Efficient dryer for camellia oleifera production and processing

A dryer, high-efficiency technology, applied in the direction of drying solid materials without heating, dryers, drying solid materials, etc., can solve the problems of affecting drying efficiency, no dehydration, inconvenient drying, etc., to improve drying efficiency and speed up drying , The effect of speeding up the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

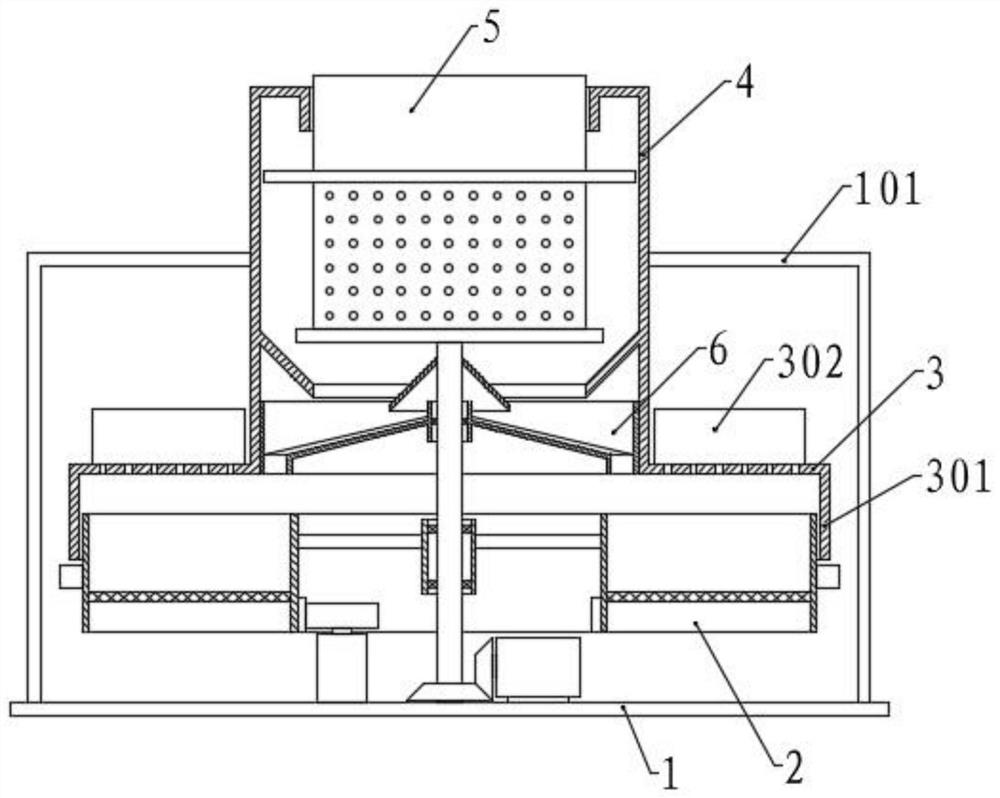

[0054] Please refer to the accompanying drawings, the present invention provides a technical solution: a high-efficiency drying machine for camellia oleifera production and processing, including a base 1, a material spreading assembly 2 is arranged above the base 1, and a fixed box 4 is arranged above the material spreading assembly 2 , and both sides of the fixed box 4 are fixedly connected to the base 1 through the support rod 101;

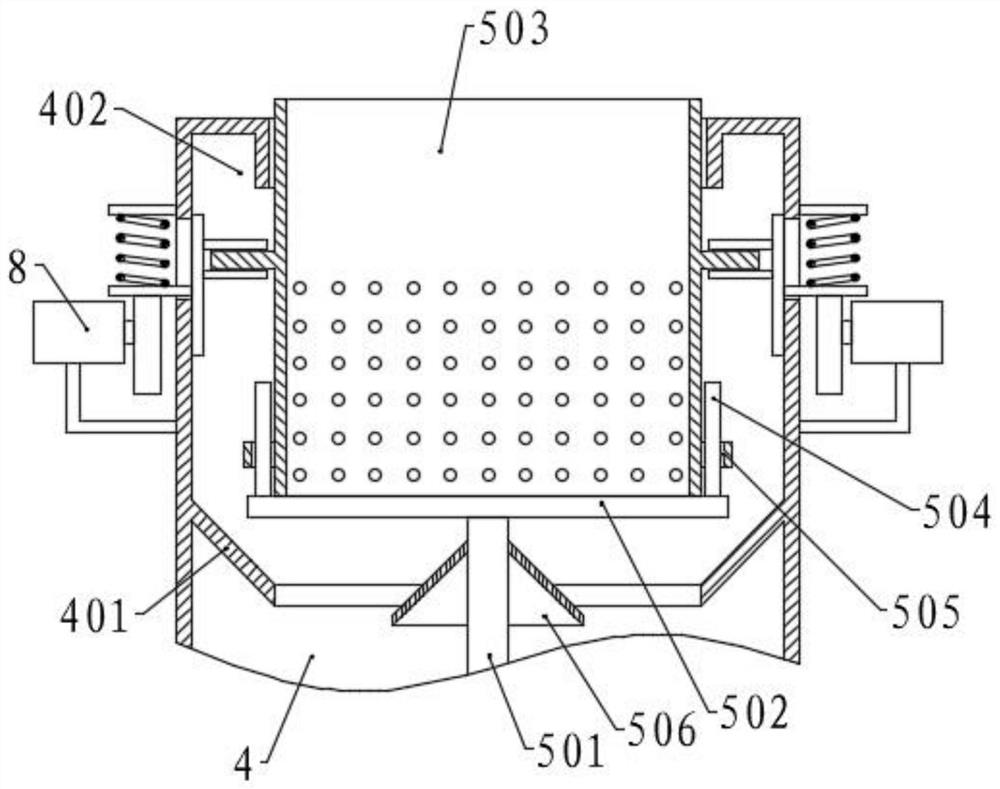

[0055] The upper part of the inner cavity of the fixed box 4 is provided with a dehydration assembly 5, and the position corresponding to the dehydration assembly 5 on the side wall of the fixed box 4 is uniformly provided with a plurality of lifting assemblies 8 along the circumferential direction, and the bottom of the fixed box 4 is fixed with a collecting hopper 401, And the conversion assembly 6 is provided below the collecting hopper 401;

[0056] The outside of the bottom of the fixed box 4 is fixed with an annular plate 3, and two drying...

Embodiment 2

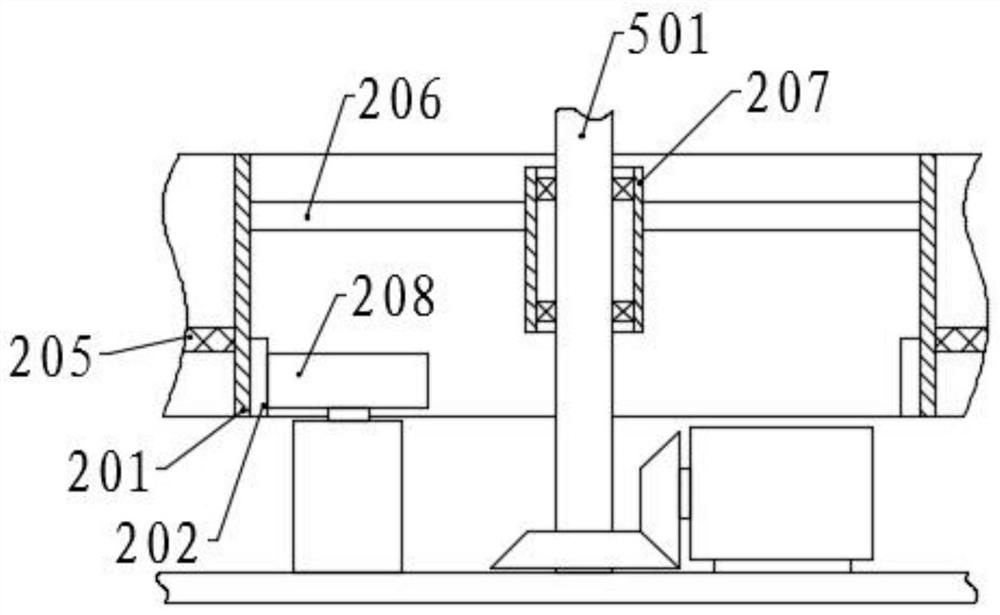

[0062] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the paving assembly 2 includes an inner ring cylinder 201 and an outer ring cylinder 203, and a horizontal ring is fixed between the inner ring cylinder 201 and the outer ring cylinder 203. net 205, and the outer edge of the annular plate 3 is fixed with a vertical annular side plate 301, and the side plate 301 is sleeved on the top of the outer ring cylinder 203, and the net 205 is placed on the radial direction. The trough is provided with a blanking assembly, and the center of the inner ring cylinder 201 is provided with a rotating cylinder 207, and the outer wall of the rotating cylinder 207 is evenly fixed with a plurality of rotating rods 206 along the circumferential direction, and through the rotating rods 206 and the inner ring cylinder 201 is fixedly connected, and the bottom of the inner ring cylinder 201 is fixed with an inner ring gear 202, and the inner ri...

Embodiment 3

[0075] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that a material shifting assembly is provided on the ring plate 3 corresponding to the position between the front sides of the two drying assemblies, and the material shifting assembly includes a material set on the inner ring cylinder 201 and the cross bar 10 between the outer ring cylinder 203, the bottom of the cross bar 10 is uniformly fixed with a plurality of vertical shifting rods 1001, and the cross section of the shifting rods 1001 is triangular, so that the shape of the shifting rods 1001 will The tiled camellia seeds are separated, the top surface of the cross bar 10 is fixed with a vertical bar, and the position corresponding to the vertical bar on the annular plate 3 is provided with a bar groove, and the top of the vertical bar passes through the bar groove, and a U-shaped sliding frame is fixed 1002, a spring is provided between the inner end of the sliding fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com