A rolling forming process of complex high-strength thin plate

A forming process, high rib technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

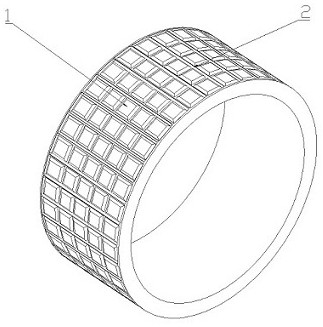

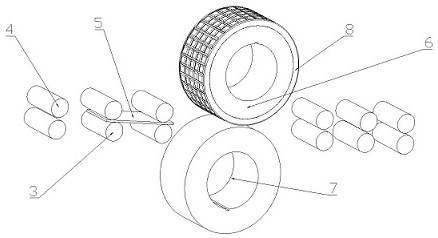

[0034] To produce plate thickness h 1 =8mm, rib height h 2 =16mm plate as an example:

[0035] Production parameters: blank thickness =30mm; the width of the blank b=400mm; the required plate thickness h 1 =8mm; Rib height h 2 =16mm; roll radius R=500mm; friction coefficient =0.35;

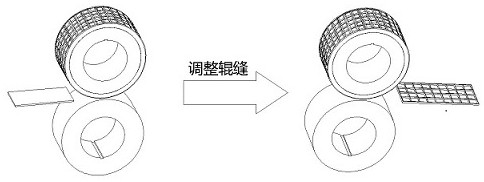

[0036] The rolling speed is 45mm / s. Firstly, the required groove with a depth of d=8mm is processed on the roll, and the billet is transported to the gap between the rolls through the lower conveying roller. In the rolling process, since the rolling deformation resistance and deformation temperature of the sleeve are much higher than that of the billet, all the deformation is completed by the billet during the deformation, and the deformation of the roll and the sleeve is negligible. After that, the blank thickness becomes the required plate thickness h 1 =8mm, and due to the action of the roller, the resulting height is h 2 =16mm rib body;

[0037] It is stipulated that the width of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com