Preparation method of fishing net thread processing enhancer

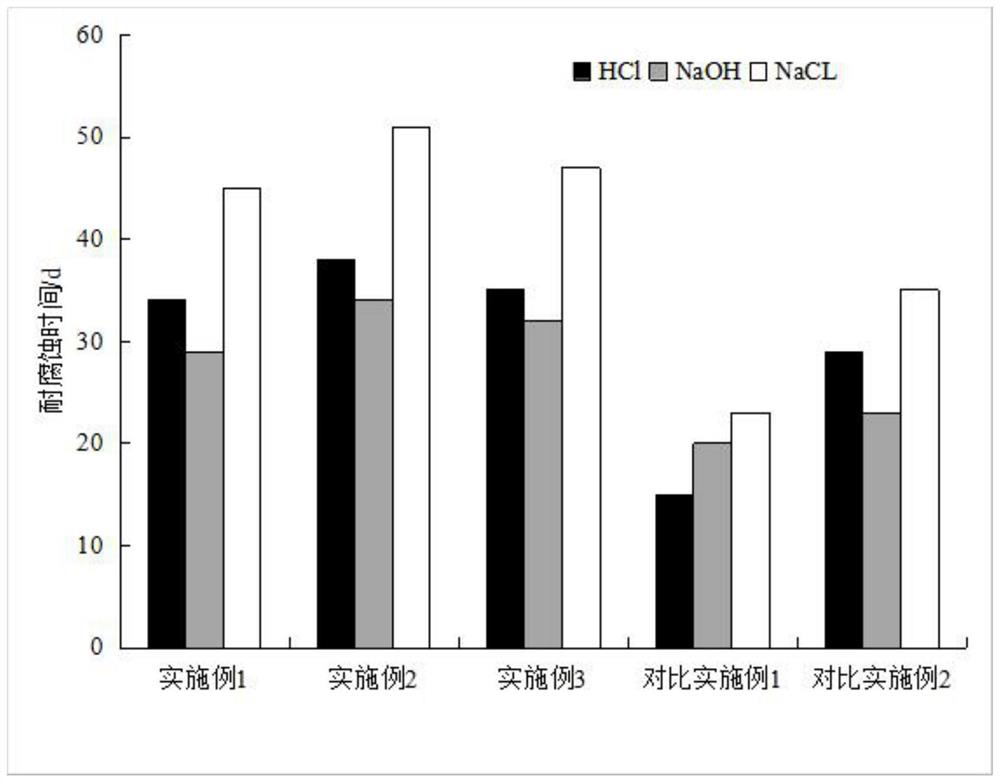

A technology of reinforcing agent and fishing net line, applied in the direction of coating, etc., can solve the problems of weakening the improvement effect of fishing net line, inability to overcome agglomeration, unstable performance, etc., to improve acid, alkali and salt corrosion resistance, mechanical properties, specific surface area increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

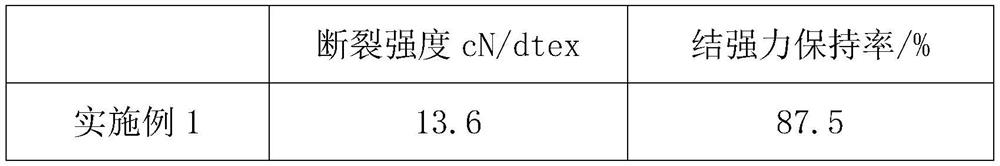

Examples

Embodiment 1

[0025] A preparation method for a fishing net line processing enhancer, comprising the steps of:

[0026] (1) Preparation of modified filler:

[0027] a. The fatty acid sorbitan and sodium dodecylbenzenesulfonate are placed in the reactor together at a weight ratio of 1:3, and after the temperature in the reactor is raised to 70°C, under constant temperature conditions, the Add fulvic acid dropwise at a constant rate, then add ammonia water dropwise at a constant rate, add dropwise while stirring, add graphene to the reaction after completion, continue stirring for 2 hours, and after high temperature and high pressure treatment for 50 seconds, quickly release the pressure to normal pressure, take out the mixture and pump Filter and dry to obtain material A for subsequent use;

[0028] b. Immerse the material A obtained in operation a into the modification solution, then place the ultrasonic probe at 2cm below the surface of the modification solution, perform ultrasonic treatm...

Embodiment 2

[0040] A preparation method for a fishing net line processing enhancer, comprising the steps of:

[0041] (1) Preparation of modified filler:

[0042]a. The fatty acid sorbitan and sodium dodecylbenzenesulfonate are placed in the reactor together according to the weight ratio of 1:3.5. After the temperature in the reactor is raised to 75°C, under constant temperature conditions, the Add fulvic acid dropwise at a constant rate, then add ammonia water dropwise at a constant rate, and add dropwise while stirring. After completion, add graphene to the reaction, continue stirring for 2.5 hours, and after high temperature and high pressure treatment for 55 seconds, quickly release the pressure to normal pressure, and take out the mixture Suction filtration, drying to obtain material A for subsequent use;

[0043] b. Immerse the material A obtained in operation a into the modifying solution, then place the ultrasonic probe at 2.5cm below the surface of the modifying solution, perfor...

Embodiment 3

[0055] A preparation method for a fishing net line processing enhancer, comprising the steps of:

[0056] (1) Preparation of modified filler:

[0057] a. The fatty acid sorbitan and sodium dodecylbenzenesulfonate are placed in the reactor together in a weight ratio of 1:4, and after the temperature in the reactor is raised to 80°C, under constant temperature conditions, the Add fulvic acid dropwise at a uniform rate, then add ammonia water dropwise at a constant rate, and add dropwise while stirring. After completion, add graphene to the reaction, continue stirring for 3 hours, and after high temperature and high pressure treatment for 60 seconds, quickly release the pressure to normal pressure, take out the mixture and pump Filter and dry to obtain material A for subsequent use;

[0058] b. Immerse the material A obtained in operation a into the modification solution, then place the ultrasonic probe at a position 3cm below the surface of the modification solution, perform ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com