Treatment method of industrial closed cooling water system

A technology of closed cooling water and treatment methods, which is applied in natural water treatment, non-polluted water treatment, neutralized water/sewage treatment, etc., and can solve problems such as small application system, unsuitable industrial application scenarios, and high cost of corrosion inhibitors , to achieve standard indicators and steps, stable and stable corrosion inhibition effect, and good corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

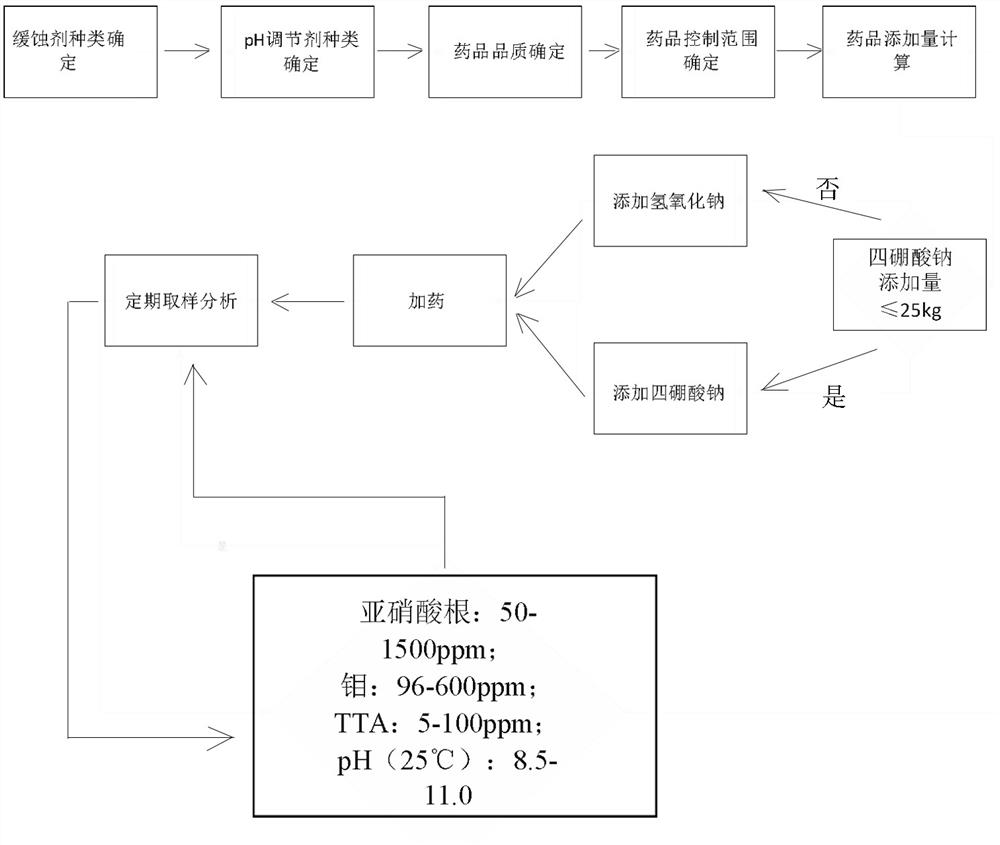

[0126] as attached figure 1As shown in the flowchart, the closed cooling water system of Sanmen 1-CCS is adopted in the present embodiment, and the corrosion inhibitor adopted in the present invention is adopted, so that in the cooling water, the concentration of nitrite is 1000ppm, and the concentration of molybdenum element is 300ppm , The concentration of TTA is 30ppm, the pH is 10.0, the content of Fe and Cu is tested (the content of Fe and Cu can directly reflect the corrosion inhibition effect of the system), and the measured data are as follows:

[0127]

Embodiment 2

[0129] The difference between this embodiment and Embodiment 1 is that the closed cooling water system of Sanmen 1-VYS is adopted in this embodiment. The concentration of nitrite is 1500ppm, the concentration of molybdenum is 600ppm, the concentration of TTA is 100ppm, and the pH is 11.0 to test the content of Fe and Cu. The measured data are as follows:

[0130]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com