Coke oven heating system and exchange heating control method thereof

A heating system and coke oven technology, which is applied in the heating of coke ovens, coke ovens, and combustible gas heating coke ovens, etc., can solve problems such as gas explosions in coke oven regenerators or flue parts, shorten troubleshooting time, The effect of improving safety performance and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

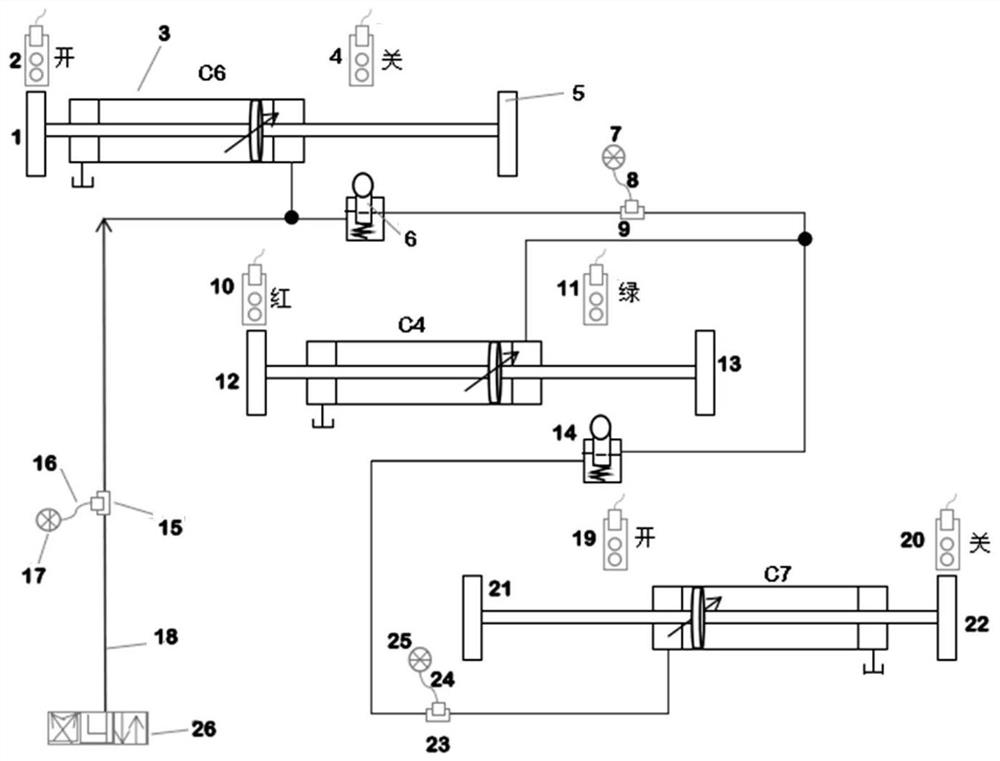

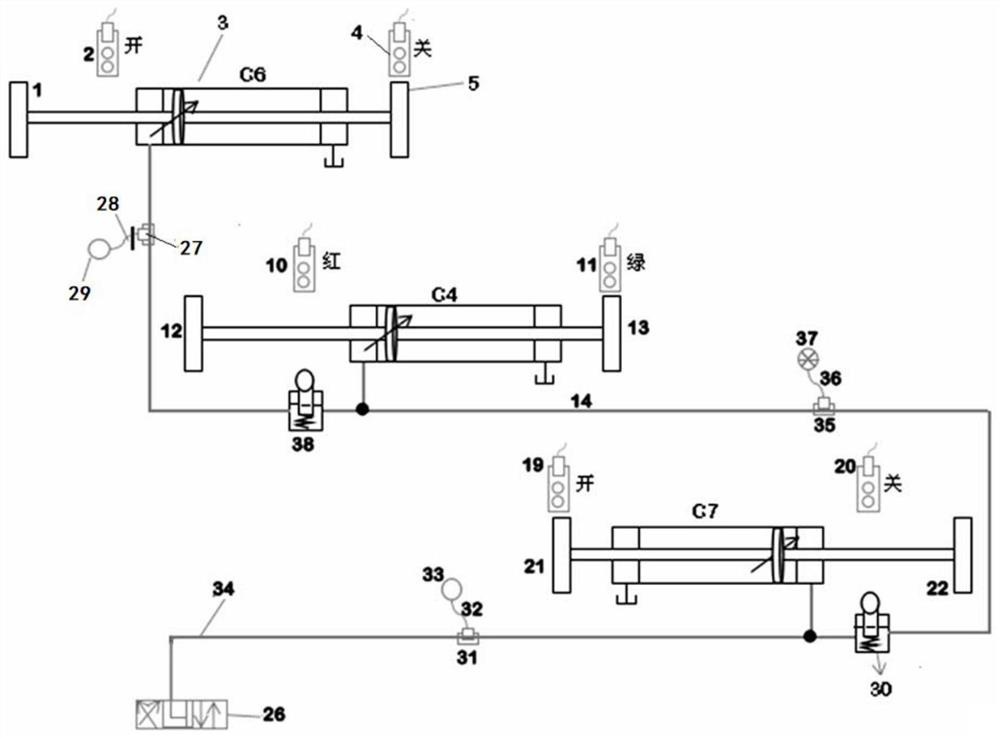

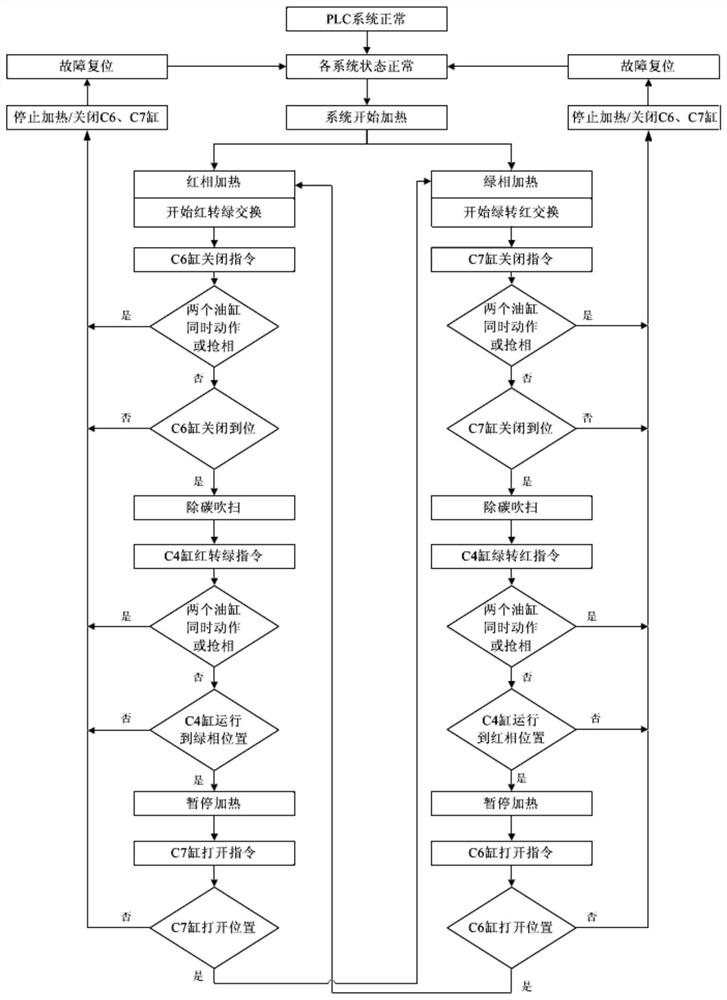

[0044] Such as figure 1 , figure 2 The structure of the present invention expressed is a coke oven heating system, which includes a plurality of combustion chambers, and adopts double-connected fire channels to alternate and reverse heating, that is, the combustion chambers are divided into two groups, and are respectively converted into two working states, namely : When the first working state is switched, the first group of combustion chambers enters the coal gas, and the second group of combustion chambers discharges the exhaust gas; on the contrary, when the second working state is converted, the second group of combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com