A diesel engine with protective mechanism for agricultural machinery

A technology for protective mechanisms and agricultural machinery, applied to mechanisms that generate mechanical power, mechanical equipment, machines/engines, etc., can solve problems such as shortening the service life of diesel engines, achieve good heat dissipation effects, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

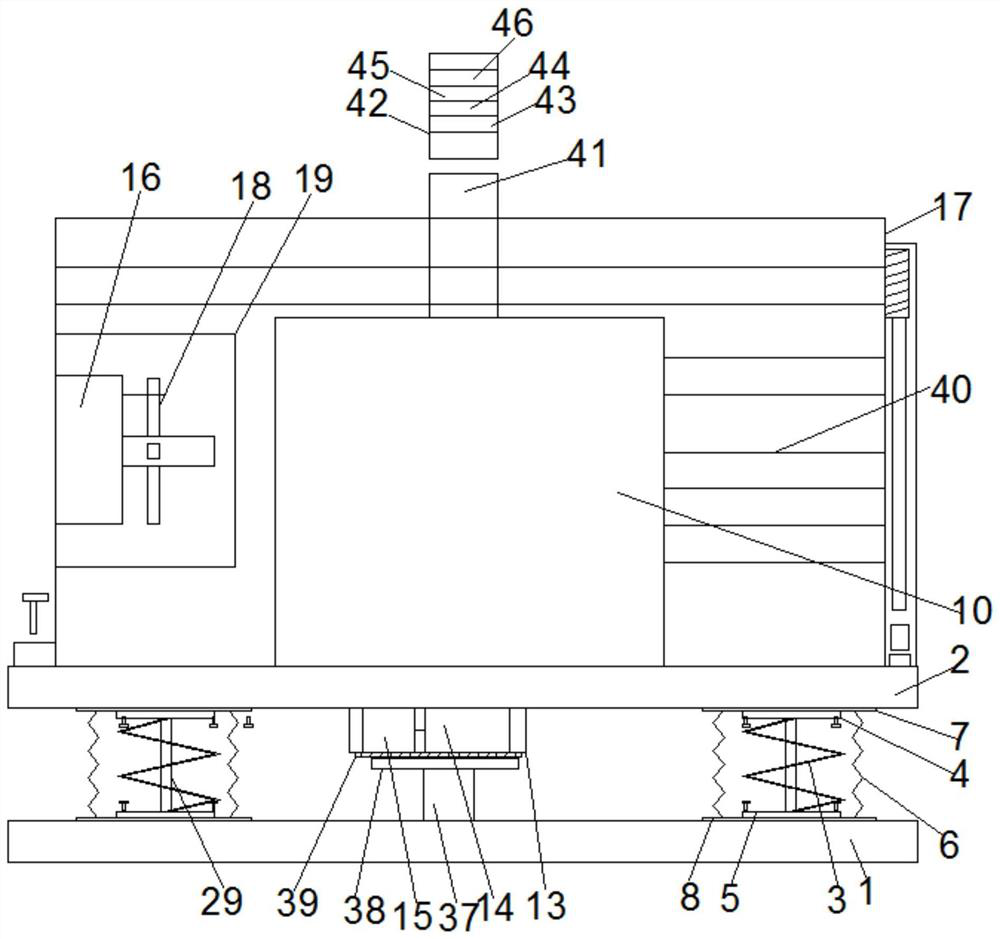

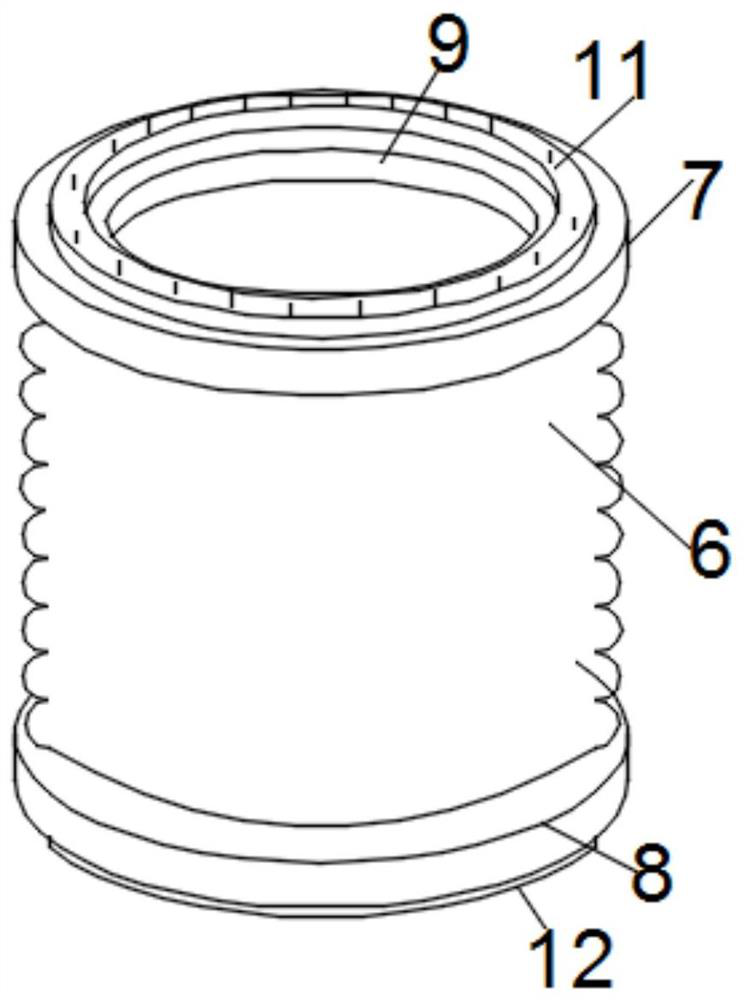

[0030] see Figure 1-5According to an embodiment of the present invention, a diesel engine with a protective mechanism for agricultural machinery includes a support plate 1, a sub-support plate 2 is provided on the top of the support plate 1, and a diesel engine 10 is placed on the top of the sub-support plate 2 , a damping mechanism is provided between the supporting plate 1 and the auxiliary supporting plate 2, the damping mechanism includes a spring 3, the top end of the spring 3 is fixedly provided with an upper threaded plate 4, and the bottom end of the spring 3 is fixed A lower threaded plate 5 is provided, the upper threaded plate 4 and the lower threaded plate 5 are respectively fixed on the support plate 1 and the auxiliary support plate 2 by screws, and the spring 3 is sleeved with a telescopic bellows 6. The top of the telescopic bellows 6 is fixed with an upper circular plate 7, the bottom of the telescopic bellows 6 is fixed with a lower circular plate 8, and bot...

Embodiment 2

[0032] see figure 1 , for the battery box 13, a box door is installed on the battery box 13, and the wires on the battery 14 pass through the auxiliary support plate 2 and extend to the inside of the protective cover 17 to connect with the motor 16 , the outer wall of the protective cover 17 is fixed with a mounting plate, and the mounting plate is fixed on the top of the auxiliary support plate 2 by screws.

Embodiment 3

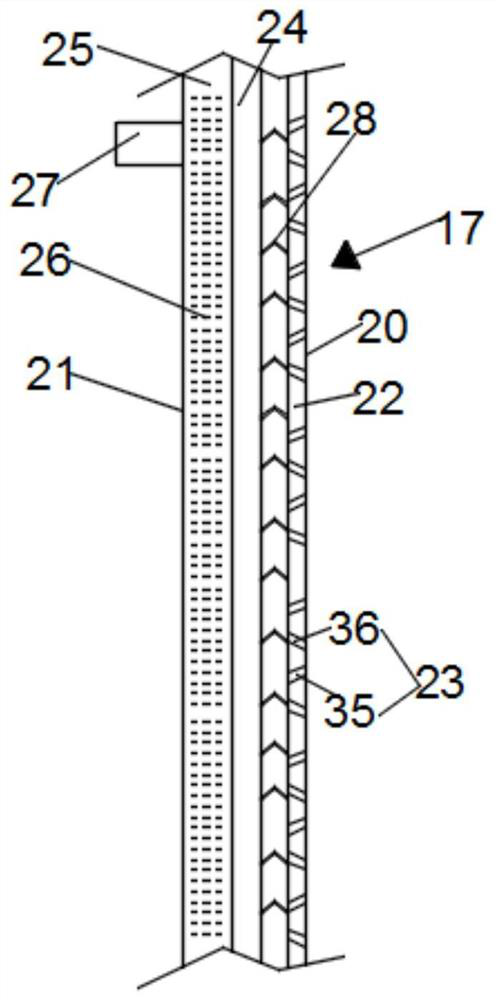

[0034] see figure 1 and Figure 4 , for the wind cover 19, the wind cover 19 is provided with a sound insulation mechanism, the sound insulation mechanism includes an inner cover 30 and an outer cover 31, and a sound absorption cavity 32 is formed between the inner cover 30 and the outer cover 31. The inner side of the inner cover 30 is fixed with a circular sound insulation board 33, the sound insulation board 33 is a honeycomb board, the inner side of the sound insulation board 33 is pasted with a sound-absorbing cotton layer 34, and the other side of the sound-absorbing cotton layer 34 is connected to the outer cover 31. internal fixed connection

[0035] Through the above scheme of the present invention, the beneficial effect is that the wind cover 19 is provided with a sound insulation mechanism, which can eliminate noise to a certain extent on the working noise generated during work, and can also eliminate noise from the motor 16 generated by the motor 16. The noise ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com