High-performance carboxylic styrene-butadiene emulsion for artificial turf

A carboxylated styrene-butadiene emulsion, artificial turf technology, applied in the direction of adhesive types, hydrocarbon copolymer adhesives, etc., can solve the limitation of industrial application, no bonding strength and water resistance are improved to satisfactory results, Improve the limited and other problems to achieve excellent bond strength and water resistance, improve bond strength and water resistance, and improve the effect of stress defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

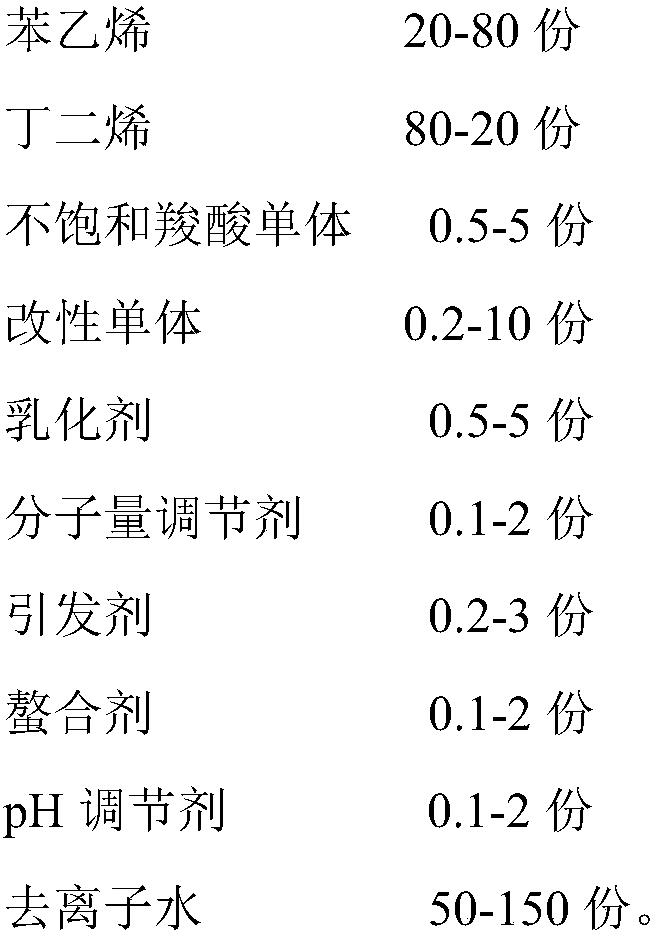

[0040] Formula: 55 parts of main monomer styrene, 45 parts of main monomer butadiene, 1 part of carboxylic acid monomer, 1 part of modified monomer vinyl trimethoxysilane, modified monomer of triethylene glycol diacrylic acid Ester 4 parts, anionic emulsifier sodium dodecylbenzene sulfonate 0.8 parts, reactive emulsifier acrylamide sodium stearate 3.2 parts, molecular weight regulator dodecyl mercaptan 0.4 parts, initiator potassium persulfate 0.6 parts , Chelating agent 0.3 parts of ethylenediaminetetraacetic acid, pH adjuster 0.5 parts of sodium hydroxide, 107 parts of deionized water.

[0041] Process: Combine 55 parts of styrene, 1 part of acrylic acid, 1 part of vinyl trimethoxysilane, 4 parts of triethylene glycol diacrylate, 0.8 parts of sodium dodecylbenzene sulfonate, 3.2 parts of Sodium acrylamide stearate, 0.4 parts of dodecyl mercaptan, 0.3 parts of ethylene diamine tetraacetic acid, and 80 parts of deionized water were put into the reactor, the stirring device was tu...

Embodiment 2

[0043] Formula: 55 parts of main monomer styrene, 45 parts of main monomer butadiene, 1 part of carboxylic acid monomer, 1 part of modified monomer vinyl trimethoxysilane, modified monomer of triethylene glycol diacrylic acid Ester 4 parts, anionic emulsifier sodium dodecylbenzene sulfonate 1.2 parts, reactive emulsifier acrylamide sodium stearate 2.8 parts, molecular weight regulator dodecyl mercaptan 0.4 parts, initiator potassium persulfate 0.6 parts , Chelating agent 0.3 parts of ethylenediaminetetraacetic acid, pH adjuster 0.5 parts of sodium hydroxide, 107 parts of deionized water.

[0044] The polymerization process was unchanged, and the same as in Example 1, the carboxyl styrene butadiene emulsion was prepared.

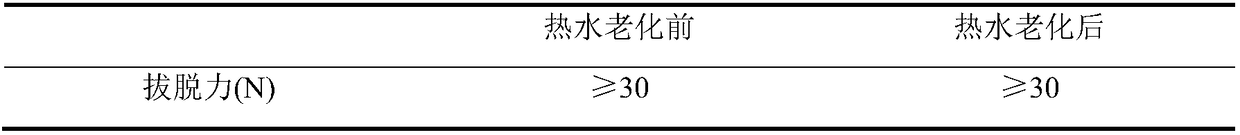

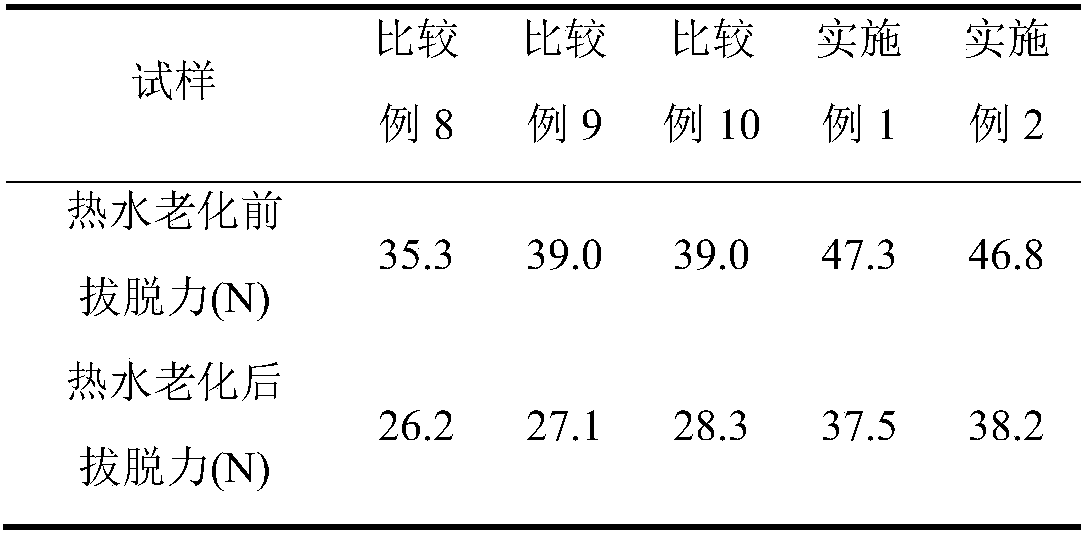

[0045] Table 2 Emulsion application performance test results

[0046]

[0047] It can be seen from Table 2 that Comparative Examples 8, 9, and 10 were modified with silane-type modified monomers and reactive emulsifiers, silane-type modified monomers and multiple d...

Embodiment 3

[0049] Formula: 55 parts of main monomer styrene, 45 parts of main monomer butadiene, 1 part of carboxylic acid monomer methacrylic acid, 1.5 parts of modified monomer vinyl triisopropoxysilane, modified monomer of tripropylene glycol Diacrylate 3.5 parts, anionic emulsifier sodium dodecylbenzene sulfonate 2.2 parts, reactive emulsifier 2-acrylamide-2,2-dimethylethanesulfonate sodium 1.8 parts, molecular weight regulator dodecyl 0.4 parts mercaptan, 0.6 parts potassium persulfate as initiator, 0.3 parts ethylenediaminetetraacetic acid as chelating agent, 0.5 parts sodium hydroxide as pH regulator, and 107 parts deionized water.

[0050] Process: Combine 55 parts of styrene, 1 part of methacrylic acid, 1.5 parts of vinyl triisopropoxysilane, 3.5 parts of tripropylene glycol diacrylate, 2.2 parts of sodium dodecylbenzene sulfonate, 1.8 parts Parts of sodium 2-acrylamide-2,2-dimethylethanesulfonate, 0.4 parts of dodecyl mercaptan, 0.3 parts of ethylenediaminetetraacetic acid, and 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com