Canned high-protein oil-immersed tuna and processing technology thereof

A processing technology and technology of tuna, which is applied in the field of food processing, can solve the problems of being unable to meet the eating needs of different consumers, reducing the quality of canned tuna in oil, and not carrying out deodorization treatment, so as to improve the taste and flavor, increase appetite, stimulate Effects on the senses and taste buds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

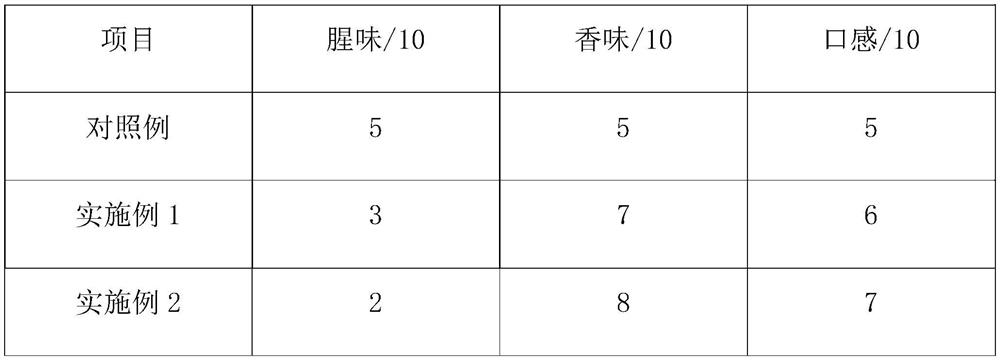

Embodiment 1

[0026] A high-protein oil-soaked canned tuna, the formula comprising: tuna meat, peanut kernels, walnut kernels, pea rice, sunflower seeds, refined vegetable oil, black sesame and refined salt, and the parts by weight of each component are: 80-90 parts Tuna meat, 12-16 parts of peanut kernels, 11-13 parts of walnut kernels, 8-10 parts of pea rice, 3-7 parts of sunflower seeds, 10-15 parts of refined vegetable oil, 6-10 parts of black Sesame and 2 to 4 portions of refined salt, refined vegetable oil selected from any one of soybean oil, rapeseed oil, palm oil, castor oil and coconut oil.

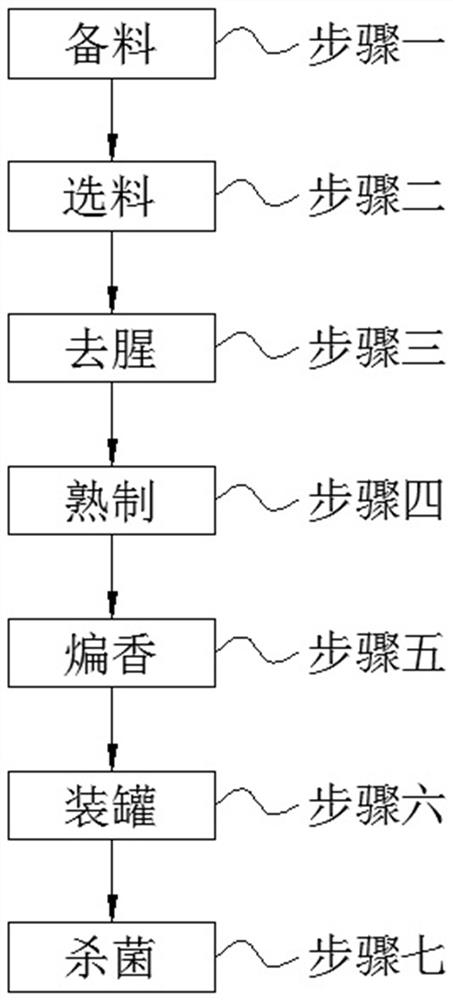

[0027] A high-protein oil-soaked canned tuna processing technology, comprising the following steps: Step 1, preparing ingredients; Step 2, selecting ingredients; Step 3, removing fishy smell; Step 4, cooking; Step 5, sautéing; Step 6, packing tank; step seven, sterilization;

[0028] Among them, in the above step 1, an appropriate amount of tuna is rinsed with clean water, and the head, tail...

Embodiment 2

[0036] A high-protein oil-soaked canned tuna, the formula comprising: tuna meat, peanut kernels, walnut kernels, pea rice, sunflower seeds, refined vegetable oil, black sesame and refined salt, and the parts by weight of each component are: 80-90 parts Tuna meat, 12-16 parts of peanut kernels, 11-13 parts of walnut kernels, 8-10 parts of pea rice, 3-7 parts of sunflower seeds, 10-15 parts of refined vegetable oil, 6-10 parts of black Sesame and 2 to 4 portions of refined salt, refined vegetable oil selected from any one of soybean oil, rapeseed oil, palm oil, castor oil and coconut oil.

[0037]A high-protein oil-soaked canned tuna processing technology, comprising the following steps: Step 1, preparing ingredients; Step 2, selecting ingredients; Step 3, removing fishy smell; Step 4, cooking; Step 5, sautéing; Step 6, packing tank; step seven, sterilization;

[0038] Among them, in the above step 1, an appropriate amount of tuna is rinsed with clean water, and the head, tail ...

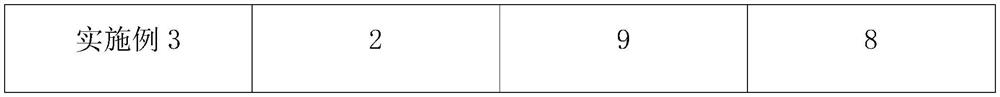

Embodiment 3

[0046] A high-protein oil-soaked canned tuna, the formula comprising: tuna meat, peanut kernels, walnut kernels, pea rice, sunflower seeds, refined vegetable oil, black sesame and refined salt, and the parts by weight of each component are: 80-90 parts Tuna meat, 12-16 parts of peanut kernels, 11-13 parts of walnut kernels, 8-10 parts of pea rice, 3-7 parts of sunflower seeds, 10-15 parts of refined vegetable oil, 6-10 parts of black Sesame and 2 to 4 portions of refined salt, refined vegetable oil selected from any one of soybean oil, rapeseed oil, palm oil, castor oil and coconut oil.

[0047] A high-protein oil-soaked canned tuna processing technology, comprising the following steps: Step 1, preparing ingredients; Step 2, selecting ingredients; Step 3, removing fishy smell; Step 4, cooking; Step 5, sautéing; Step 6, packing tank; step seven, sterilization;

[0048] Among them, in the above step 1, an appropriate amount of tuna is rinsed with clean water, and the head, tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com