A kind of polypropylene composite material with excellent water resistance and its preparation method and application

A polypropylene and water resistance technology, applied in the field of polypropylene composite materials and their preparation, can solve problems such as reduced water resistance, and achieve the effects of improving compatibility, facilitating diffusion, and improving water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

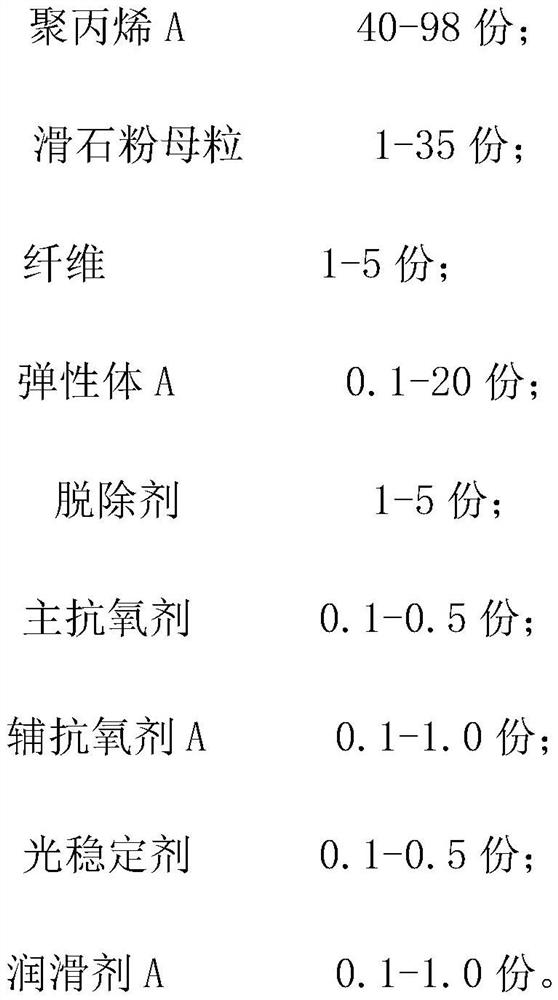

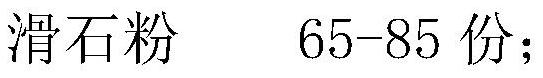

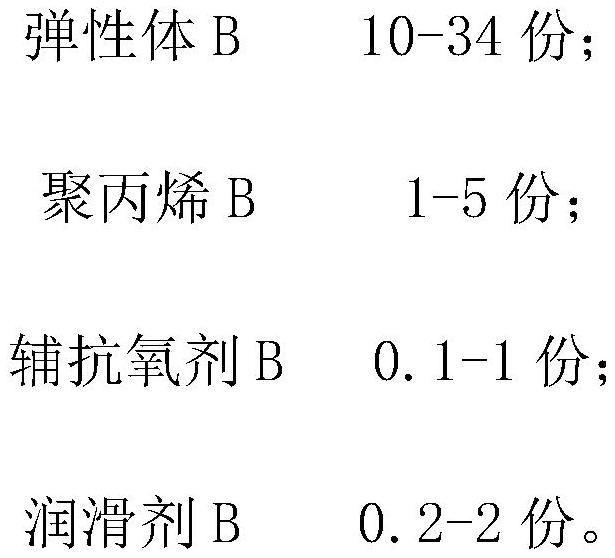

Image

Examples

Embodiment 1

[0045]A kind of polypropylene composite material with excellent water resistance, its raw material formula is shown in Table 2, and its preparation method includes the following steps: (1) mixing talc, elastomer B, auxiliary antioxidant B, lubricant B, polypropylene B Add it to an internal mixer or other meshing equipment and mix evenly, and then granulate to obtain talc masterbatch; (2) pulverize the PET-based hollow fiber to 150-325 mesh with a fiber shear mill, add it to the remover and mix evenly , to obtain the fiber mixture of the removing agent; (3) adding polypropylene A, elastomer A, main antioxidant, auxiliary antioxidant A, light stabilizer, and lubricant A into the high mixer for mixing, and then adding to In the twin-screw extruder, the talc masterbatch obtained in step (1) is separately added to the twin-screw extruder, and the above-mentioned materials are all added from the main feeding port of the twin-screw extruder. Step (2) The fiber mixture of the remover ...

Embodiment 2

[0049] A kind of polypropylene composite material with excellent water resistance, its raw material formula is shown in Table 2, and its preparation method includes the following steps: (1) mixing talc, elastomer B, auxiliary antioxidant B, lubricant B, polypropylene B Add it to an internal mixer or other meshing equipment and mix evenly, and then granulate to obtain talc masterbatch; (2) pulverize the PET-based hollow fiber to 150-325 mesh with a fiber shear mill, add it to the remover and mix evenly , to obtain the fiber mixture of the removing agent; (3) adding polypropylene A, elastomer A, main antioxidant, auxiliary antioxidant A, light stabilizer, and lubricant A into the high mixer for mixing, and then adding to In the twin-screw extruder, the talc masterbatch obtained in step (1) is separately added to the twin-screw extruder, and the above-mentioned materials are all added from the main feeding port of the twin-screw extruder. Step (2) The fiber mixture of the remover...

Embodiment 3

[0053] A kind of polypropylene composite material with excellent water resistance, its raw material formula is shown in Table 2, and its preparation method includes the following steps: (1) mixing talc, elastomer B, auxiliary antioxidant B, lubricant B, polypropylene B Add it to an internal mixer or other meshing equipment and mix evenly, and then granulate to obtain talc masterbatch; (2) pulverize the PET-based hollow fiber to 150-325 mesh with a fiber shear mill, add it to the remover and mix evenly , to obtain the fiber mixture of the removing agent; (3) adding polypropylene A, elastomer A, main antioxidant, auxiliary antioxidant A, light stabilizer, and lubricant A into the high mixer for mixing, and then adding to In the twin-screw extruder, the talc masterbatch obtained in step (1) is separately added to the twin-screw extruder, and the above-mentioned materials are all added from the main feeding port of the twin-screw extruder. Step (2) The fiber mixture of the remover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com