Filling system and method for blasting construction

A technology of blasting design and pyrotechnics, which is applied in blasting and other directions, can solve problems such as complex statistics, error-prone data, and incorrect data, and achieve the effects of simple system operation, high practicability, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

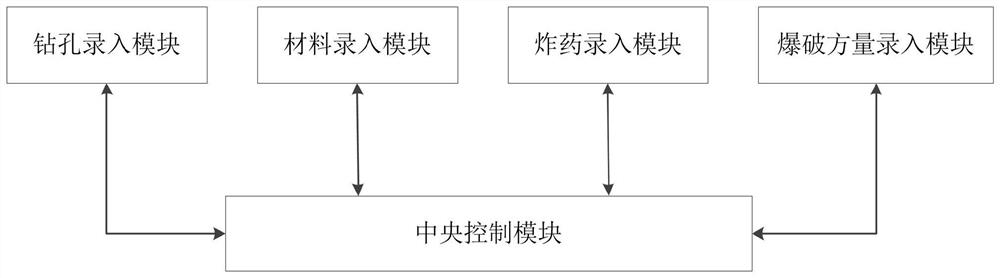

[0029] Such as figure 1 As shown, this embodiment provides a blasting construction reporting system, including a central control module, a drilling input module, a material input module, an explosive input module, and a blasting volume input module; a drilling input module, a material input module, and an explosive input module And the blasting volume input module is connected with the central control module; the drilling input module is used for inputting actual drilling information, and the actual drilling information includes actual hole position, drilling inclination and hole depth; the material input module is used for Entering pyrotechnic materials and blasting auxiliary materials used in blasting; the explosive input module is used to input the explosive charge of each blast hole; the blasting volume input module is used to input the blasting volume after the blasting excavation is completed. The central control module is used to store blasting drilling design informati...

Embodiment 2

[0039] This embodiment provides a specific usage method of the blasting construction reporting system described in Embodiment 1.

[0040] When a mine plans to conduct open-pit blasting in a certain area, the first step is to enter the drilling data. The drilling rig personnel determine the number, location and depth of blasting holes in the blasting area according to the design drawings in the system. During the drilling process, they construct 32 blasting holes in the blasting area according to the drawings. For blastholes, fill in the actual drilling footage information. For example, for blastholes numbered 2-6, the design hole depth is 17.5m, the drilling inclination angle is 90°, and the actual footage is 17.6m. Select the blasthole number in the system as For the 2-6 blast holes, enter the drilling footage: 17.6m, and the drilling inclination angle is 90°.

[0041] Then there is data entry during blasting construction. There are 32 blastholes in this explosion area, 32 ...

Embodiment 3

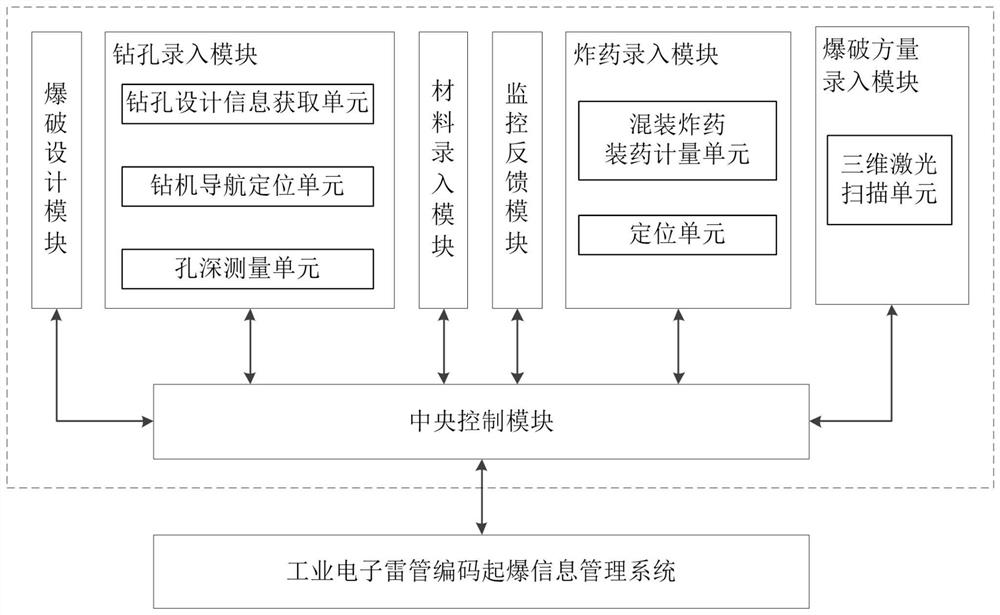

[0049] Such as figure 2 As shown, compared with the blasting construction reporting system of this embodiment described in Example 1, the blasting construction reporting system provided in this example also includes a blasting design module connected to the central control module, and the drilling input module includes drilling A hole design information acquisition unit, a drilling rig navigation and positioning unit, and a hole depth measurement unit; the explosive input module includes a mixed explosive charge metering unit and a positioning unit; the blasting volume input module includes a three-dimensional laser scanning unit. The drilling rig navigation and positioning unit, the hole depth measurement unit, the mixed explosive charge metering unit and the three-dimensional laser scanning unit described in this embodiment can be the existing drilling rig navigation automatic positioning system, the hole depth automatic measurement system, the on-site mixed explosive Drug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com