Process treatment method for improving stability of terbutaline sulphate solution for nebulization

A technology of terbutaline sulfate and treatment method, which is applied in the field of medicine, can solve the problems of high production operation requirements and high production costs, and achieve the effects of low requirements, ensuring stability and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

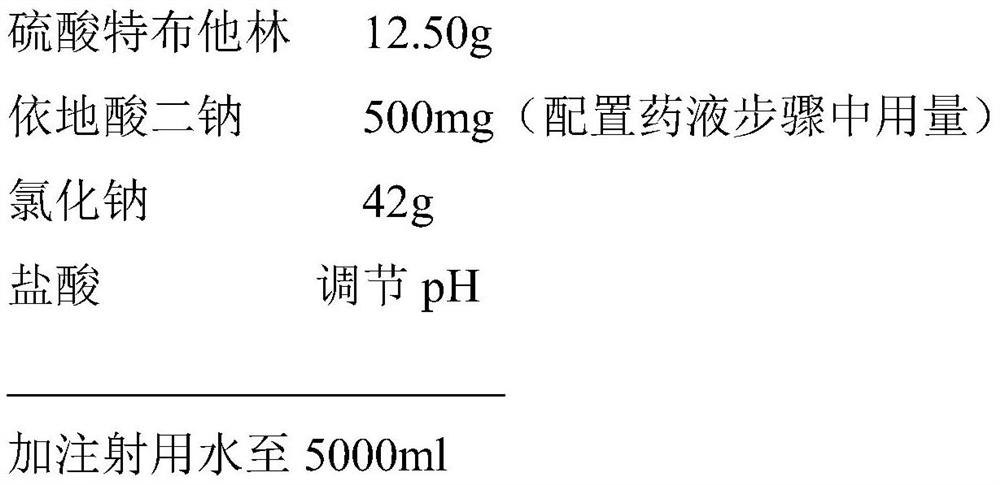

[0044] prescription:

[0045]

[0046] A process for improving the stability of terbutaline sulfate atomized liquid is as follows:

[0047] 1. Clean the equipment until the pH of the cleaning water is 6.0-8.0

[0048] 2. Weigh edetate disodium, add water for injection at 25°C to prepare 0.02% edetate disodium solution, use this solution to passivate the production equipment on the production line, passivation time 1h, passivation temperature 25°C .

[0049] 3. Take 30% of the prescribed amount of water for injection and add it to the passivated liquid mixing tank at 40°C, put in edetate disodium and stir to dissolve, then put in terbutaline sulfate and sodium chloride, and add water for injection to the batch size 80%, after stirring and dissolving, add 0.1mol / L hydrochloric acid solution to adjust the pH to 3.0-4.5, and add water for injection to the full batch.

[0050] 4. The liquid medicine is filtered through a 0.45μm filter and a 0.22μm bacteria-reducing filter.

...

Embodiment 2

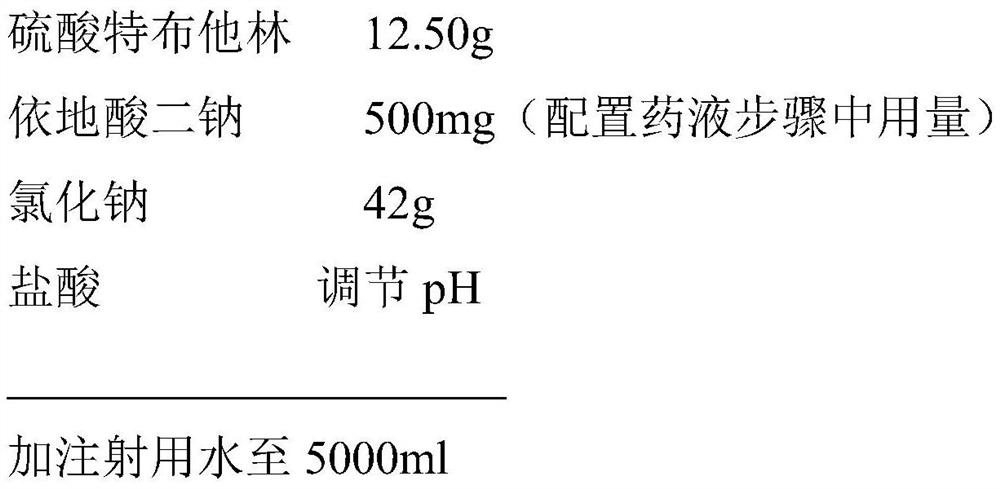

[0053] prescription:

[0054]

[0055] A process for improving the stability of terbutaline sulfate atomized liquid is as follows:

[0056]1. Weigh edetate disodium, add 70°C for injection to prepare 0.04% edetate disodium solution, use this solution to passivate the production equipment on the production line, the passivation time is 2h, and the passivation temperature is 70°C . After passivation, clean the equipment until the pH of the cleaning water is 6.0-8.0.

[0057] 2. Take 30% of the prescribed amount of water for injection and add it to the passivated liquid mixing tank at 40°C, put in edetate disodium and stir to dissolve, then put in terbutaline sulfate and sodium chloride, and add water for injection to the batch size 80%, after stirring and dissolving, add 0.1mol / L hydrochloric acid solution to adjust the pH to 3.0-4.5, and add water for injection to the full batch.

[0058] 3. The liquid medicine is filtered through a 0.45μm filter and a 0.22μm bacteria-red...

Embodiment 3

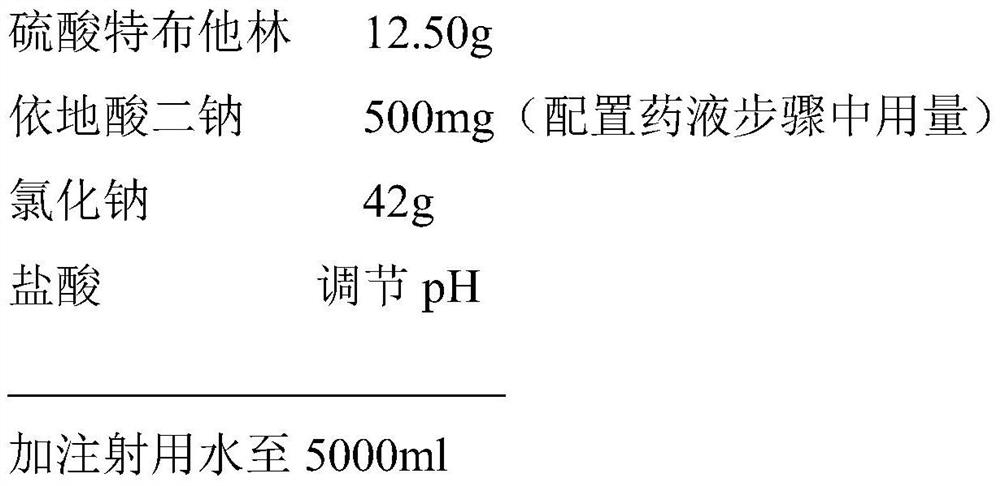

[0061] prescription:

[0062]

[0063] A process for improving the stability of terbutaline sulfate atomized liquid is as follows:

[0064] 1. Wash the production equipment with 4% sodium hydroxide solution for 1 hour, and wash with water for injection until the pH of the cleaning water is 6.0-8.0; then wash the equipment with 11% citric acid solution for 2 hours, and wash with water for injection until the pH of the cleaning water is 6.0-8.0.

[0065] 2. Weigh edetate disodium, add 70°C for injection to prepare 0.02% edetate disodium solution, use this solution to passivate the production equipment on the production line, passivation time 1h, passivation temperature 70°C . After passivation, clean the equipment until the pH of the cleaning water is 6.0-8.0.

[0066] 3. Take 30% of the prescribed amount of water for injection and add it to the passivated liquid mixing tank at 40°C, put in edetate disodium and stir to dissolve, then put in terbutaline sulfate and sodium ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com