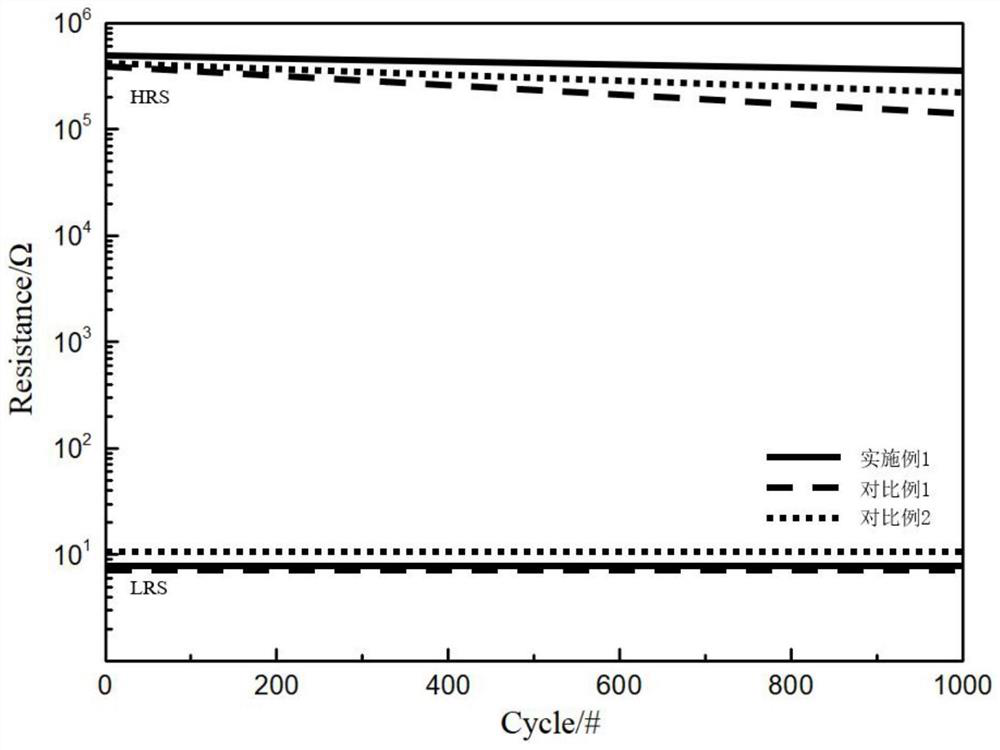

A technology of fes2-zro2 and resistive variable memory, which is applied in the field of memory, can solve the problems that the resistance variable performance and bending ability of storage capacity need to be improved, and the flexible RRAM technology is immature, so as to improve the resistance change ability, stability, and The effect of storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

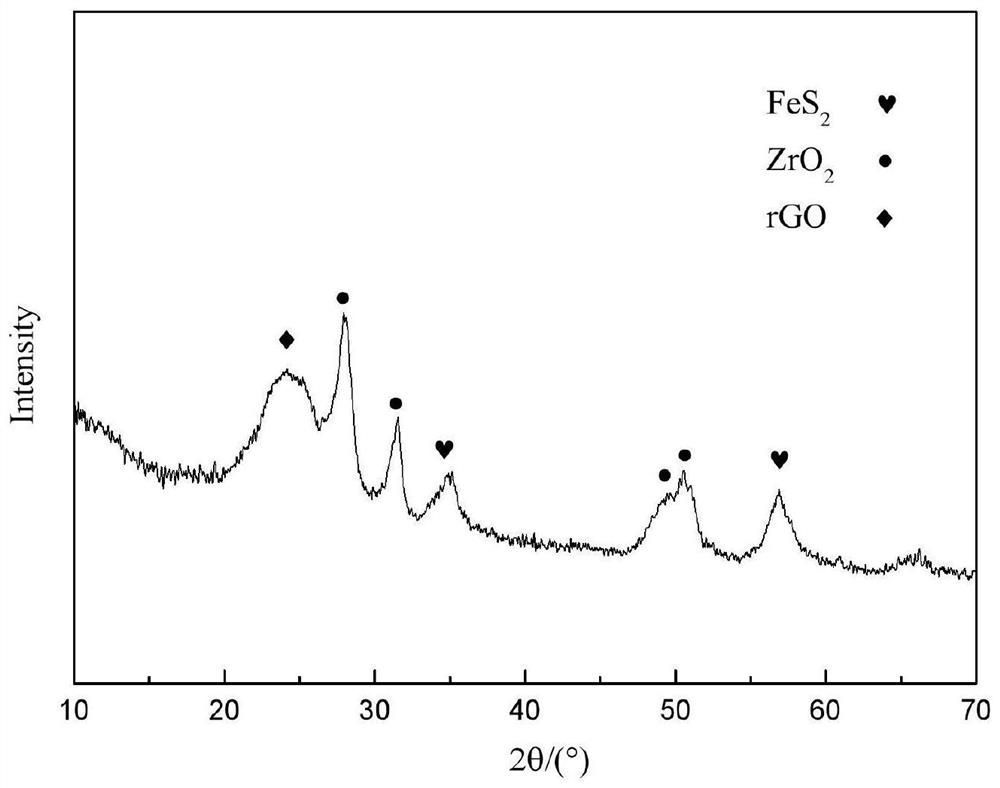

[0031]Step 1: Dissolve 4.98g of terephthalic acid in 62.3ml of DMF, stir at room temperature for 10min, then add 3.24g of ferric chloride to the solution, ultrasonicate for 5min; then drop 31.2 ml of absolute ethanol, stirred for 20 min, transferred the mixed solution to a reaction kettle and kept it at 100°C for 20 h, cooled to room temperature, washed alternately with DMF and absolute ethanol for 5 times, and dried in a vacuum freeze-drying oven. After drying, put the material in a muffle furnace, first raise it to 320°C at a speed of 3°C / min and keep it for 3h, then rise to 550°C at a speed of 1°C / min and then calcinate for 1.5h; after cooling to room temperature, put The product is placed in a tube furnace and passed into H 2 S, heated to 450°C and held for 70min to obtain FeS 2 Material.

[0032] Step two: the ZrOCl of 3.7g 2 ·8H 2 O and 0.97g urea were added to 61.7ml deionized water, stirred at room temperature for 20min; then 2.4g of FeS was added 2 And sonicate f...

Embodiment 2

[0036] Step 1: Dissolve 5.98g of terephthalic acid in 74.8ml of DMF, stir at room temperature for 15min, then add 4.86g of ferric chloride to the solution, ultrasonicate for 6min; then drop 24.9 ml of absolute ethanol, stirred for 15 minutes, transferred the mixed solution to a reaction kettle and kept at 90°C for 24 hours, cooled to room temperature, washed alternately with DMF and absolute ethanol for 5 times, and dried in a vacuum freeze-drying oven. After drying, put the material in a muffle furnace, first raise it to 320°C at a speed of 3°C / min and keep it warm for 2h, then raise it to 550°C at a speed of 1°C / min and then calcinate for 1.5h; after cooling to room temperature, put The product is placed in a tube furnace and passed into H 2 S, heated to 450°C and held for 67min to obtain FeS 2 Material.

[0037] Step 2: the ZrOCl of 4.9g 2 ·8H 2 O and 1.1g urea were added to 81.7ml deionized water, stirred at room temperature for 25min; then 3.6g of FeS was added 2 And...

Embodiment 3

[0041] Step 1: Dissolve 4.78g of terephthalic acid in 59.8ml of DMF, stir at room temperature for 12min, then add 3.68g of ferric chloride to the solution, and ultrasonicate for 7min; then drop 23.9 ml of absolute ethanol, stirred for 16 minutes, transferred the mixed solution to a reaction kettle and kept at 96°C for 23 hours, cooled to room temperature, washed alternately with DMF and absolute ethanol for 5 times, and dried in a vacuum freeze-drying oven. After drying, put the material in a muffle furnace, first raise it to 320°C at a speed of 3°C / min and keep it warm for 2.5h, then raise it to 550°C at a speed of 1°C / min and then calcinate for 1h; after cooling to room temperature, put The product is placed in a tube furnace and passed into H 2 S, heated to 450°C and held for 63min to obtain FeS 2 Material.

[0042] Step two: the ZrOCl of 3.78g 2 ·8H 2 O and 0.86g urea were added to 63ml deionized water, stirred at room temperature for 29min; then 2.7g of FeS was added ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap