High-flame-retardant combined polyether for building floors

A combination of polyether and high flame-retardant technology, applied in the field of polyurethane foam, can solve the problems of heat resistance, hot-melt shrinkage, etc., and achieve the effect of strong adhesive strength, short curing period, and reduced building thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

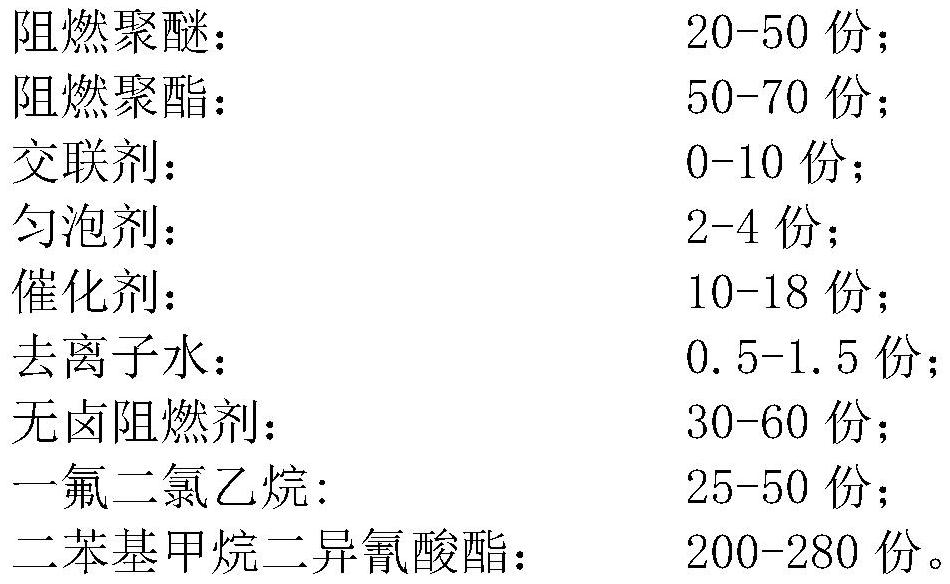

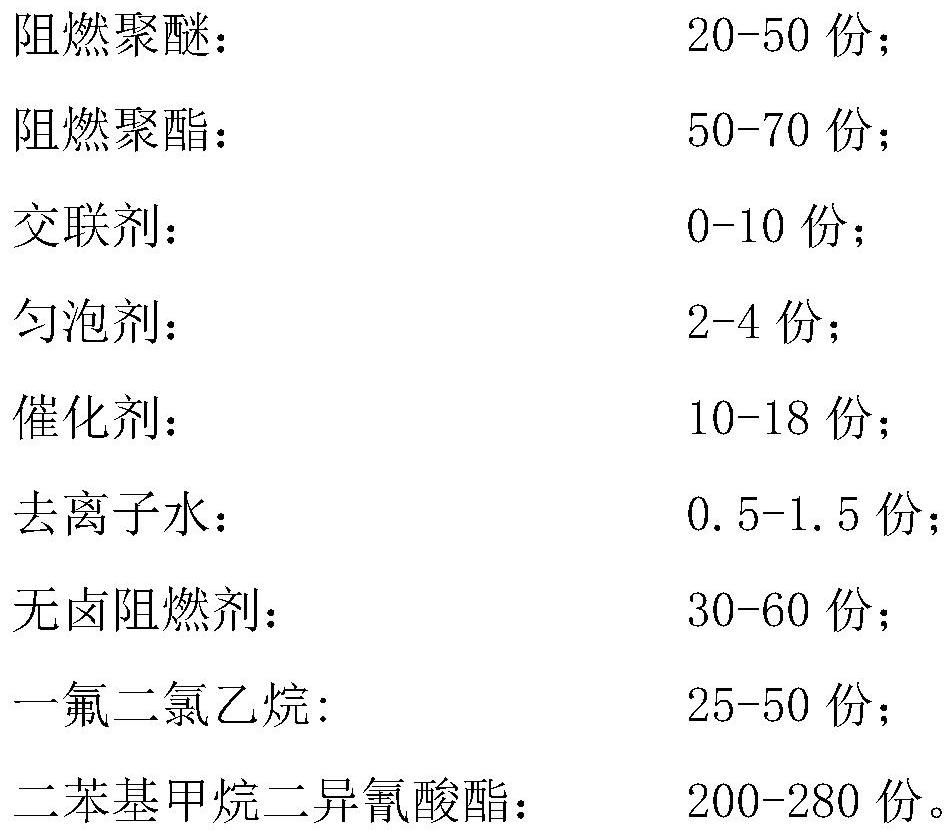

[0023] Example 1: A high flame-retardant composite polyether for flooring, including the following components:

[0024] Flame retardant polyether: 30 parts;

[0025] Flame-retardant polyester: 65 parts;

[0026] Cross-linking agent: 5 parts;

[0027] Foam stabilizer: 4 parts;

[0028] Catalyst: 13 parts;

[0029] Deionized water: 1 part;

[0030] Halogen-free flame retardant: 45 parts;

[0031] One fluorodichloroethane: 30 parts;

[0032] Diphenylmethane diisocyanate: 210 parts.

[0033] The catalyst is pentamethyldiethylenetriamine, organotin, triphenol, tris(dimethylaminopropyl)hexahydrotriazine, PT302 according to (0-10):(0-3):(0-10) :(0-10):(0-10) by compounding the mass ratio.

[0034] A kind of high flame retardant combined polyether used for floor surface was tested in the present embodiment, and the results are as follows:

[0035] Foam performance indicators:

[0036] Thermal conductivity: 0.022W / m.k

[0037] Water Absorption: 2%

[0038] Compressive stren...

Embodiment 2

[0040] Embodiment 2: A kind of highly flame-retardant combined polyether for flooring, including the following components:

[0041] Flame retardant polyether: 40 parts;

[0042] Flame-retardant polyester: 55 parts;

[0043] Cross-linking agent: 5 parts;

[0044] Foam stabilizer: 3 parts;

[0045] Catalyst: 12 parts;

[0046] Deionized water: 0.8 parts;

[0047] Halogen-free flame retardant: 40 parts;

[0048] One fluorodichloroethane: 33 parts;

[0049] Diphenylmethane diisocyanate: 205 parts.

[0050] The catalyst is pentamethyldiethylenetriamine, organotin, triphenol, tris(dimethylaminopropyl)hexahydrotriazine, PT302 according to (0-10):(0-3):(0-10) :(0-10):(0-10) by compounding the mass ratio.

[0051] A kind of high flame retardant combined polyether used for floor surface was tested in the present embodiment, and the results are as follows:

[0052] Foam performance indicators:

[0053] 1 Thermal conductivity: 0.021W / m.k

[0054] 2 Water absorption: 1.8%

[00...

Embodiment 3

[0057] Embodiment 3: A kind of highly flame-retardant combined polyether for flooring, including the following components:

[0058] Flame retardant polyether: 25 parts;

[0059] Flame-retardant polyester: 65 parts;

[0060] Cross-linking agent: 10 parts;

[0061] Foam stabilizer: 4 parts;

[0062] Catalyst: 14 parts;

[0063] Deionized water: 1.3 parts;

[0064] Halogen-free flame retardant: 50 parts;

[0065] One fluorodichloroethane: 2 parts;

[0066] Diphenylmethane diisocyanate: 230 parts.

[0067] The catalyst is pentamethyldiethylenetriamine, organotin, triphenol, tris(dimethylaminopropyl)hexahydrotriazine, PT302 according to (0-10):(0-3):(0-10) :(0-10):(0-10) by compounding the mass ratio.

[0068] A kind of high flame retardant combined polyether used for floor surface was tested in the present embodiment, and the results are as follows:

[0069] Foam performance indicators:

[0070] Thermal conductivity: 0.024W / m.k

[0071] Water Absorption: 2.5%

[0072] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com