Low-smoke environment-friendly comprehensive groove machining device

A comprehensive processing and fume technology, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, unstable quality of processing grooves, high temperature deformation of processing platforms and test plates, etc., to reduce labor intensity. , Improve the efficiency of break processing and improve the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with examples.

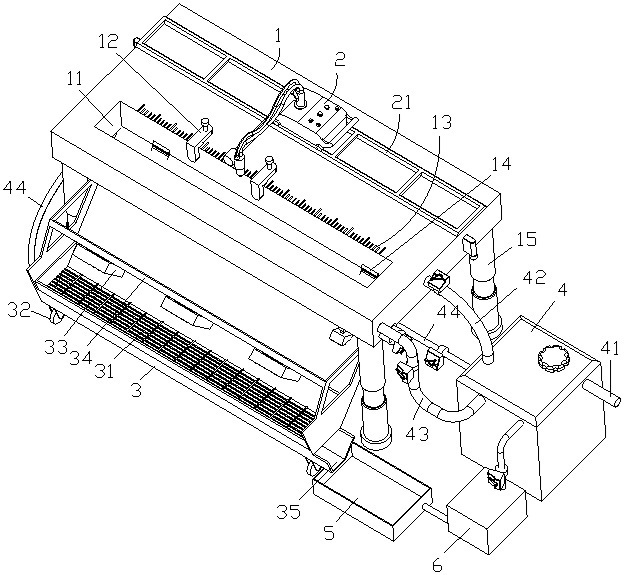

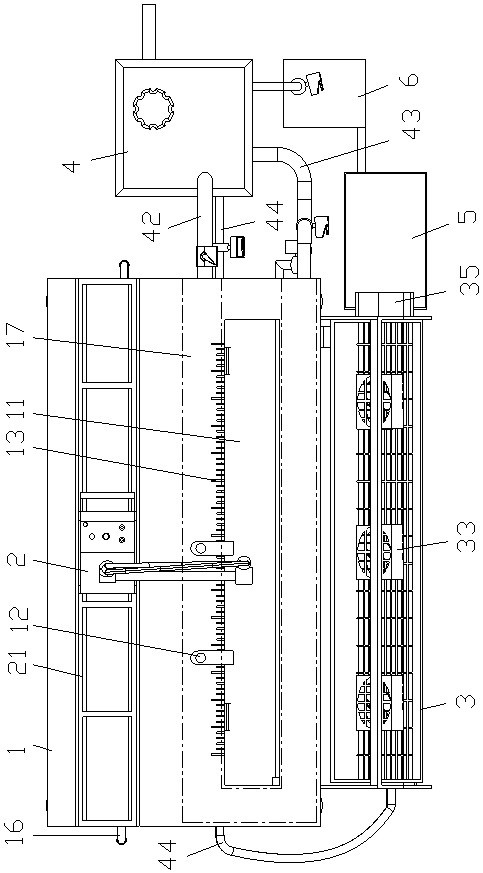

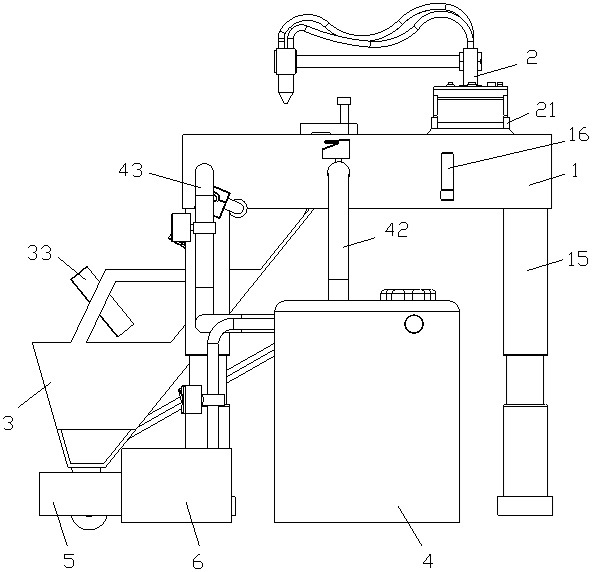

[0035] Such as figure 1 , 2 , 3, 4, a comprehensive processing device for low-smoke and environmental protection beveling, including:

[0036] Such as figure 1 , 2 Shown, the operation platform 1 of stainless steel rectangle, the table top of described operation platform 1 is provided with strip hole 11, as the stainless steel test plate bevel processing station; Image 6 , 7 As shown, there is also a circulating water channel 17 inside the table top of the operating platform 1 , and the circulating water channel 17 is arranged around the strip hole 11 . The strip-shaped hole 11 is used for slag removal and cooling to facilitate cutting of the test piece, and the inside of the circulating water channel 17 is filled with circulating water to cool and insulate the strip-shaped hole 11 to control deformat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com