Organic sewage treatment and recovery system

A recovery system and organic sewage technology, applied in biological water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem that the activated sludge treatment device cannot meet the requirements and the high cost of organic sewage recycling , low carbon source utilization efficiency and other issues, to achieve the effects of high biogas production efficiency, low treatment and recovery costs, and fast decomposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with the accompanying drawings and specific embodiments:

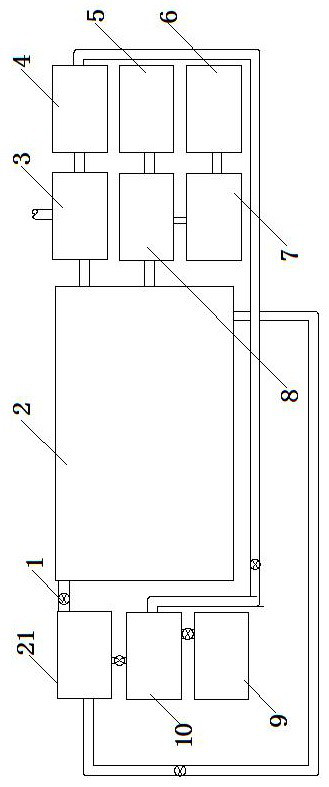

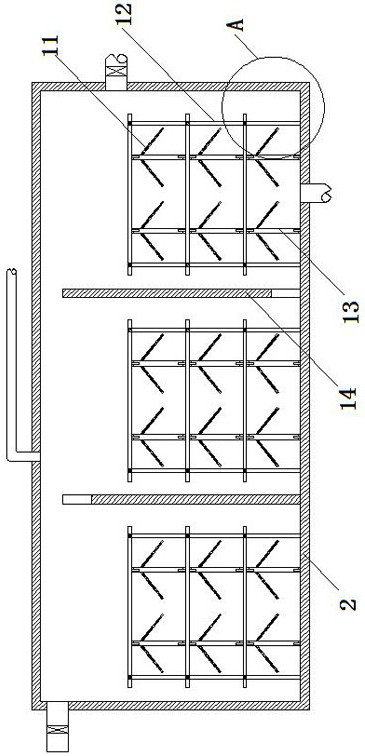

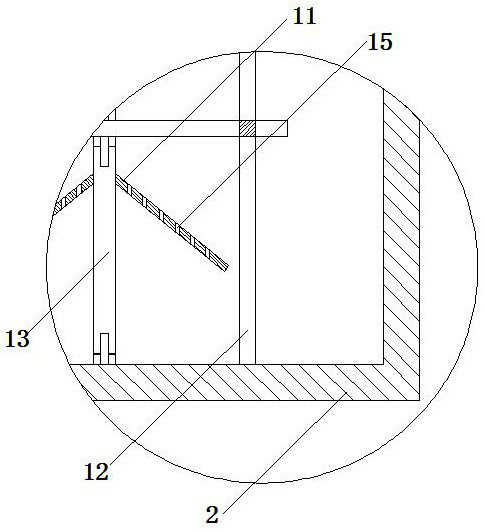

[0038] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, the organic sewage treatment and recovery system of the present invention includes a sewage tank 9 , an acidification tank 10 , a fermentation tank 2 , a desulfurization tower 3 , an acid liquid tank 4 , a strain return tank 21 and a filter press device 8 . A first pump is provided between the sewage tank 9 and the acidification tank 10 . The sewage in the sewage tank 9 is pumped into the acidification tank 10 through the first pump. The acidification tank 10 is communicated with the sulfuric acid solution device. The acidification tank 10 is communicated with the strain return tank 21 through pipelines and pumps. The front end of the fermentation tank 2 is provided with a feeding port, and the rear end is provided with a feeding port. The feed port communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com