Orderly edge cutting device for insulation boards

A side-cutting and heat-insulating board technology, which is applied in metal processing and other directions, can solve the problems of inaccurate cutting, loose fixing of foam boards, easy movement of foam boards, etc., and achieve the effect of accurate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

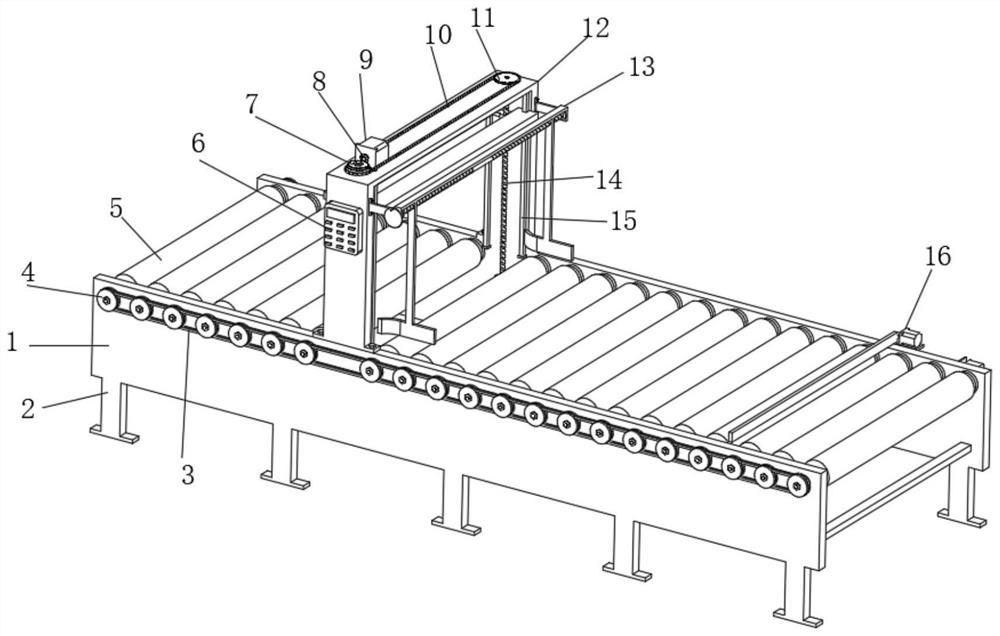

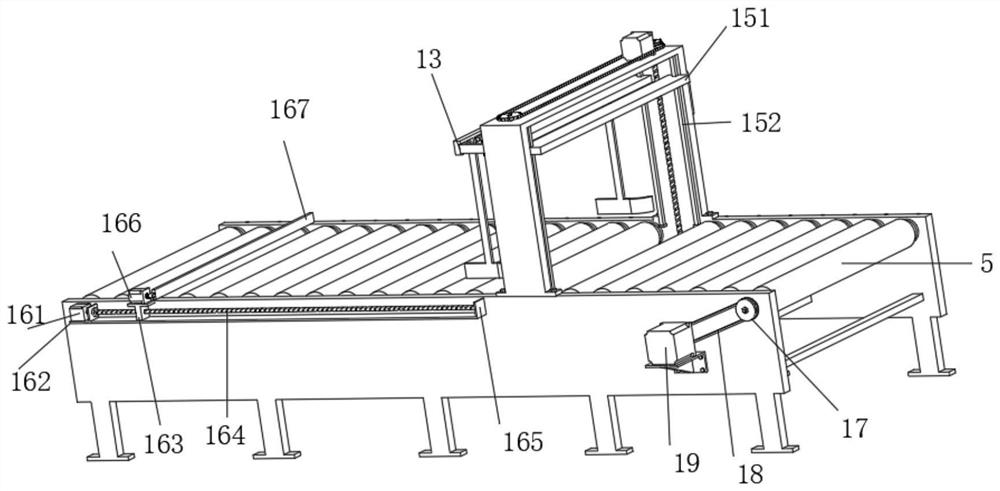

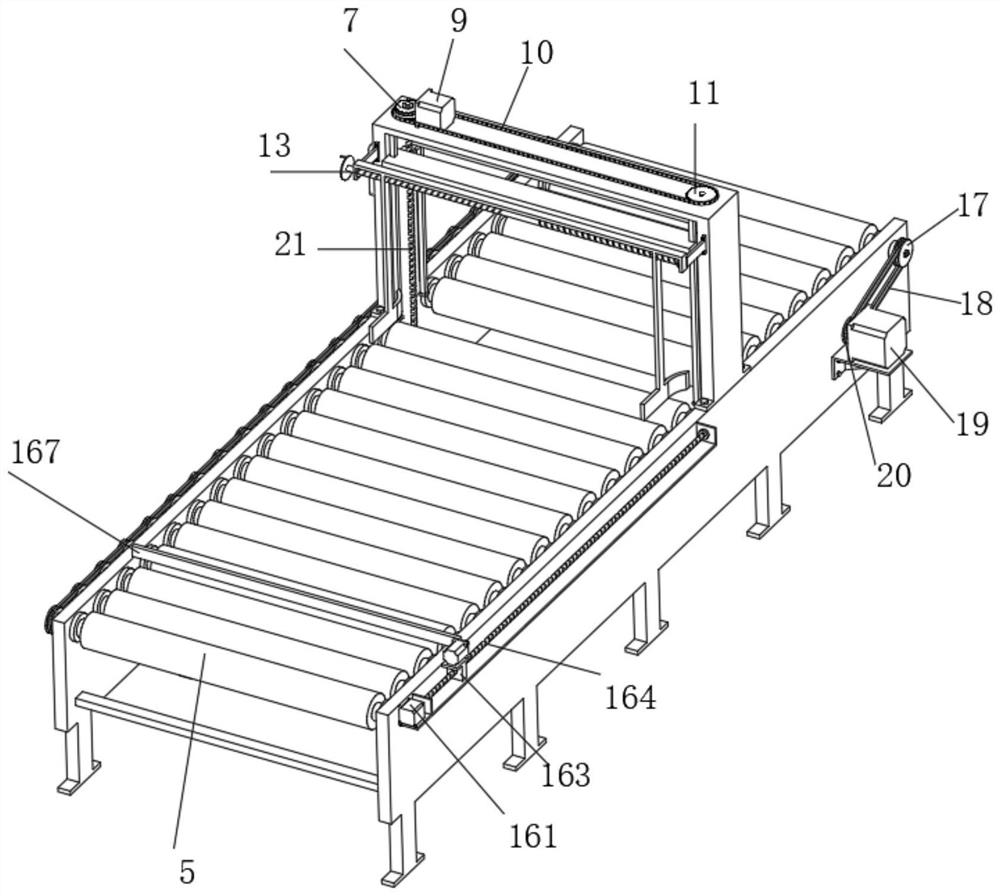

[0034] Such as Figure 1-6A thermal insulation board trimming cutting device is shown, comprising a support plate 1, a controller 6 and a fourth drive motor 19, the bottom of the support plate 1 is uniformly fixedly connected with legs 2 for support, and the inner wall of the support plate 1 is uniformly fixed The connected bearing is rotatably connected with a transmission roller 5, and the front end of the rotation shaft of the transmission roller 5 runs through the support plate 1 and is fixedly connected with the first pulley 4, and the first belt 3 is movably connected between the first pulleys 4, and the rotation shaft of a group of transmission rollers 5 The rear end runs through the support plate 1 and is fixedly connected with a second pulley 17, the second pulley 17 is movably connected with a second belt 18, the second belt 18 is movably connected with a third pulley 20, and the third pulley 20 is fixedly installed on the fourth driving motor 19 On the output end of...

Embodiment 2

[0036] Embodiment 2 is a further improvement to Embodiment 1.

[0037] Such as Figure 1-6 The edge-aligning cutting device for insulation boards shown includes a support plate 1, a controller 6 and a fourth drive motor 19. The bottom of the support plate 1 is uniformly fixedly connected with legs 2 for support, and the inner wall of the support plate 1 passes through a uniform The fixedly connected bearing is rotatably connected with the transmission roller 5, the front end of the rotating shaft of the transmission roller 5 runs through the support plate 1 and is fixedly connected with the first pulley 4, and the first belt 3 is movably connected between the first pulleys 4, and one group of transmission rollers 5 The rear end of the rotating shaft runs through the support plate 1 and is fixedly connected with a second pulley 17. The second pulley 17 is movably connected with a second belt 18. The second belt 18 is movably connected with a third pulley 20. The third pulley 20...

Embodiment 3

[0039] Embodiment 3 is a further improvement to Embodiment 1.

[0040] Such as Figure 1-6 The edge-aligning cutting device for insulation boards shown includes a support plate 1, a controller 6 and a fourth drive motor 19. The bottom of the support plate 1 is uniformly fixedly connected with legs 2 for support, and the inner wall of the support plate 1 passes through a uniform The fixedly connected bearing is rotatably connected with the transmission roller 5, the front end of the rotating shaft of the transmission roller 5 runs through the support plate 1 and is fixedly connected with the first pulley 4, and the first belt 3 is movably connected between the first pulleys 4, and one group of transmission rollers 5 The rear end of the rotating shaft runs through the support plate 1 and is fixedly connected with a second pulley 17. The second pulley 17 is movably connected with a second belt 18. The second belt 18 is movably connected with a third pulley 20. The third pulley 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com