A kind of preparation method of reactive dye ruby

A technology of reactive dyes and ruby, applied in the field of dyes, can solve the problems of unfavorable printing and dyeing enterprises' energy saving, emission reduction and clean production, affecting product quality and efficiency, color flower and vat difference, etc., and achieve good color fixing ability and high reactivity , The effect of reducing the amount of pollutant discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

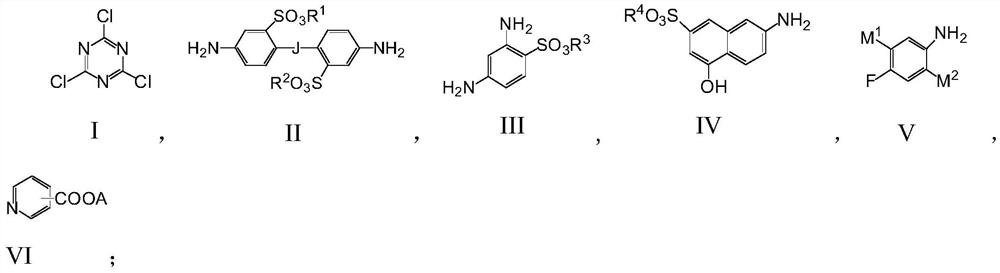

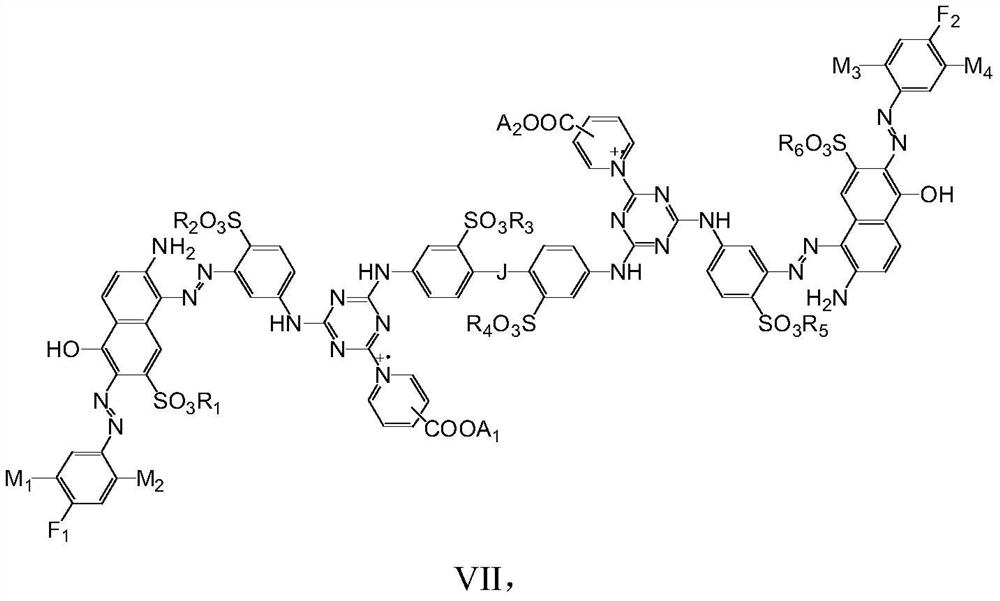

Method used

Image

Examples

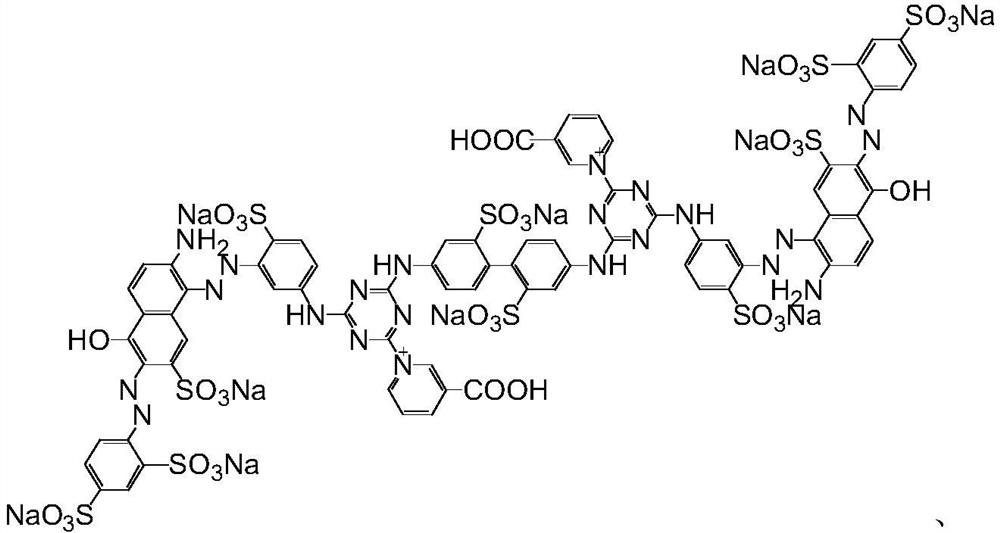

Embodiment 1

[0067] The reactive dye carnelian provided by this embodiment is prepared by the following method:

[0068] (1) will Add to crushed ice and water and stir to adding sodium bicarbonate to adjust the pH value to 2.5-3.0, and reacting at 0-5° C. for 2.5 hours to obtain the first mixed solution. in, and The feeding molar ratio is 1:0.5;

[0069] (2) Will Add to the first mixed solution, then add sodium bicarbonate to adjust the pH value to 5.5-6.0, and react at 25-30° C. for 5.5 hours to obtain the second mixed solution. in, and The feeding molar ratio is 1:0.96;

[0070] (3) adding hydrochloric acid and sodium nitrite to the second mixed solution, and reacting at 0-5° C. for 1 h to obtain the third mixed solution, wherein, The molar ratio of HCl and sodium nitrite is 1:2.0:1.0;

[0071] (4) will Add to the third mixed solution, add sodium bicarbonate to adjust the pH value to 3.5-4.0, and react at 10-15° C. for 5.5 hours to obtain the fourth mixed solution. i...

Embodiment 2

[0079] The reactive dye carnelian provided by this embodiment is prepared by the following method:

[0080] (1) will Add to crushed ice and water and stir to adding sodium bicarbonate to adjust the pH value to 2.5-3.0, and reacting at 0-5° C. for 2 hours to obtain the first mixed solution. in, and The feeding molar ratio is 1:0.5;

[0081] (2) Will Add to the first mixed solution, then add sodium bicarbonate to adjust the pH value to 5.5-6.0, and react at 25-30° C. for 5 hours to obtain the second mixed solution. in, and The feeding molar ratio is 1:0.96;

[0082] (3) adding hydrochloric acid and sodium nitrite to the second mixed solution, and reacting at 0-5° C. for 1 h to obtain the third mixed solution, wherein, The molar ratio of HCl and sodium nitrite is 1:2.0:1.0;

[0083] (4) will Add to the third mixed solution, add sodium bicarbonate to adjust the pH value to 3.5-4.0, and react at 10-15° C. for 6 hours to obtain the fourth mixed solution. in, a...

Embodiment 3

[0091] The reactive dye carnelian provided by this embodiment is prepared by the following method:

[0092] (1) will Add to crushed ice and water and stir to adding sodium bicarbonate to adjust the pH value to 2.5-3.0, and reacting at 0-5° C. for 3 hours to obtain the first mixed solution. in, and The feeding molar ratio is 1:0.5;

[0093] (2) Will Add it to the first mixed solution, then add sodium bicarbonate to adjust the pH value to 5.5-6.0, and react at 25-30° C. for 6 hours to obtain the second mixed solution. in, and The feeding molar ratio is 1:0.96;

[0094] (3) adding hydrochloric acid and sodium nitrite to the second mixed solution, and reacting at 0-5° C. for 1 h to obtain the third mixed solution, wherein, The molar ratio of HCl and sodium nitrite is 1:2.0:1.1;

[0095] (4) will Add to the third mixed solution, add sodium bicarbonate to adjust the pH value to 3.5-4.0, and react at 10-15° C. for 6 hours to obtain the fourth mixed solution. in, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com