Efficient baking device for electronic component processing

A technology for electronic components and baking devices, applied in drying, dryer, drying room/container and other directions, can solve the problems of easily burnt components, inconvenient operation, slow baking speed, etc., and achieve uniform baking. , the effect of fast baking speed and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

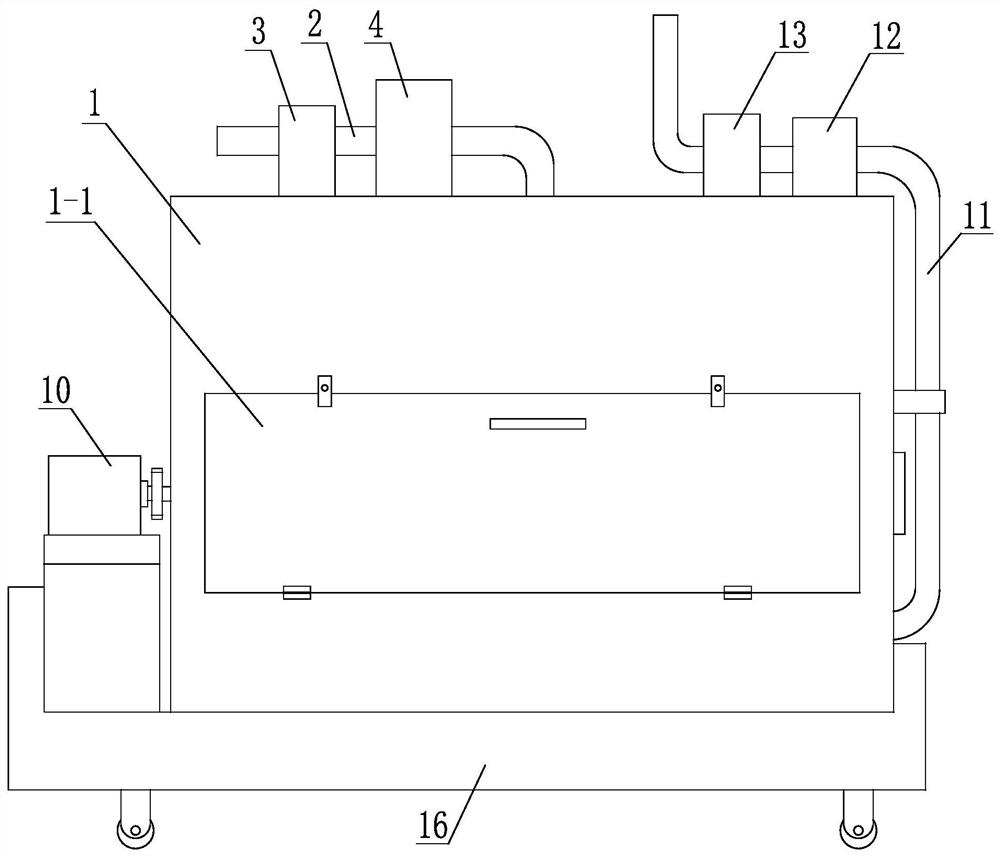

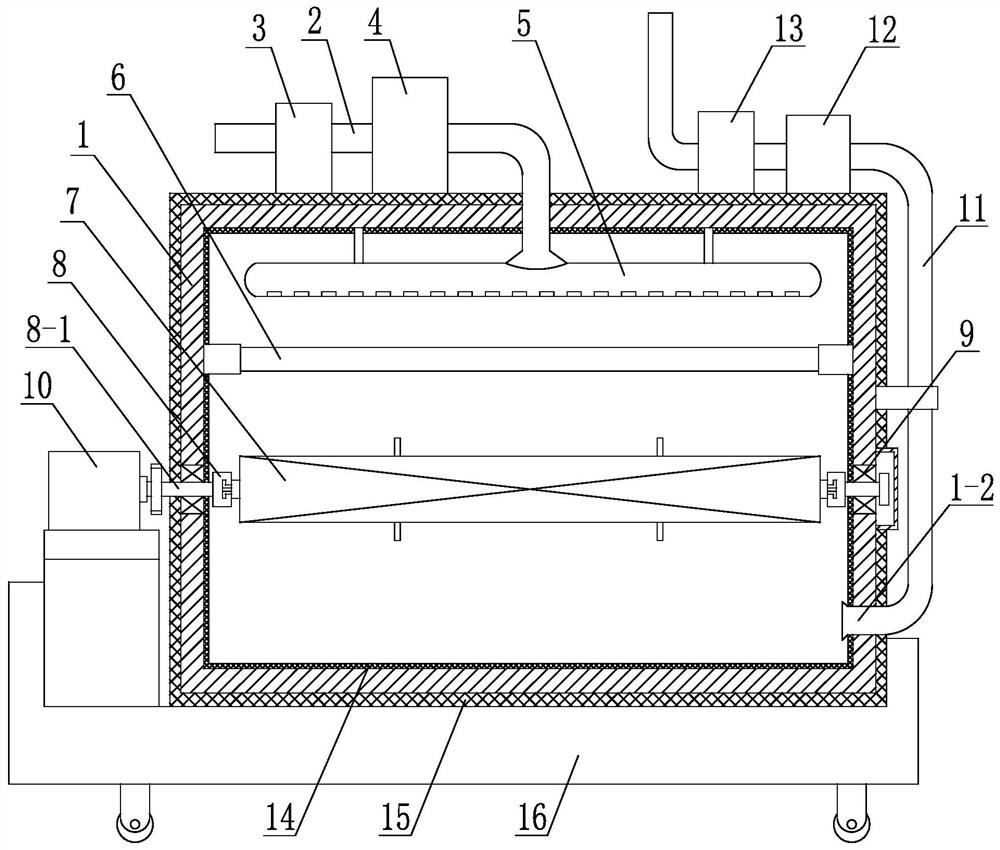

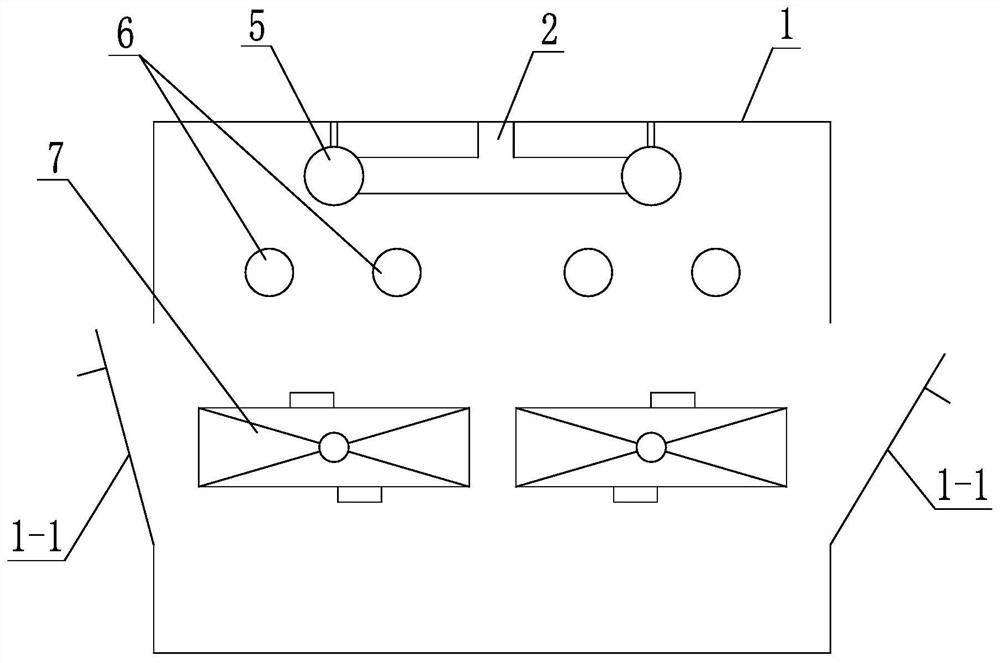

[0017] A high-efficiency baking device for processing electronic components, such as figure 1 , figure 2 , image 3 As shown, it includes an oven 1, the front and / or back of the oven 1 are provided with an oven door 1-1, the top of the oven 1 is equipped with an air inlet pipe 2, and an air filter I3 and an induced draft fan are connected to the air inlet pipe 2. Ⅰ4. The air outlet of the air inlet pipe 2 passes through the top of the oven 1 and enters the inner cavity of the oven 1, and communicates with at least one air spray pipe 5. The air spray pipe 5 is horizontally suspended in the oven 1 by a hanger and connected to the door 1 1 parallel, the pipe wall of the blast pipe 5 is uniformly provided with a plurality of air holes, and at least one electric grilling pipe 6 parallel to the axial direction of the blast pipe 5 and having the same length as the blast pipe 5 is arranged below the blast pipe 5. The bottom of the tube 6 is provided with a wire mesh box 7 which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com