Laser 3D printing device for improving forming density and 3D printing method

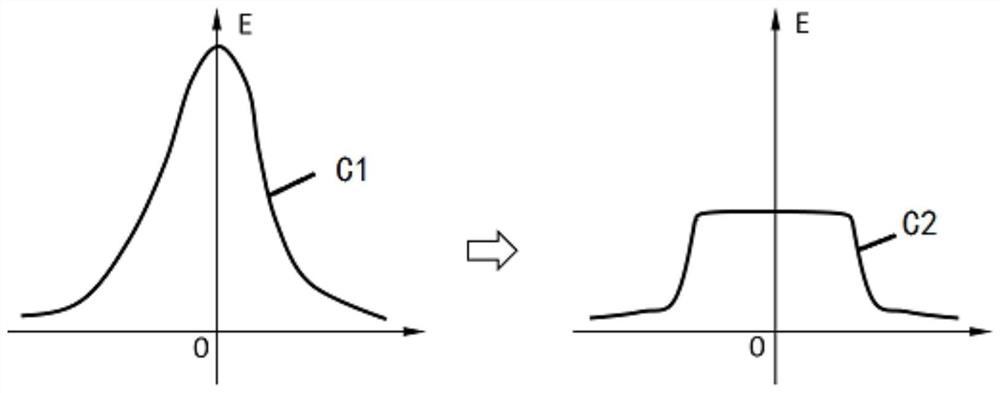

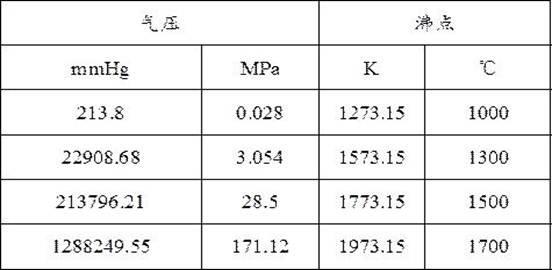

A 3D printing and dense technology, applied in the field of 3D printing, can solve the problems of low density, low surface tension and high vapor pressure of magnesium alloy bone implants, and achieve the goal of improving the forming quality, density and boiling point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The present invention will be described in more detail below in conjunction with the schematic diagrams, which show preferred embodiments of the present invention. It should be understood that those skilled in the art can modify the present invention described here and still achieve the advantageous effects of the present invention. Therefore, the following description should be understood to be widely known to those skilled in the art, and not as a limitation to the present invention.

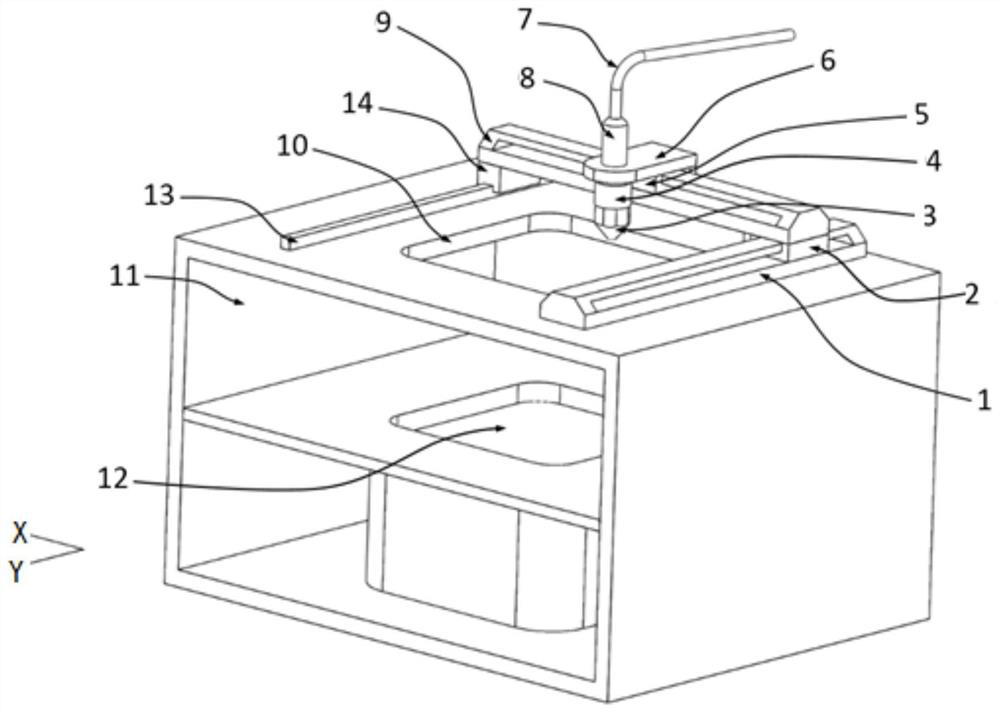

[0037]Such asfigure 1 As shown, a laser 3D printing device for improving forming density includes: forming bin 11, Y-axis linear motor 1, Y-axis guide rail 13, X-axis linear motor 9 and laser light emitting system; the laser light emitting system includes optical fibers connected in sequence 7. Collimator 8, beam expander 4 and flat top beam shaper 3.

[0038]The forming chamber 11 is sealed and arranged; a forming cylinder 12 mechanism is arranged in the forming chamber 11; a laser transparent wind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com