Carbon steel corrugated pipe drawing machine

A tube drawing machine and corrugation technology, which is applied in the field of carbon steel corrugated tube drawing machines, can solve the problems of difficult processing, low processing efficiency, and low processing quality, so as to improve the processing efficiency and product quality, and reduce the deformation of the tube body. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-9 The application is described in further detail.

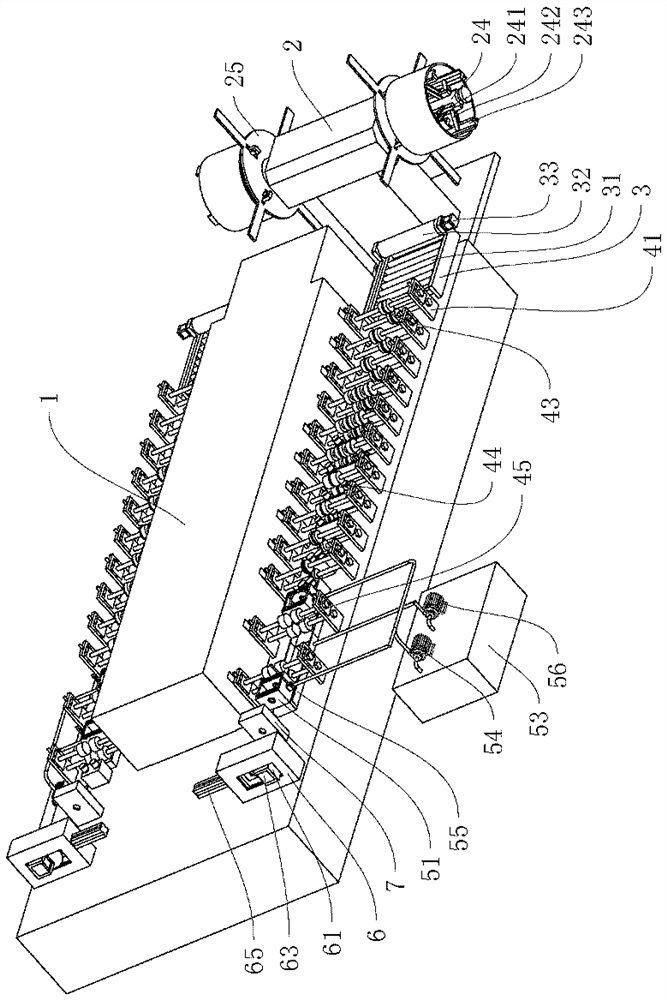

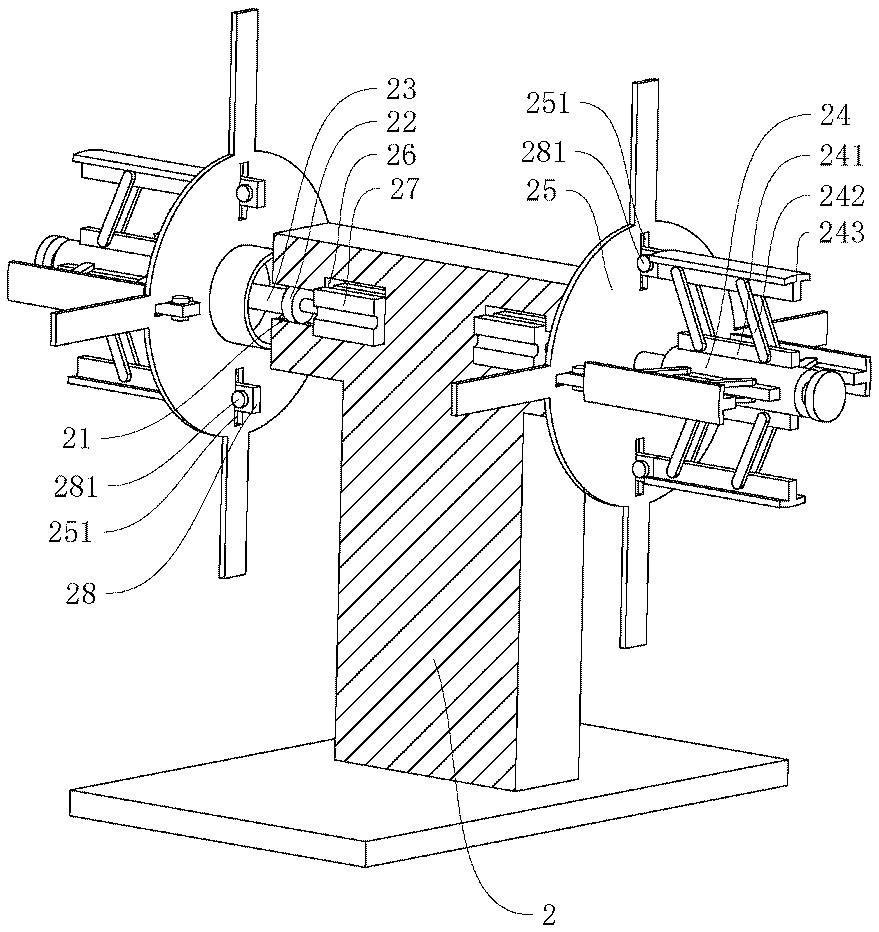

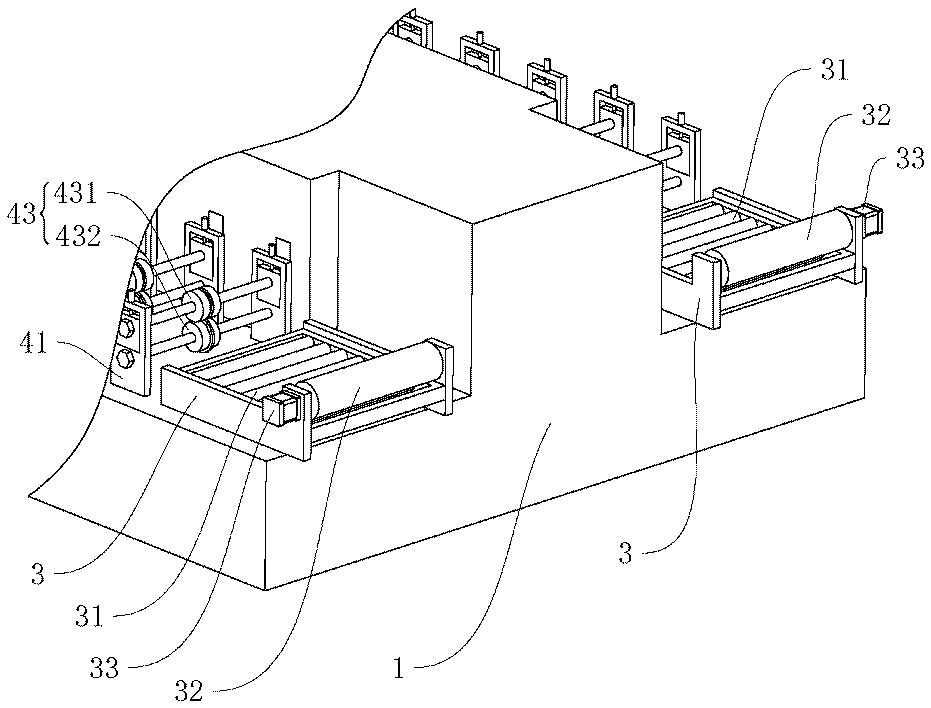

[0044] The embodiment of the present application discloses a carbon steel corrugated pipe drawing machine. refer to figure 1 , the pipe drawing machine includes a machine base 1, on which a production device is symmetrically fixed and installed, both of the two production devices can be used to effectively produce bellows products, and the production device includes placing in sequence according to the production and processing procedures Material mechanism, feeding mechanism, forming mechanism and cutting mechanism, these mechanisms carry out effective forming and processing on the thin sheet in turn to produce the required corrugated pipe products, which can facilitate the automatic processing of corrugated pipe products, and then can improve the corrugated pipe. The processing efficiency and product quality of tube products.

[0045] When it is necessary to make corrugated pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com