Preparation method and application of tobacco endogenous section material for heating cigarettes

A tobacco and endogenous technology, applied in the fields of application, tobacco, and tobacco preparation, to achieve the effects of reducing drying conditions, improving stability, and improving balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

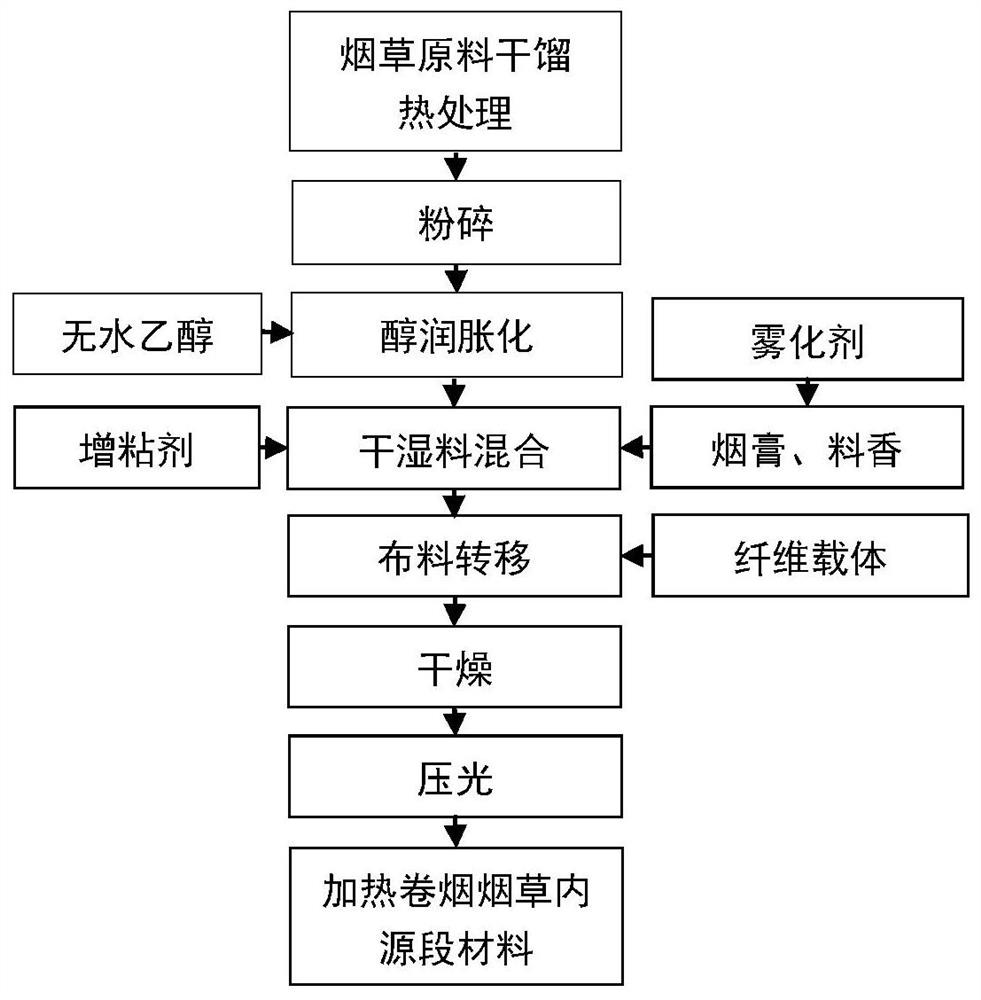

Method used

Image

Examples

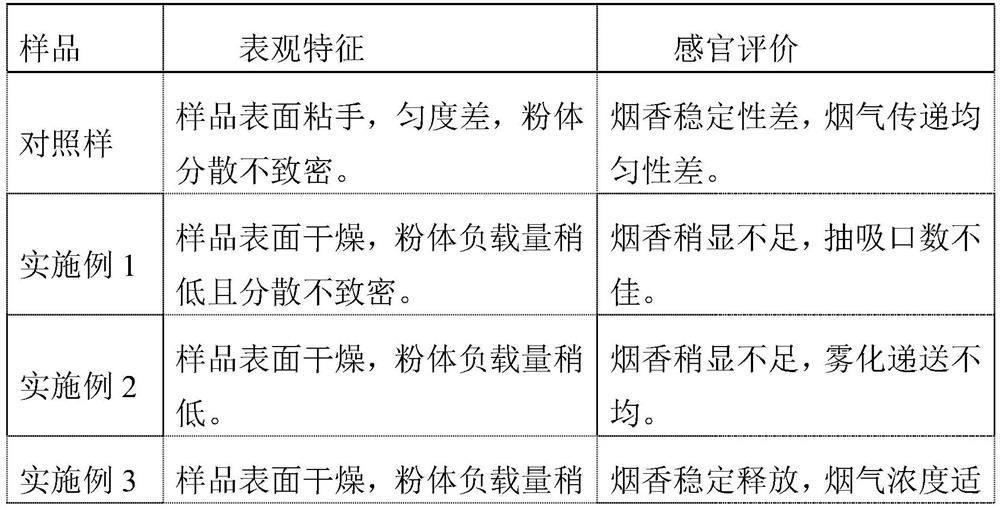

Embodiment 1

[0033] A preparation method suitable for heating cigarette tobacco endogenous material, comprising the following steps:

[0034] (1) Weigh the raw materials of flue-cured tobacco, sun-cured tobacco and oriental tobacco according to the mass ratio of 7.8:1.2:1.0 and mix them evenly, then undergo dry distillation heat treatment at 100-150°C, and then pulverize the heat-treated products to make a uniform particle size of 0.015-0.180mm Tobacco particles;

[0035] (2) Fully mix the absolute ethanol and the tobacco particles in the reactor, seal and let stand for 1 to 24 hours to obtain alcohol-swollen tobacco-based raw materials, the mass ratio of the tobacco particles to the absolute ethanol is 5.0:0.5;

[0036] (3) Use glycerin and propylene glycol as atomizers in a mass ratio of 7:3, heat and dissolve beeswax at 60-70°C, then add potassium malate solution dissolved in absolute ethanol, and polyvinyl alcohol and stir for 0.5-1.0 hours , carry out mutual emulsification reaction, ...

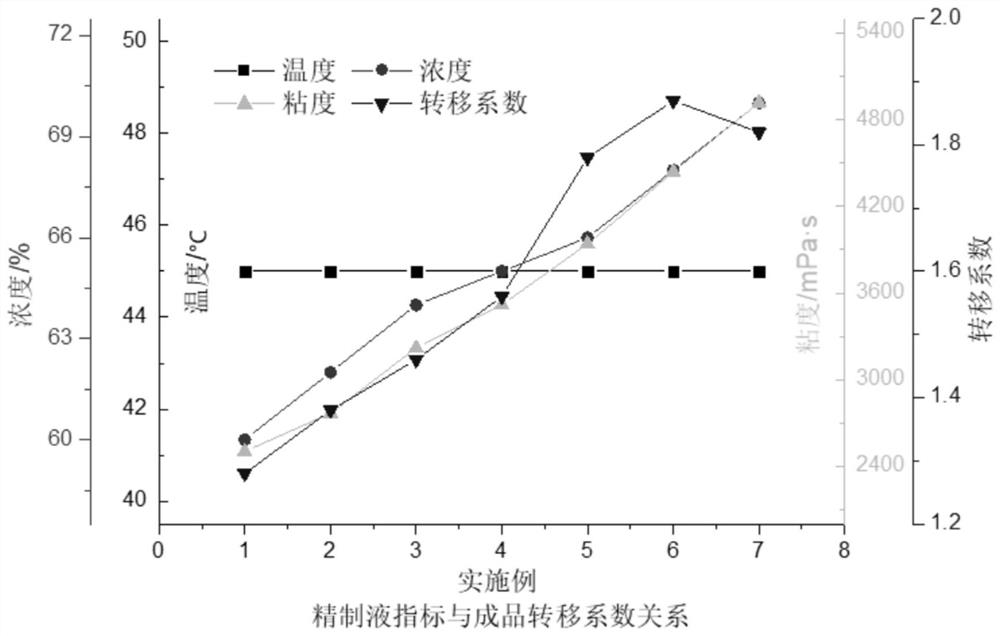

Embodiment 2~4

[0044] Same as Example 1, except that the amount of thickener and tobacco particles is different. The ratio is as follows:

Embodiment 2

[0046] Tackifier and mixed wet material mass ratio = 1.5:100.0

[0047] The mass ratio of tobacco particles to absolute ethanol=6.0:0.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com