Device and method for backwashing and inerting oil tank of military unmanned aerial vehicle by utilizing fuel oil

A technology of oil tanks and fuel tanks, which is applied to unmanned aircraft, fuel tank safety measures, motor vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

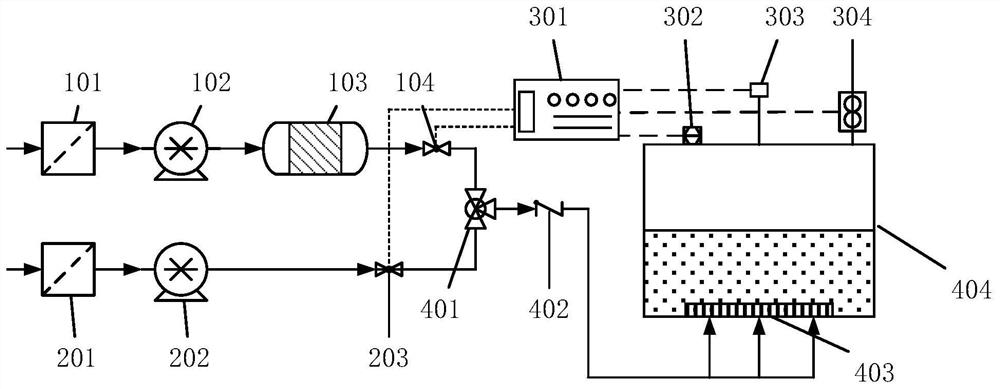

[0029] Such as figure 1 As shown, the present invention provides a kind of device that utilizes fuel backwashing inert military unmanned aerial vehicle oil tank, comprises the first air generation unit, hollow fiber membrane air separation module 103, the first solenoid valve 104, the second air generation unit, the first Two solenoid valves 203 and a mixing valve 401.

[0030] The first air generation unit, the hollow fiber membrane air separation module 103 and the first solenoid valve 104 are connected in sequence, and the air enters the hollow fiber membrane air separation module 103 for separation through the first air generation unit, and is separated into oxygen-enriched gas and nitrogen-enriched gas. The oxygen gas is exhausted to the atmosphere, and the nitrogen-enriched gas enters the first solenoid valve 104 .

[0031] The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com