Composite oxide-coated electroconductive separation membrane for water treatment and manufacturing method therefor

A manufacturing method and oxide technology, applied in chemical instruments and methods, osmotic/dialysis water/sewage treatment, semi-permeable membrane separation, etc., can solve the problem of shortened water demand cycle, waste water reliance on entrusted treatment/disposal, and inability to effectively remove Trace pollutants, etc., to prevent membrane fouling and excellent treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Hereinafter, the present invention will be described in more detail with reference to examples. These embodiments are only used to illustrate the present invention more specifically, and it should be clear to those skilled in the art that the scope of the present invention is not limited to these embodiments according to the gist of the present invention.

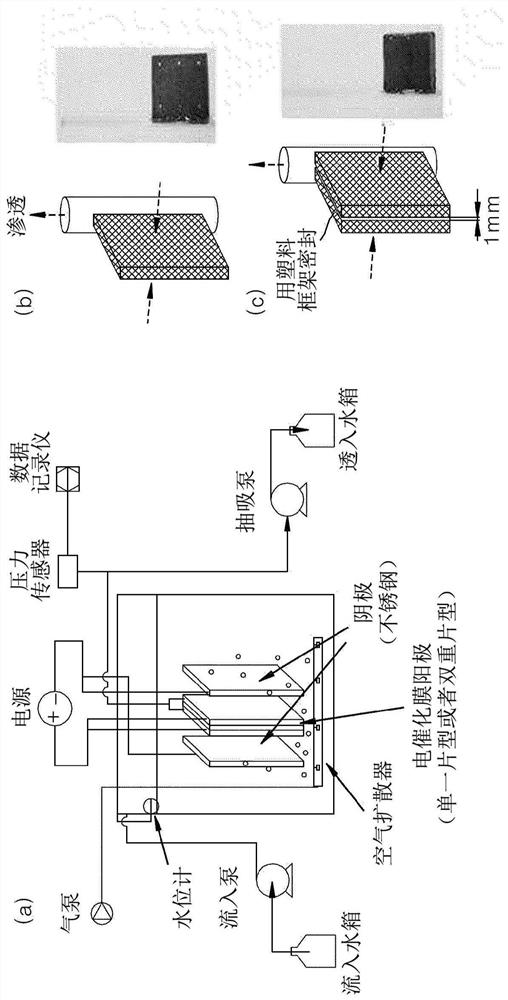

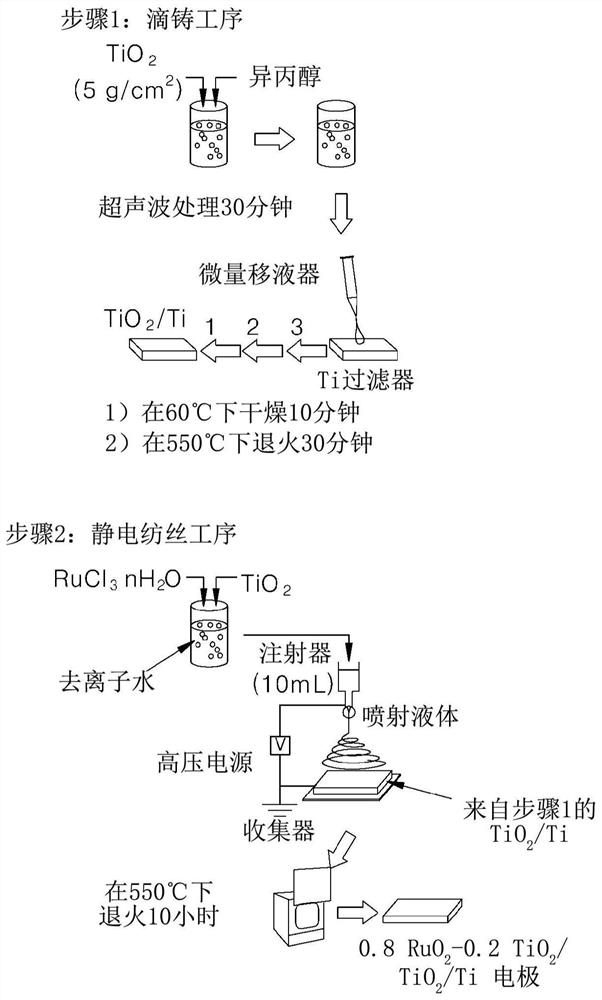

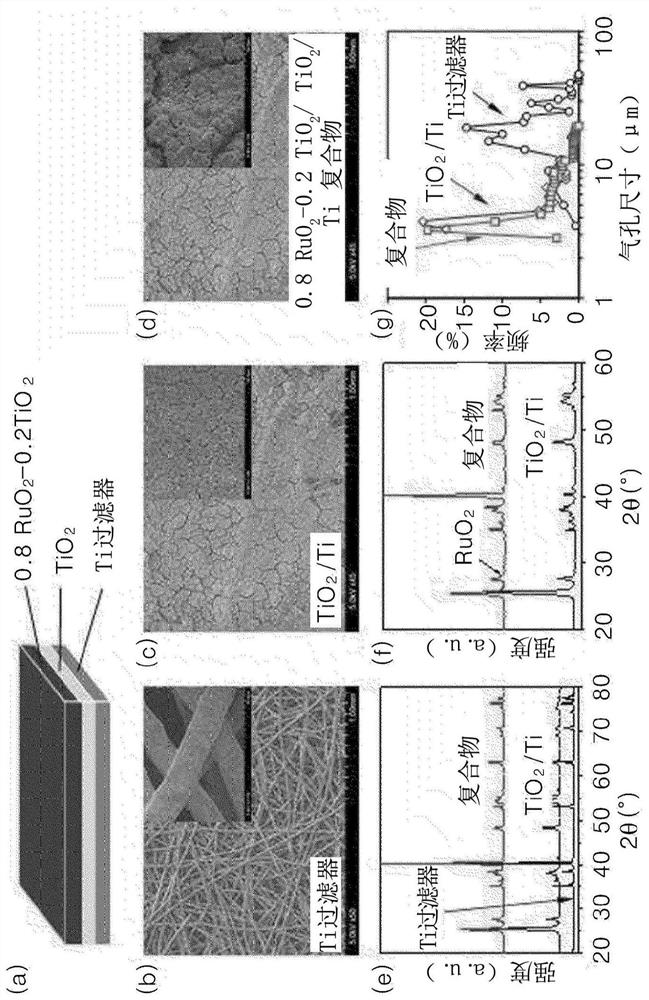

[0052] Manufacture of composite oxide separation membrane

[0053] figure 2 A method for manufacturing an electrocatalytic separation membrane according to an embodiment of the present invention is shown. refer to figure 2 , electrocatalytic filters were prepared using the drop casting technique (step 1) as well as the electrospinning coating technique (step 2). The exposed Ti filter (width 7.5 cm, length 6.5 cm, thickness 0.5 mm) was washed with lotion solution and ultrasonicated for 15 min in alkaline solution (5% NaOH) and acid solution (10% oxalic acid) at 90 °C for 1 hour, washed with distilled water and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com