Hexagonal radial photonic crystal film without obvious defects and preparation method thereof

A technology of obvious defects and photonic crystals, applied in optics, optical components, instruments, etc., can solve problems such as low efficiency, long time consumption, limited application, etc., and achieve the effect of reducing defects and improving stress defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

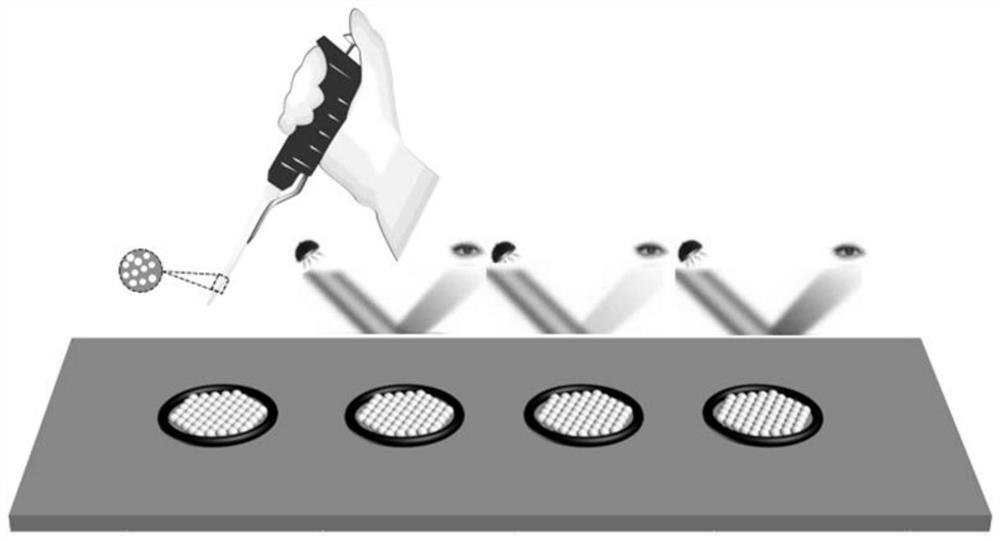

[0032] The invention provides a method for preparing a hexagonal radial photonic crystal film without obvious defects, comprising the following steps:

[0033] S1, preparing a superhydrophobic substrate;

[0034] S2, uniformly dispersing the colloidal microspheres and the binder in the solvent to make a suspension;

[0035] S3. Place the O-shaped sealing ring on the super-hydrophobic substrate obtained in step S1, so that the O-shaped sealing ring and the super-hydrophobic substrate are closely attached; then add the suspension obtained in step S2 to the In the O-shaped sealing ring, until the suspension is covered with the O-shaped sealing ring without overflowing; after the solvent is completely volatilized through drying treatment, a hexagonal radial photonic crystal film without obvious defects is obtained.

[0036] In step S1, the preparation method of the superhydrophobic substrate is: uniformly apply the polyurethane solution containing hydrophobic silicon dioxide part...

Embodiment 1

[0042] This embodiment provides a method for preparing a hexagonal radial photonic crystal film without obvious defects, comprising the following steps:

[0043] S1. Preparation of superhydrophobic substrate

[0044] Using the spraying method, spray the polyurethane solution containing 1wt% hydrophobic silica particles evenly on a clean glass slide, and place it in a drying oven at 80°C for 12 hours to obtain a contact angle with water of 152±1° superhydrophobic substrates.

[0045] S2, prepare the suspension containing colloidal particles and binder

[0046] Silica colloidal microparticles with a particle diameter of 200nm and binder polyvinylpyrrolidone with a molecular weight of 20,000 were respectively added to water, and after being fully dispersed, a suspension containing silica colloidal microparticles and polyvinylpyrrolidone was obtained. In the suspension, the mass fraction of silica colloidal particles is 1%, and the mass fraction of polyvinylpyrrolidone is 0.1%. ...

Embodiment 2~4

[0050] Embodiments 2 to 4 respectively provide a method for preparing a hexagonal radial photonic crystal film without obvious defects. Compared with Embodiment 1, the difference is that the silica colloidal microspheres used in step S2 are changed. Particle diameters, the particle diameters of the silica colloidal microspheres corresponding to Examples 2-4 are 250nm, 320nm and 450nm in sequence, and the rest of the steps are consistent with those of Example 1, and will not be repeated here.

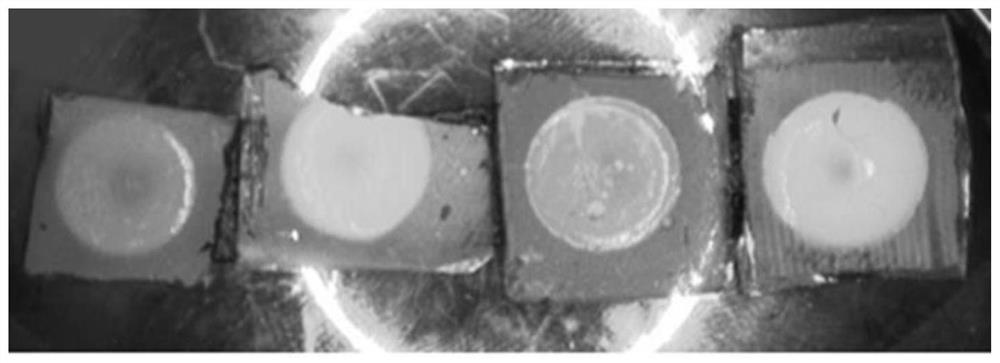

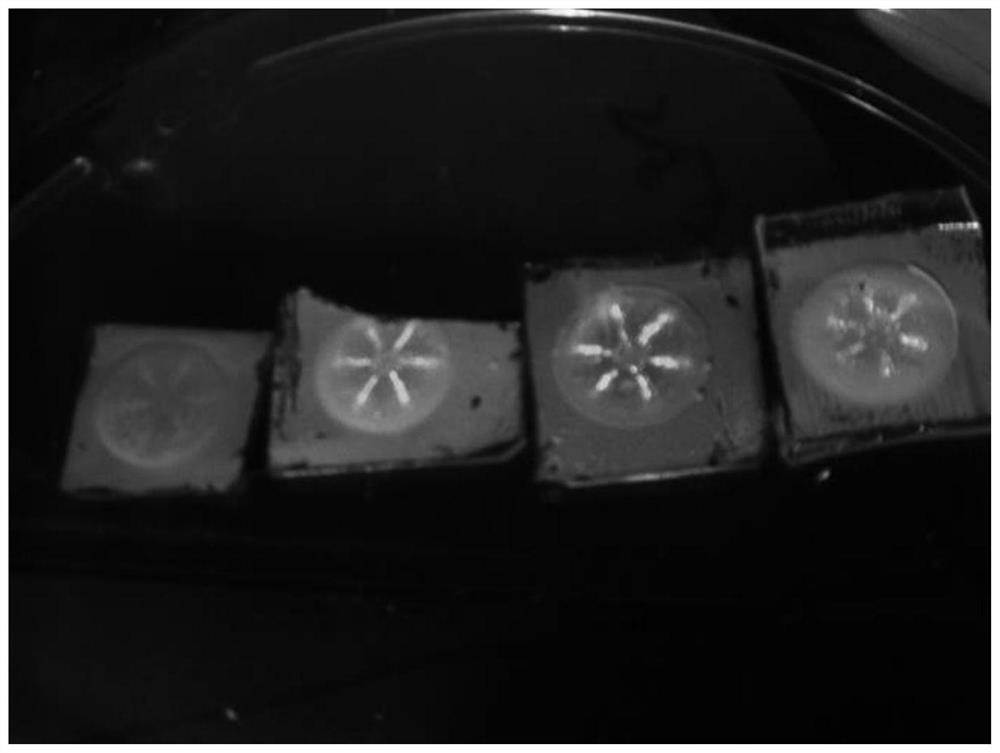

[0051] The hexagonal radial photonic crystal film prepared in Examples 1 to 4 without obvious defects was observed under light source irradiation, and the top view and the side view at 45° were as follows: figure 2 , image 3 shown. in, figure 2 , image 3 Each sample in the table represents Examples 1-4 from left to right. combine figure 2 and image 3 It can be seen that the surface of the photonic crystal film prepared in each embodiment has no obvious defects, and it is clos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com