Blocker-type forging method of travelling block lifting ring for petroleum drilling machine lifting system

A lifting system, tire die forging technology, applied in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of reducing mechanical properties, high wire cutting costs, affecting service life, etc. Achieve the effect of excellent mechanical properties, less machining allowance, and good use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

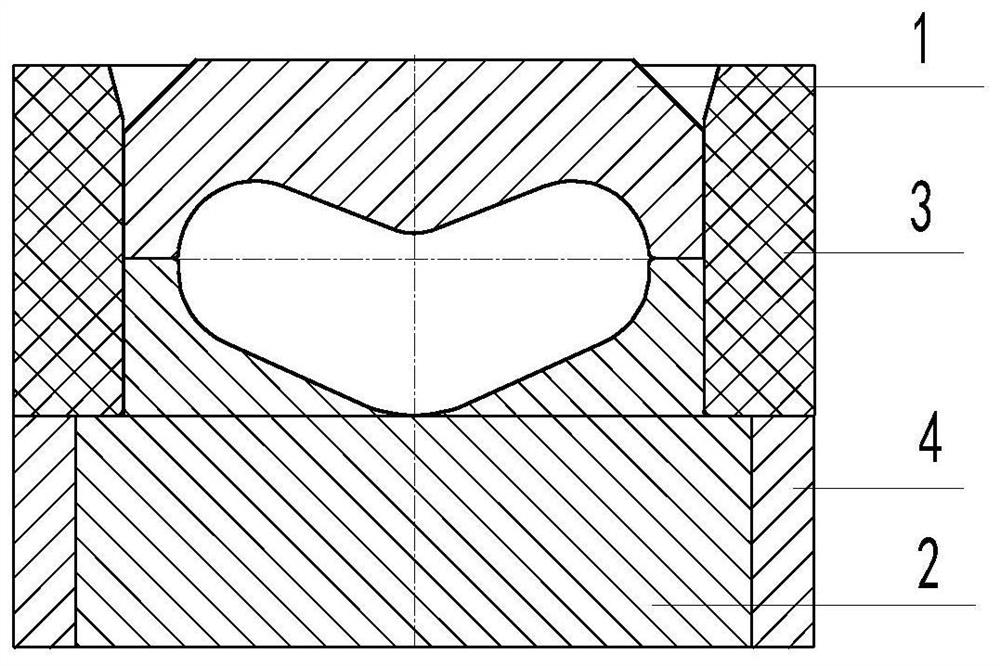

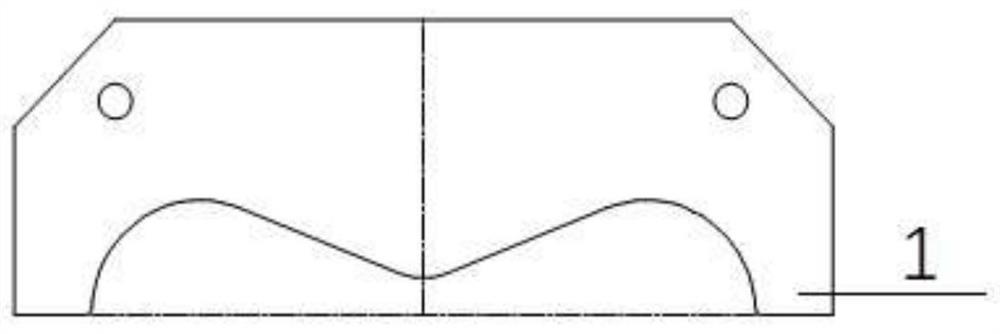

[0054] 1. Take the lifting ring of YC450 traveling car as an example, formulate the forging drawing according to the part drawing, design the tire mold, calculate the weight of the forging, the weight of the blanking material, the specification of the blanking material, determine the initial forging and final forging temperature, forging heat times, and the thickness of the billet , forging deformation process, forging equipment and cooling after forging, etc., to prepare forging process.

[0055] 2. According to the shape and size of the forging, the weight of the forging is calculated to be 390kg, and the forging is performed twice. Considering the fire consumption, the blanking weight is 410kg, and the blanking size is about Φ400×415.

[0056] 3. Heating, heating to the initial forging temperature of 1180-1200°C according to the heating specification, and keeping it warm for 2 hours.

[0057] 4. Free forging and upsetting billet, the billet is round cake shape, the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com