Oscillator type free electron laser three-hole coupling output method and device

A coupling output and oscillator technology, which is applied in the field of oscillator type free electron laser three-hole coupling output, can solve the problems of inability to carry out scientific experiments and serious influence, and achieves the improvement of free electron laser power, easy fabrication, and low fabrication cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The content not described in detail in the embodiments of the present invention belongs to the prior art known to those skilled in the art.

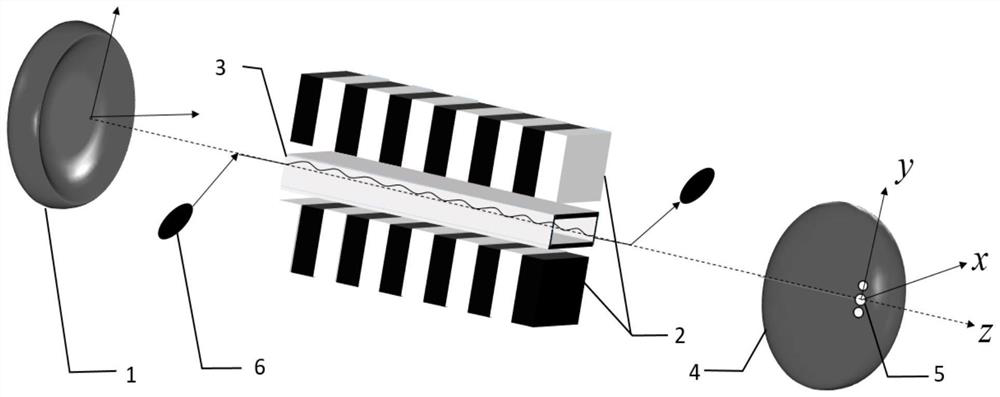

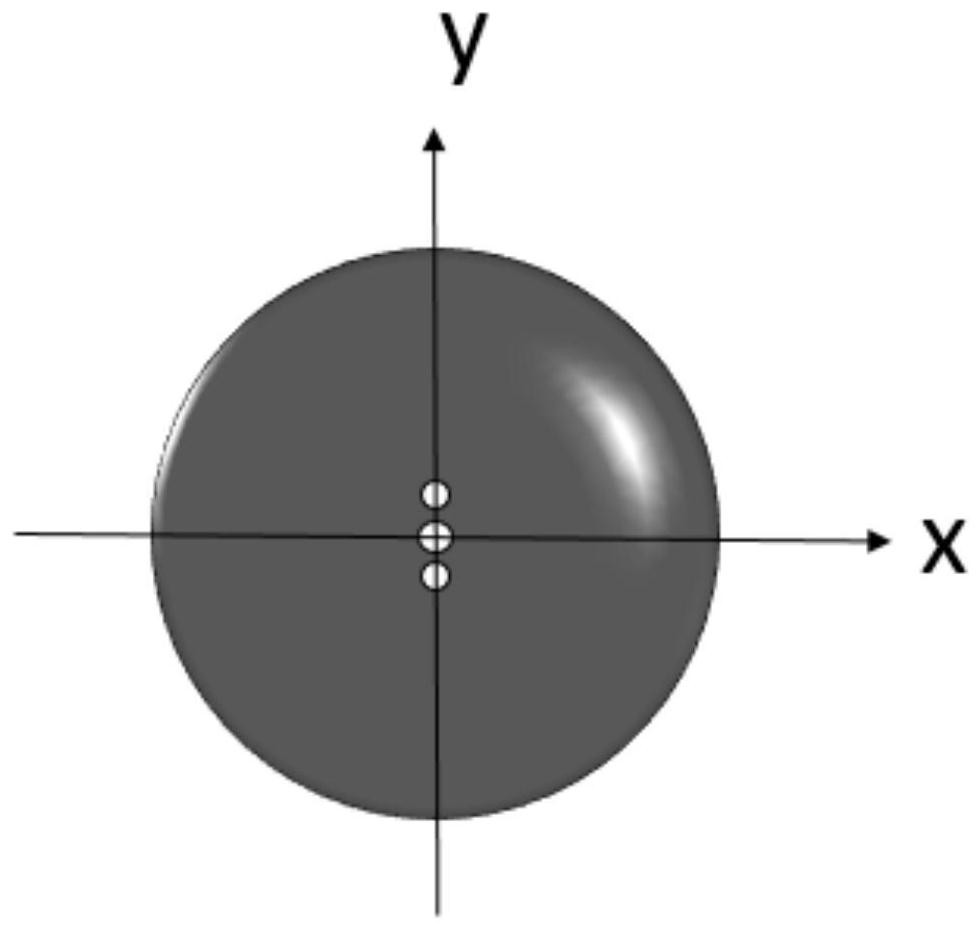

[0021] Such as figure 1 As shown, a kind of oscillator-type free electron laser three-hole coupling output device of the present invention comprises an upstream reflector 1, an undulator 2, an optical waveguide 3, a downstream reflector 4, a three-hole array 5 and an electron beam 6; The reflector 1 and the downstream reflector 4 are both placed in a high vacuum chamber and connected to the optical waveguide 3 through a vacuum pipe. The line between the centers of the two coincides with the line between the focal points to form an optical resonant cavity. The optical waveguide 3 is placed symmetrically on the at the center of the optical cavity. The upper and lower magnetic arrays of the undulator 2 are placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com