Micro-indentation tooth plate

A micro-indentation, tooth plate technology, applied in the direction of wrench, wrench, manufacturing tools, etc., can solve the problem of difficult to control the indentation of the clamping degree of the tooth plate, avoid poor welding, no solder coating, good sharpness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

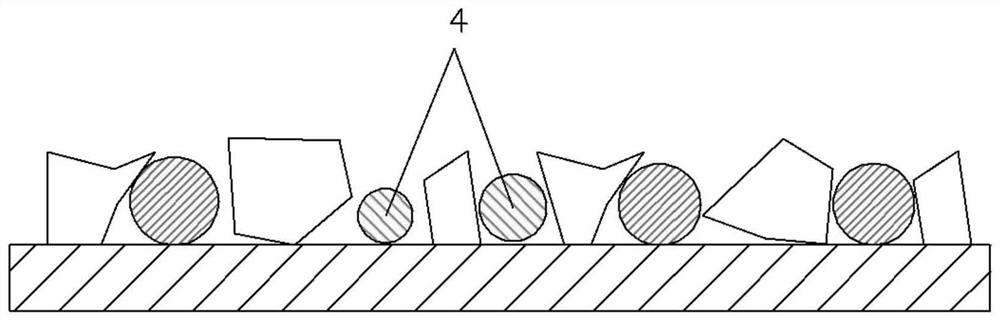

[0035] To prepare a micro-indentation tooth plate for casing pliers, it is required to have small indentation on the casing, small surface damage, and normal tightness.

[0036] Solution: Use cemented carbide particles as the cemented carbide anvil material of grade YG8, with a particle size of 35 / 40 mesh. The brazing solder is a nickel-based alloy of BNi2 grade, with a particle size of 35 mesh to 100 mesh. Using vacuum brazing process

[0037] The substrate of the micro-indentation dental plate is steel, and the substrate is selected from steel such as 30Cr steel.

[0038] The micro-indentation dental plate is prepared through the following steps:

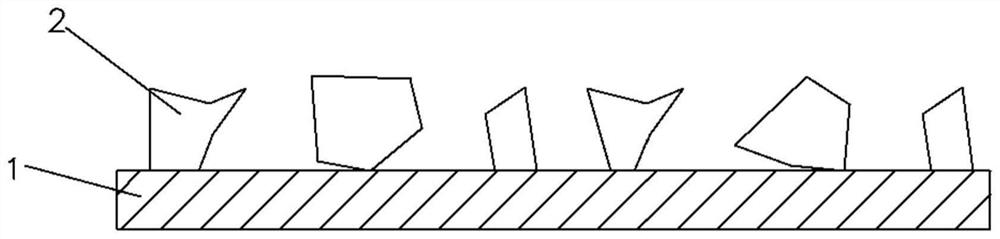

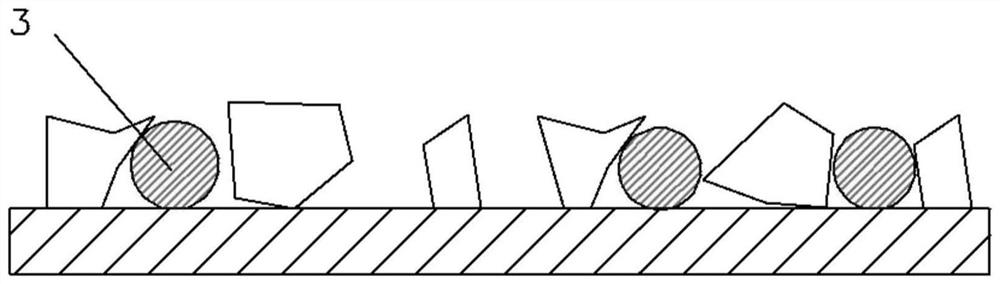

[0039] (1) Spray or brush a layer of adhesive on the surface of the tooth plate. The adhesive is oily pressure-sensitive adhesive, which is mixed with acetone at a volume ratio of 1:2.5.

[0040] (2) Sprinkle cemented carbide particles, the cemented carbide particles are evenly distributed, and the average spacing of the distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com