Fly ash hollow microsphere pulsation solid-liquid fluidization sorting recovery device and method

A technology of hollow microbeads and recovery devices, which is applied in the direction of chemical instruments and methods, solid separation, wet separation, etc., can solve the problem of low recovery rate and grade of hollow microbeads sorting, affecting the utilization efficiency of fly ash resources, separation Eliminate problems such as cumbersome selection process, and achieve the effects of energy saving of equipment, improvement of grade, and increase of settlement area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

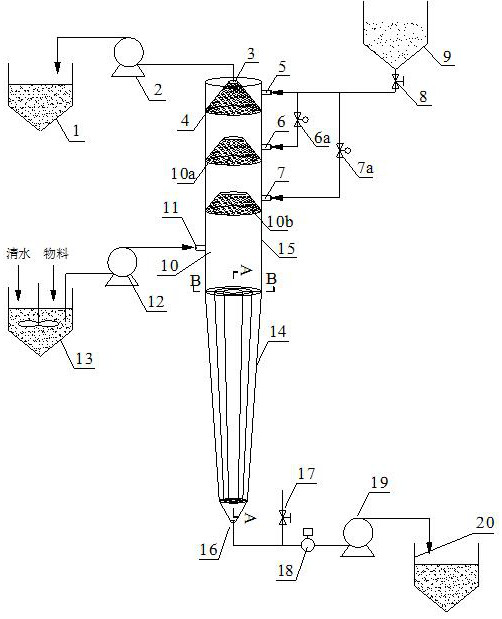

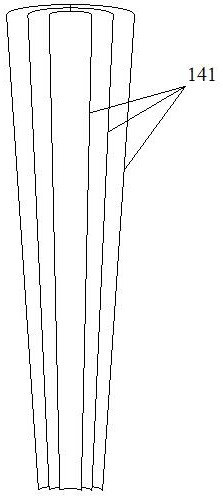

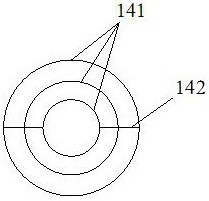

[0036] like Figure 1 to Figure 3 As shown, a fly ash hollow microbead pulsating liquid-solid fluidized separation and recovery device includes a sorting bed 10, which is made of high-strength wear-resistant materials in order to improve the service life of the sorting bed 10; The sorting bed body 10 includes a vertical cylinder 15 and an inverted cone sleeve 14 from top to bottom, the bottom of the vertical cylinder 15 communicates with the top of the inverted cone sleeve 14, the top of the vertical cylinder 15 is sealed, and the vertical cylinder 15 inner diameter is 300mm, length is 1000mm;

[0037] The top of the vertical cylinder 15 is provided with an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap