Polyester fiber fabric and preparation method thereof

A polyester fiber and fabric technology, applied in the field of fabric processing, can solve the problems of strength, dyeability short board, polyester fiber does not have antibacterial, health care performance, etc., to achieve easy promotion and application, strong market competitiveness, and standardized processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A polyester fiber fabric is prepared by weaving, dyeing and finishing composite fibers obtained by blending modified polyester fibers and natural fibers.

[0029] The natural fiber is wool fiber; the mass ratio of the modified polyester fiber to the natural fiber is 1:2.

[0030] The preparation method of described modified polyester fiber comprises the steps:

[0031] In the preparation process of the polyester chip, the modified filler component is added to the raw material, and then the conventional melt spinning and stretching treatment can be performed on the obtained polyester chip.

[0032] The added amount of the modified filler is 6% of the total mass of the polyester chip raw material.

[0033] The melting temperature is controlled at 330° C., and the spinning speed is controlled at 2000 m / min.

[0034] The preparation method of described modified filler comprises the steps:

[0035] 1) Carry out steam explosion treatment on the crop straw, take it out, imm...

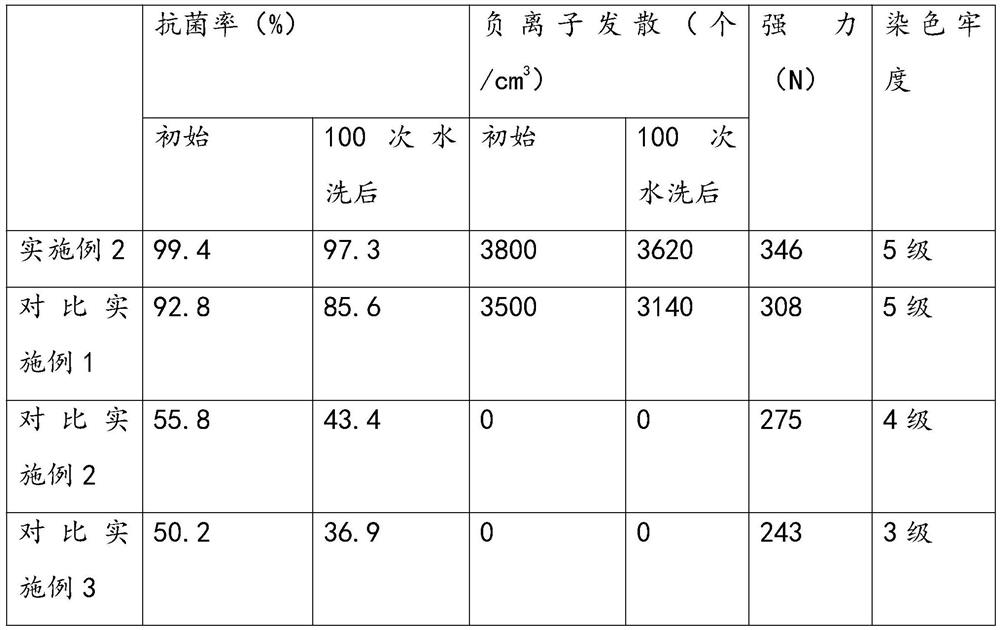

Embodiment 2

[0046] A polyester fiber fabric is prepared by weaving, dyeing and finishing composite fibers obtained by blending modified polyester fibers and natural fibers.

[0047] The natural fiber is silk fiber; the mass ratio of the modified polyester fiber to the natural fiber is 1:2.5.

[0048] The preparation method of described modified polyester fiber comprises the steps:

[0049] In the preparation process of the polyester chip, the modified filler component is added to the raw material, and then the conventional melt spinning and stretching treatment can be performed on the obtained polyester chip.

[0050] The added amount of the modified filler is 8% of the total mass of the polyester chip raw material.

[0051] The melting temperature is controlled at 335° C., and the spinning speed is controlled at 2050 m / min.

[0052] The preparation method of described modified filler comprises the steps:

[0053] 1) Carry out steam explosion treatment on the crop straw, take it out, i...

Embodiment 3

[0064] A polyester fiber fabric is prepared by weaving, dyeing and finishing composite fibers obtained by blending modified polyester fibers and natural fibers.

[0065] The natural fiber is cotton fiber; the mass ratio of the modified polyester fiber to the natural fiber is 1:3.

[0066] The preparation method of described modified polyester fiber comprises the steps:

[0067] In the preparation process of the polyester chip, the modified filler component is added to the raw material, and then the conventional melt spinning and stretching treatment can be performed on the obtained polyester chip.

[0068] The added amount of the modified filler is 9% of the total mass of the polyester chip raw material.

[0069] The melting temperature is controlled at 340° C., and the spinning speed is controlled at 2100 m / min.

[0070] The preparation method of described modified filler comprises the steps:

[0071] 1) Carry out steam explosion treatment on the crop straw, take it out, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com