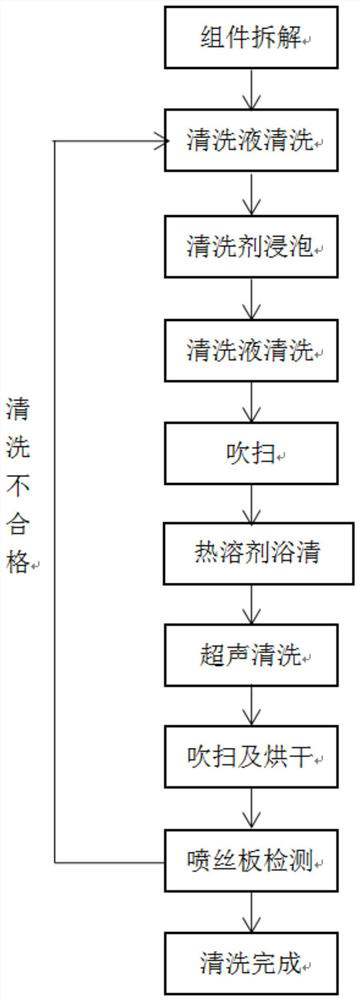

Spinneret plate cleaning process

A spinneret and process technology, which is applied to the cleaning field of wet spinning spinnerets, can solve the problem of large outflow resistance of spinning solution from spinneret holes, adhesion to spinneret holes, and increase of fiber filaments. and other problems, to achieve the effect of improving the service life, reducing the amount of fiber wool and low damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

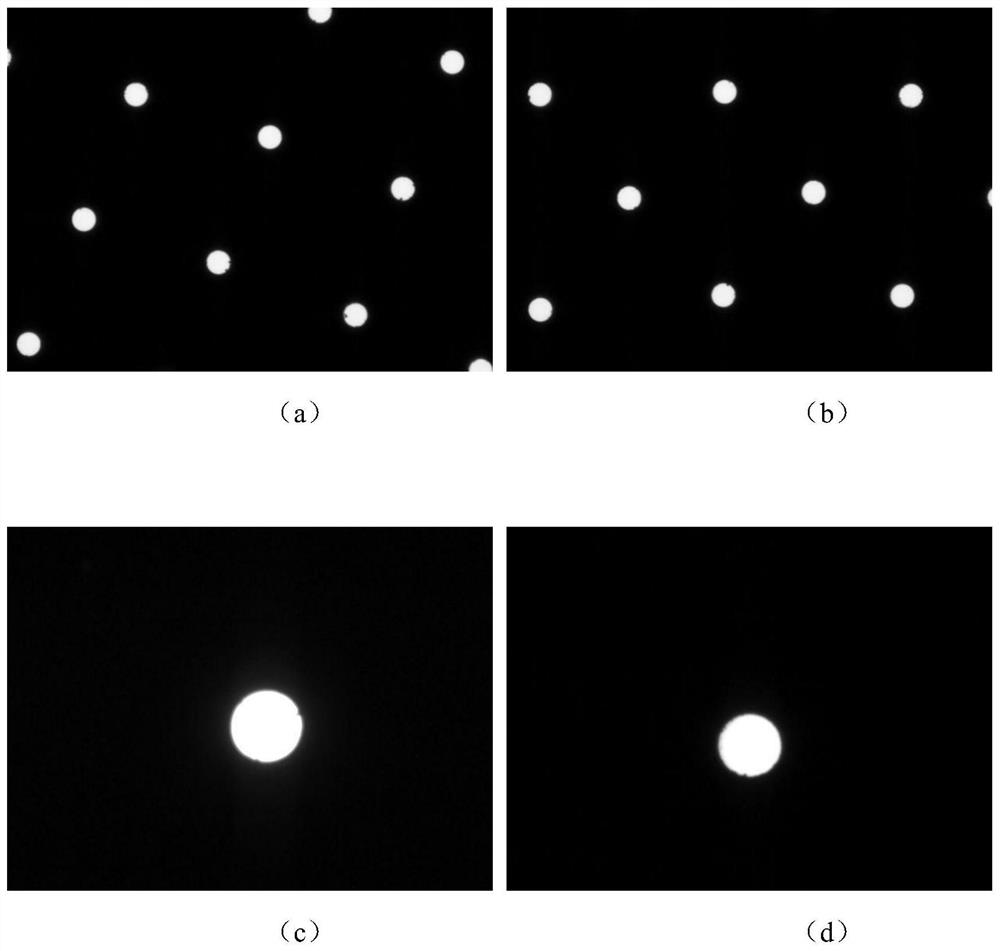

[0052] Disassemble the spinneret assembly replaced on the production line. First, clean the spinneret with deionized water. The spinneret is glued with spinning solution and plasticized in deionized water to peel off the surface crust as much as possible. skin, soak the cleaned spinneret in the prepared lye for 4 hours; wash the soaked spinneret with deionized water, and then blow it with compressed air until there are no water drops. Wherein, the lye is prepared through the following process: according to the mass ratio of sodium hydroxide: ethanol: deionized water 1:25:0.2, sodium hydroxide and ethanol are added to the deionized water and mixed evenly.

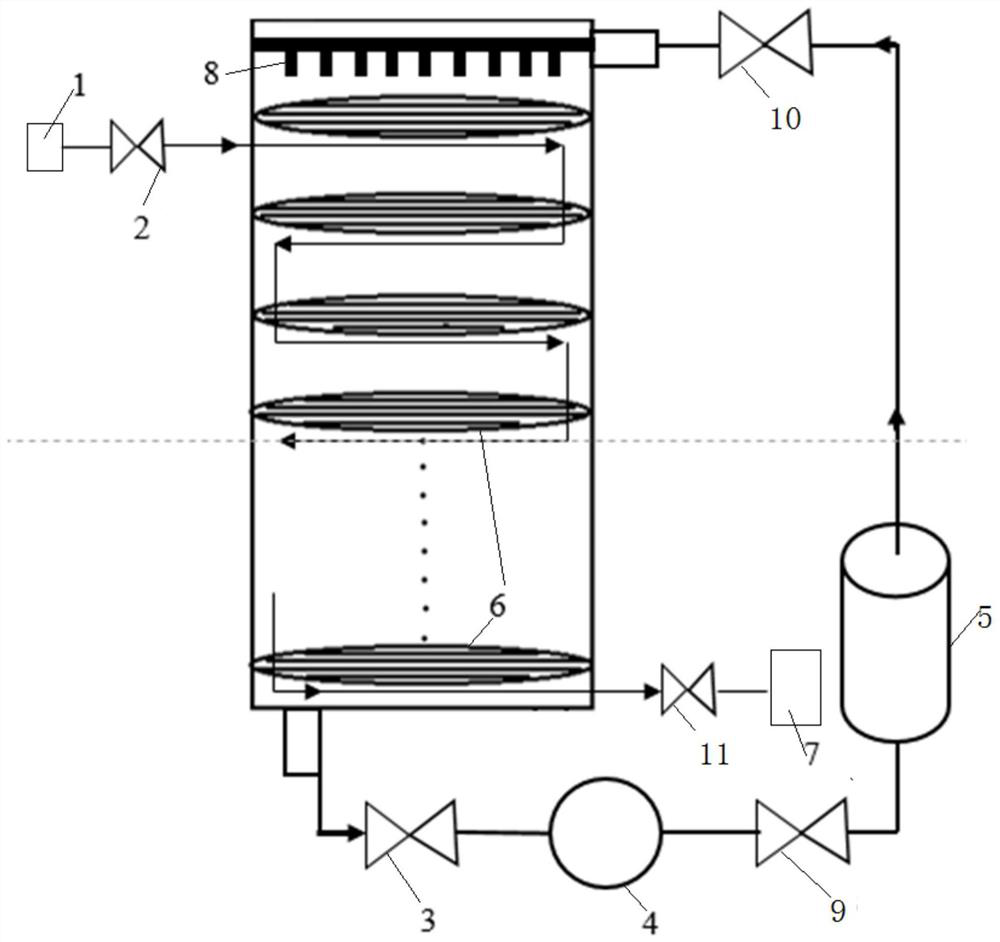

[0053] Next, put the spinneret into the spinneret circulation cleaning system, treat it with a hot solvent at 100°C for 2 hours, then place the spinneret in an ultrasonic cleaning machine for cleaning, the ultrasonic cleaning temperature is 50°C, and the cleaning time is 30min. The air blows the spinneret, and then puts it i...

Embodiment 2

[0055] Disassemble the spinneret assembly replaced on the production line. First, clean the spinneret with deionized water. The spinneret is glued with spinning solution and plasticized in deionized water to peel off the surface crust as much as possible. skin, soak the cleaned spinneret in the prepared lye for 4 hours; wash the soaked spinneret with deionized water, and then blow it with compressed air until there are no water droplets. Wherein, the lye is obtained through the following process: according to the mass ratio of sodium hydroxide: ethanol: deionized water 1:40:0.3, sodium hydroxide and ethanol are added to the deionized water, and mixed evenly.

[0056] Next, put the spinneret into the spinneret circulation cleaning system, treat it with a hot solvent at 100°C for 3 hours, then put the spinneret in an ultrasonic cleaning machine for cleaning, the ultrasonic cleaning temperature is 50°C, and the cleaning time is 30min. The air blows the spinneret, and then puts it...

Embodiment 3

[0058] Disassemble the spinneret assembly replaced on the production line. First, clean the spinneret with deionized water. The spinneret is glued with spinning solution and plasticized in deionized water to peel off the surface crust as much as possible. skin, soak the cleaned spinneret in the prepared lye for 8 hours; wash the soaked spinneret with deionized water, and then blow it with compressed air until there are no water drops. Among them, the lye is prepared through the following process: according to the mass ratio of sodium hydroxide: ethanol: deionized water 1:30:0.4, sodium hydroxide and ethanol are added to the deionized water and mixed evenly.

[0059] Next, put the spinneret into the spinneret circulation cleaning system, treat it with a hot solvent at 100°C for 2 hours, then place the spinneret in an ultrasonic cleaning machine for cleaning, the ultrasonic cleaning temperature is 50°C, and the cleaning time is 30min. The air blows the spinneret, and then puts i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com