Production method of high-strength non-adhesive fracturing propping agent

A technology of fracturing proppant and production method, which is applied in the field of fracturing proppant, which can solve the problems of mutual adhesion of proppant, unfavorable proppant fluidity, poor flow diversion and strength, etc., so as to ensure the support diversion effect , Guaranteed strength, non-sticking and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

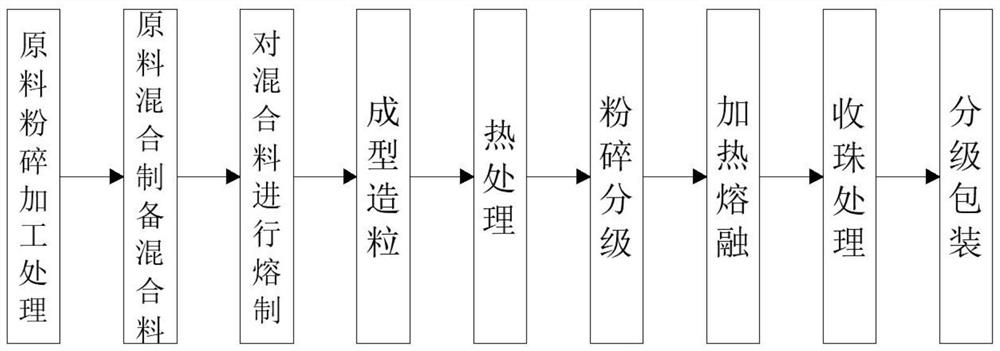

Image

Examples

Embodiment

[0046] First, crush quartz sand, soda ash, limestone, feldspar and other raw materials, and then wash and separate them to remove impurities. After standing in water for 3 hours, take them out and dry them to a dry state. At the same time, remove iron from the dried raw material powder. , to ensure the quality of raw materials, the ratio of quartz sand: soda ash: limestone: feldspar = 1: 0.8: 0.95: 0.45 is used to mix the raw materials, and prepare them as batch materials for later use. Heating at ℃ to form a liquid proppant that is uniform, free of bubbles, and meets the molding requirements, and then the liquid proppant is molded, and the molding process is granulated by a granulator, and then the molded proppant is annealed and quenched. The fracturing proppant is heat-treated to clean or generate stress, phase separation or crystallization inside the proppant, and change the structural state of the proppant to ensure the strength of the proppant, and the heat-treated proppa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com