High-thermal-conductivity single-component thermal-conductive gel and preparation method thereof

A single-component, high thermal conductivity technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of high thermal resistance, large endothermic and exothermic curing shrinkage, poor bonding performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

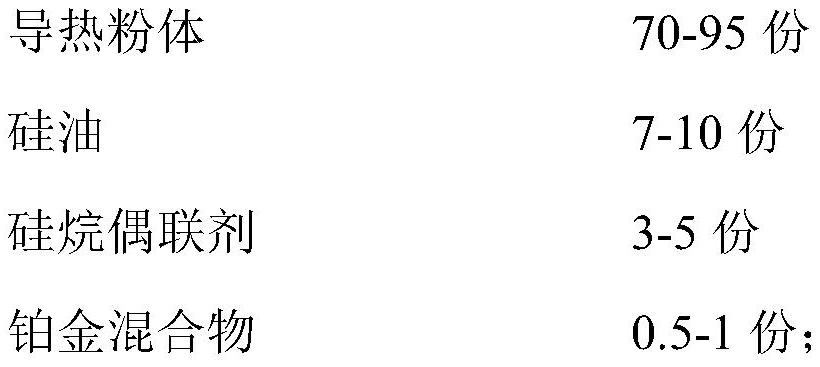

[0042] A high thermal conductivity one-component thermal conductive gel of this embodiment includes the following raw materials in parts by weight:

[0043]

[0044] Wherein, the thermally conductive powder is composed of the following raw materials in parts by weight:

[0045] 68 parts of stearic acid modified alumina

[0046] Aluminum hydroxide 12 parts

[0047] Zinc oxide 20 parts;

[0048] Wherein, the particle size of the stearic acid-modified aluminum oxide is 58 microns, the particle size of aluminum hydroxide is 10 microns, and the particle size of zinc oxide is 3 microns.

[0049] Wherein, the silicone oil is a combination of dimethyl silicone oil and vinyl silicone oil with a viscosity of 1000 cps at 25°C.

[0050] Wherein, the silane coupling agent is a mixture composed of octyltrimethoxysiloxane, diethoxymethylphenylsilane and stearic acid in a mass ratio of 1:0.5:2.

[0051] Wherein, the concentration of the platinum mixture is 1600ppm.

[0052] The prepar...

Embodiment 2

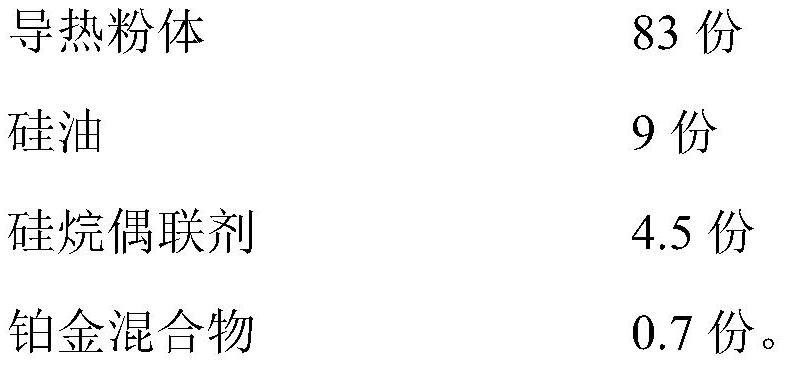

[0062] A high thermal conductivity one-component thermal conductive gel of this embodiment includes the following raw materials in parts by weight:

[0063]

[0064] Wherein, the thermally conductive powder is composed of the following raw materials in parts by weight:

[0065] 60 parts of stearic acid modified alumina

[0066] Aluminum hydroxide 10 parts

[0067] Zinc oxide 15 parts;

[0068] Wherein, the particle size of the stearic acid-modified aluminum oxide is 30 microns, the particle size of aluminum hydroxide is 8 microns, and the particle size of zinc oxide is 1 micron.

[0069] Wherein, the silane coupling agent is a mixture composed of octyltrimethoxysiloxane, diethoxymethylphenylsilane and stearic acid in a mass ratio of 1:0.8:2.

[0070] Wherein, the concentration of the platinum mixture is 3000ppm.

[0071] The preparation method of the high thermal conductivity one-component thermally conductive gel of this embodiment is basically the same as that of Exam...

Embodiment 3

[0075] A high thermal conductivity one-component thermal conductive gel of this embodiment includes the following raw materials in parts by weight:

[0076]

[0077]

[0078] Wherein, the thermally conductive powder is composed of the following raw materials in parts by weight:

[0079] 70 parts of stearic acid modified alumina

[0080] Aluminum hydroxide 20 parts

[0081] 30 parts of zinc oxide;

[0082] Wherein, the particle size of the stearic acid-modified aluminum oxide is 80 microns, the particle size of aluminum hydroxide is 30 microns, and the particle size of zinc oxide is 5 microns.

[0083] Wherein, the silane coupling agent is a mixture composed of octyltrimethoxysiloxane, diethoxymethylphenylsilane and stearic acid in a mass ratio of 1:0.4:2.

[0084] Wherein, the concentration of the platinum mixture is 1200ppm.

[0085] The preparation method of the high thermal conductivity one-component thermally conductive gel of this embodiment is basically the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com