Rare-earth-doped optical fiber with optimized background loss and preparation method of rare-earth-doped optical fiber

A rare earth-doped, optical fiber technology, applied in lasers, gaseous chemical plating, laser parts, etc., to achieve the effect of improving stress defects, low attenuation, and optimizing background loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The invention provides a method for preparing a rare earth-doped optical fiber with optimized background loss. The rare earth-doped optical fiber includes a core layer, a transitional cladding layer and a pure silicon cladding layer arranged in sequence from the inside to the outside, and the core layer and the transitional cladding layer are multi-component doped Miscellaneous silicon dioxide layer; Wherein, method comprises:

[0055] The core layer is prepared by using a rare earth halide evaporation system combined with PCVD process; the doping materials in the core layer include aluminum, ytterbium, phosphorus, and one or more alkali metal elements; the doping concentration of alkali metal elements is based on their oxides Formal calculation, the average concentration of alkali metal oxide doped in the core layer is 100ppm ~ 1000ppm;

[0056] The transition cladding layer is prepared by using a rare earth halide evaporation system combined with PCVD technology; the ...

Embodiment 1

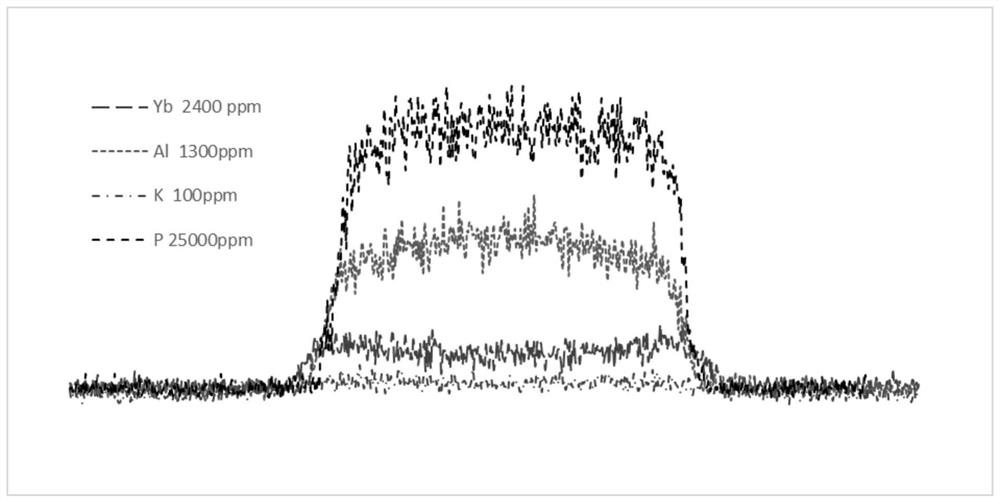

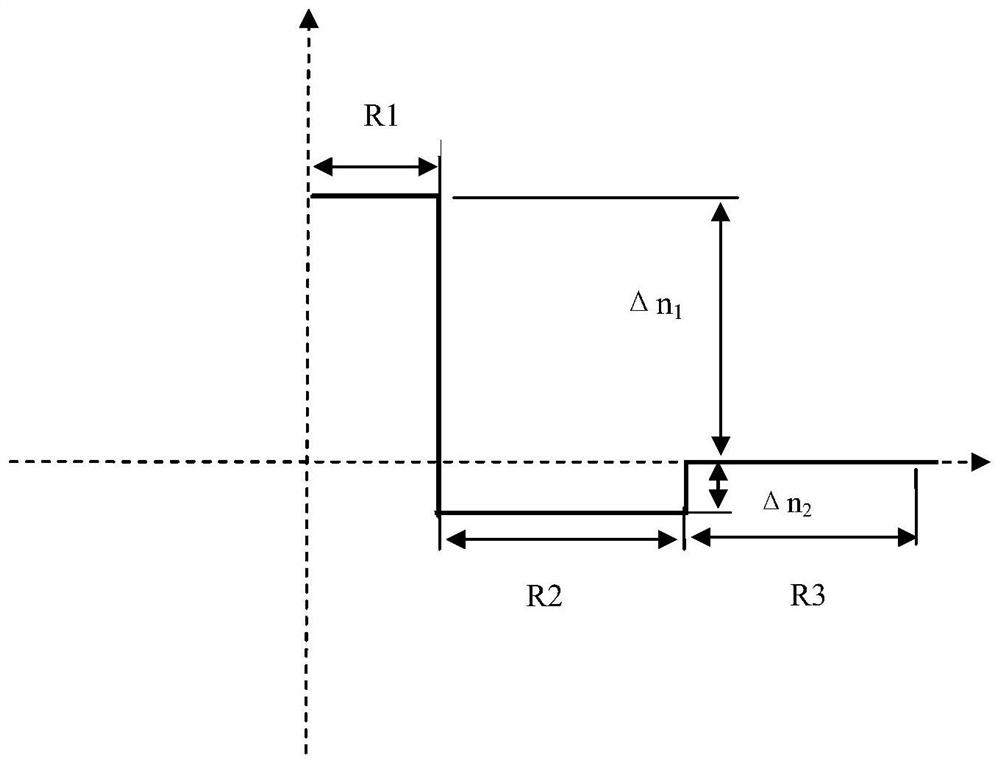

[0063] The optical fiber core layer contains oxides of aluminum, ytterbium, phosphorus, and alkali metals, and they are all approximately uniformly distributed. Among them, the aluminum oxide (Al 2 o 3 ) with a doping concentration of 13000ppm, ytterbium oxide (Yb 2 o 3 ) The doping concentration is 2400ppm, phosphorus oxide (P 2 o 5 ) with a doping concentration of 20000ppm, alkali metal oxides (K 2 The content of O) is 100ppm, the fiber core layer radius R1 is 15um, the core layer relative refractive index difference is Δn1 is 0.095%, contains the oxide of aluminum, phosphorus, alkali metal in the transitional cladding, and is approximate uniform distribution, wherein Aluminum oxide in the cladding (Al 2 o 3 ) The doping concentration is 1500ppm, phosphorus oxide (P 2 o 5 ) The doping concentration is 1600ppm, the alkali metal oxide (K 2 The content of O) is 50ppm, the radius R2 of the cladding is 60um, the relative refractive index difference of the cladding is Δn2...

Embodiment 2

[0065] The optical fiber core layer contains oxides of aluminum, ytterbium, phosphorus, fluorine, and alkali metals, and they are all approximately uniformly distributed. Among them, the aluminum oxide (Al 2 o 3 ) with a doping concentration of 15000ppm, ytterbium oxide (Yb 2 o 3 ) The doping concentration is 2500ppm, phosphorus oxide (P 2 o 5 ) doping concentration is 30000ppm, alkali metal oxide (K 2 The content of O) is 50ppm, the fiber core layer radius R1 is 10um, the relative refractive index difference of the core layer is Δn1 and is 0.08%, and the oxides of aluminum, phosphorus and alkali metals are included in the transition cladding, and are approximately evenly distributed, wherein Aluminum oxide in the cladding (Al 2 o 3 ) The doping concentration is 1000ppm, phosphorus oxide (P 2 o 5 ) with a doping concentration of 1300ppm, alkali metal oxides (K 2 The content of O) is 100ppm, the radius R2 of the cladding is 40um, the relative refractive index differenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com