A kind of unburned red mud brick and its preparation method

A technology of unburned bricks and red mud, which is applied in the field of unburned bricks, can solve the problems of excessive radioactivity of red mud, excessive dissolution of heavy metals, and affecting human health, etc., achieve good early mechanical properties, improve hydration activity, and prevent moisture The effect of communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

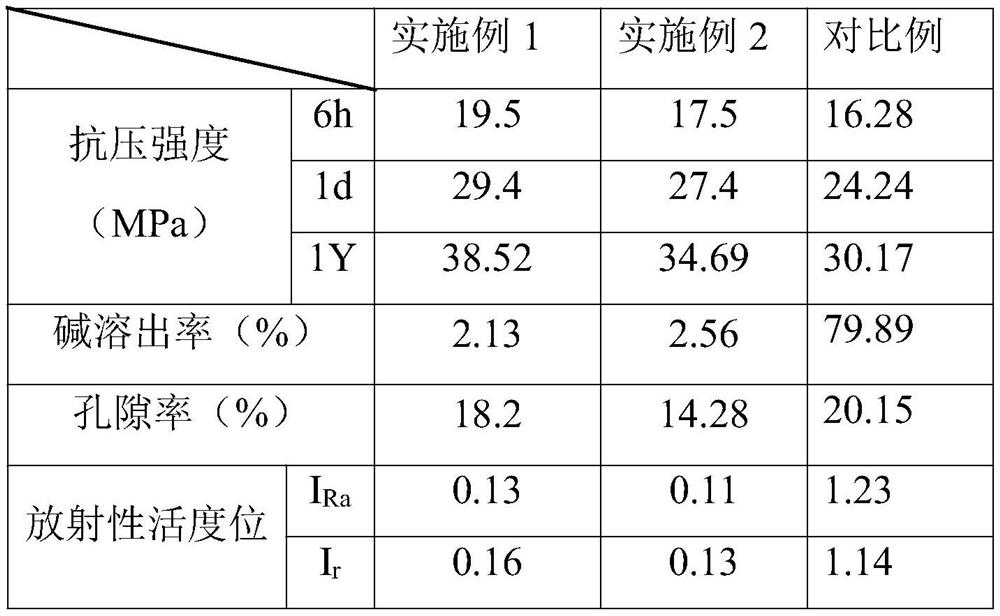

Examples

Embodiment 1

[0027] A red mud non-burning brick comprises, in terms of mass parts: 40 parts of red mud, 25 parts of sulphoaluminate cement clinker, 20 parts of steel slag, 10 parts of silica fume, and 10 parts of strontium slag.

[0028] A kind of preparation method of described red mud unburned brick, comprises the following steps:

[0029] S1. For the grinding treatment of sulfoaluminate cement clinker or aluminate cement clinker, it needs to be ground through a 200-mesh sieve, and steel slag and strontium slag do not need to be ground. Weigh 40 parts of red mud, 25 parts of sulphoaluminate cement clinker, 20 parts of steel slag, 10 parts of silica fume and 10 parts of strontium slag according to the above-mentioned parts by mass and mix them uniformly, then add 8% water to the mixture.

[0030] S2. The above-mentioned raw materials are pressed into shape under a pressure of 3 MPa, and cured in an environment with a humidity of 95% for 6 hours.

[0031] S3. Soak the cured burnt-free bri...

Embodiment 2

[0033] A red mud burn-free brick comprises, in terms of mass parts: 40 parts of red mud, 20 parts of aluminate cement mixed with 10% gypsum, 25 parts of steel slag, 15 parts of silica fume and 10 parts of strontium slag.

[0034] A kind of preparation method of described red mud unburned brick, comprises the following steps:

[0035] S1. For the grinding treatment of sulfoaluminate cement clinker or aluminate cement clinker, it needs to be ground through a 200-mesh sieve, and steel slag and strontium slag do not need to be ground. Weigh 40 parts of red mud, 25 parts of aluminate cement mixed with 5-15% gypsum, 20 parts of steel slag, 10 parts of silica fume, and 5 parts of strontium slag according to the above-mentioned parts by mass. After mixing evenly, add 5- 10% water.

[0036] S2. The above-mentioned raw materials are pressed into shape under a pressure of 7 MPa, and cured in an environment with a humidity of 85% for 3 hours.

[0037] S3. Soak the cured burnt-free brick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com