Waterproof breathable component and waterproof shell

A technology of waterproof, breathable and waterproof casing, which is applied in the direction of synthetic resin layered products, chemical instruments and methods, and layered products. It can solve the problems of not reaching IPX5 or IPX6 waterproof level, poor waterproof performance, and test failure. Good adhesion, reduced deformation, and not easy to disengage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

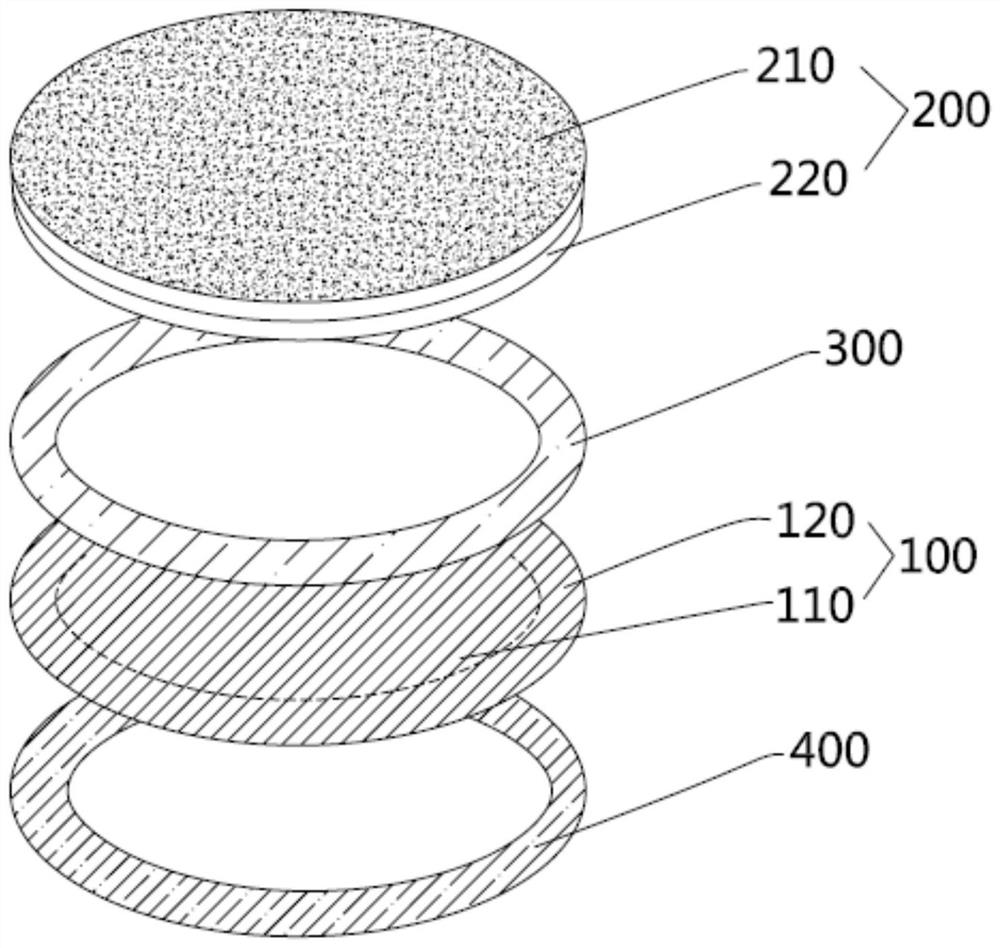

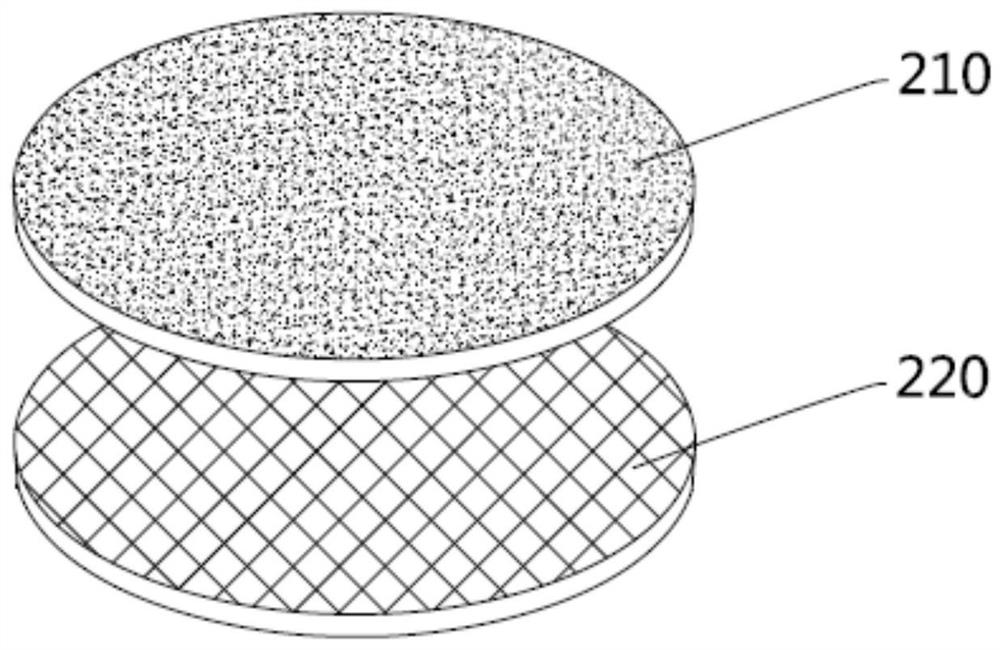

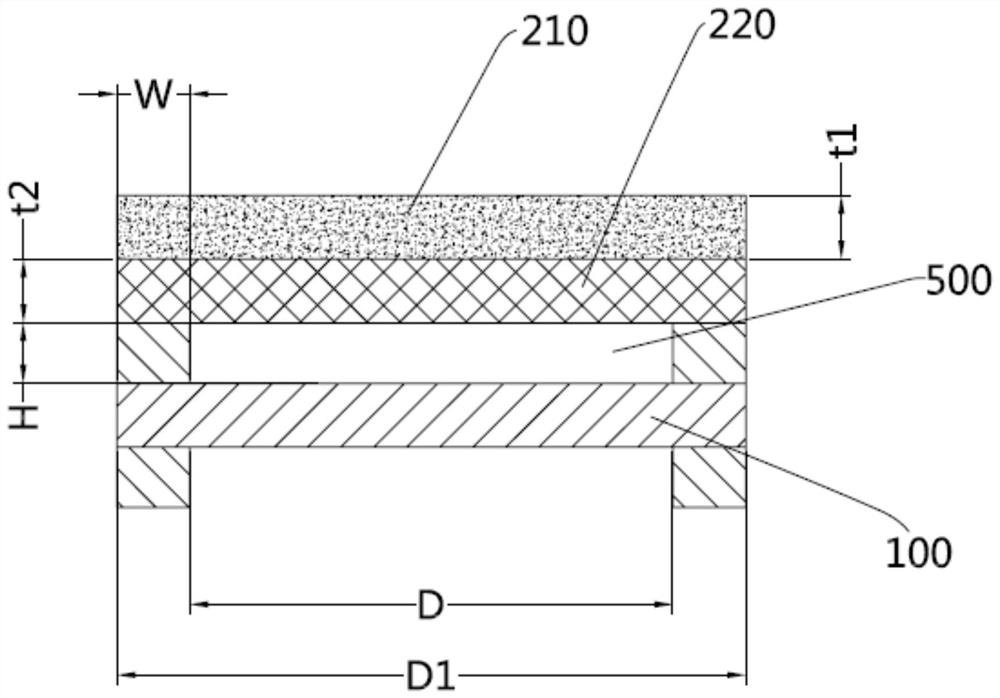

[0042] refer to Figures 1 to 3 As shown, the waterproof and breathable member in this embodiment includes the first PTFE membrane 100 facing the incoming water side and the PTFE composite membrane 200 facing away from the incoming water side. Adhesive portion 120, PTFE composite membrane 200 comprises base material 210 and the second PTFE membrane 220 that is arranged on the base material 210, base material 210 is arranged on the water side away from, the second PTFE membrane 220 and one side of the first PTFE membrane 100 There is a first adhesive layer 300 bonded to the adhesive portion 120 between them, and the other side of the first PTFE membrane 100 is provided with a second adhesive layer 400 bonded to the adhesive portion 120, the first adhesive layer 300 and the second adhesive layer 400 The two adhesive layers 400 are both ring-shaped.

[0043] In this embodiment, when the waterproof and breathable member is tested for IPX5 or IPX6 waterproof level, since water fir...

Embodiment 2

[0053] Such as Figure 4 As shown, the present invention also provides a waterproof casing 600. The waterproof casing 600 is provided with a through hole 610 connecting the inner cavity of the casing and the outside world. The waterproof and breathable member described in Embodiment 1 is installed in the waterproof casing 600. The second adhesive layer 400 is bonded to the inner wall of the waterproof housing to cover the through hole 610 , wherein the inner diameter of the second adhesive layer 400 is larger than the diameter of the through hole 610 . In other embodiments, the second adhesive layer can also be bonded to the outer wall of the waterproof casing to cover the through hole, but compared with this fixing method, in this embodiment, the waterproof and breathable member is installed in the waterproof casing, which can ensure The appearance of the waterproof casing can also play a good role in protecting the waterproof and breathable components, preventing them from f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water pressure | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com