Primary side feedback constant-current control system

A constant-current control, primary-side feedback technology, applied in the control/regulation system, converting DC power input to DC power output, AC power input converting to DC power output, etc. High cost and other problems, to achieve the effect of reducing power supply development cost, simple control implementation method, and high constant current output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

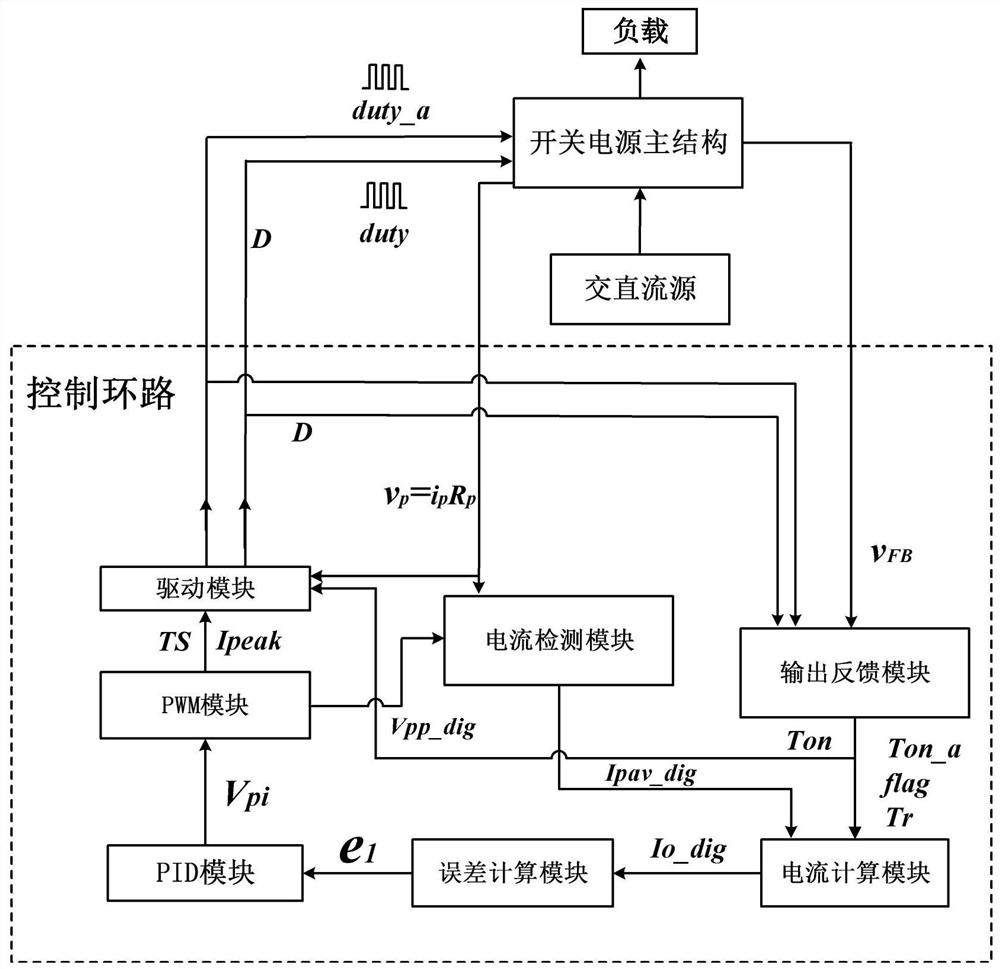

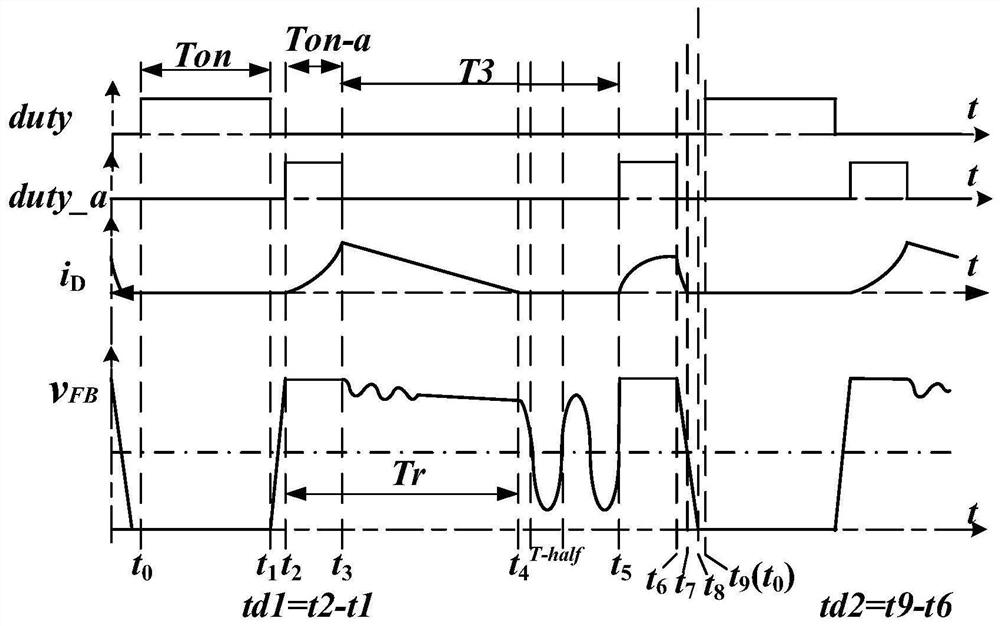

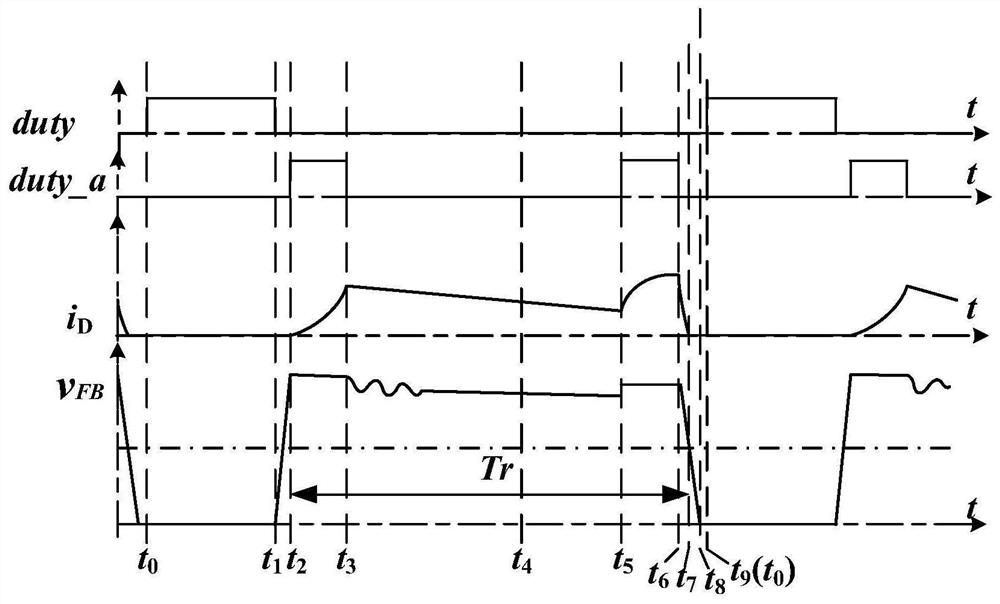

[0041] Such as figure 1 As shown, a primary-side feedback constant current control system includes an output feedback module, a current detection module, a drive module, a current calculation module, an error calculation module, a PID module, and a PWM module. The output feedback module realizes parameter collection and Calculation, the output result is used for the calculation of the current module. The current calculation module performs calculations based on the parameters provided by the output feedback module and the current detection module. The obtained result enters the error calculation module, and compares the obtained result with the reference value. The PID module operation can obtain the peak value of the sampling voltage of the primary side. In the PWM module, the mode can be judged according to the peak value of the sampling voltage, and the next switching cycle Ts and the peak value of the primary side current can be obtained according to the corresponding mode....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com