Water-based surface polyurethane resin for automobile leather and preparation method of water-based surface polyurethane resin

A polyurethane resin and automotive leather technology, applied in the field of polyurethane automotive leather, can solve the problems of vulcanization resistance, friction resistance, weather resistance, and pollution resistance, etc., and achieve easy industrial production, long service life, and good vulcanization resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

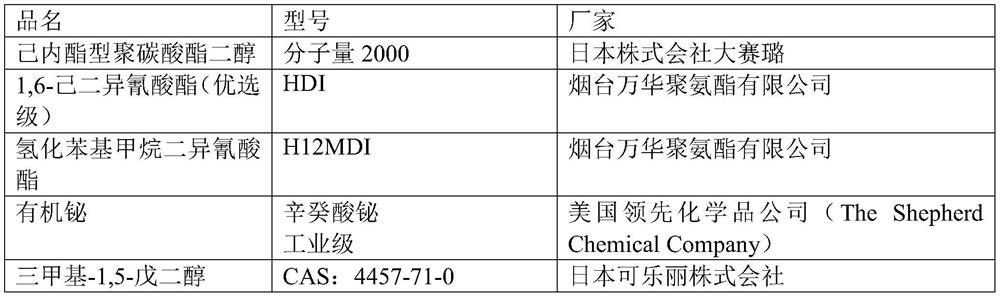

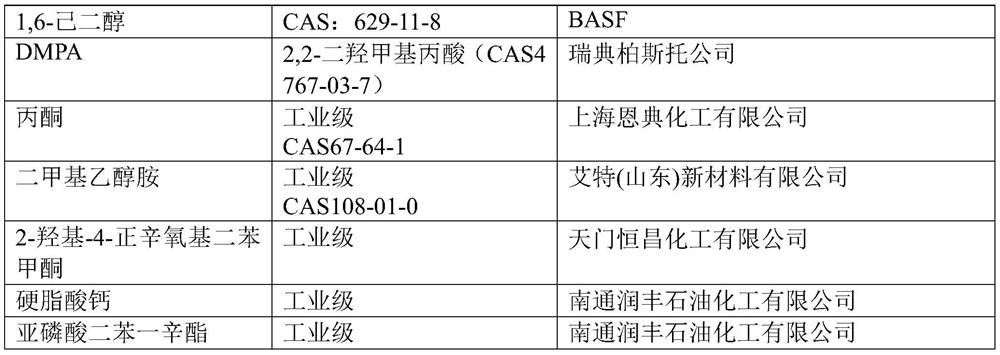

Method used

Image

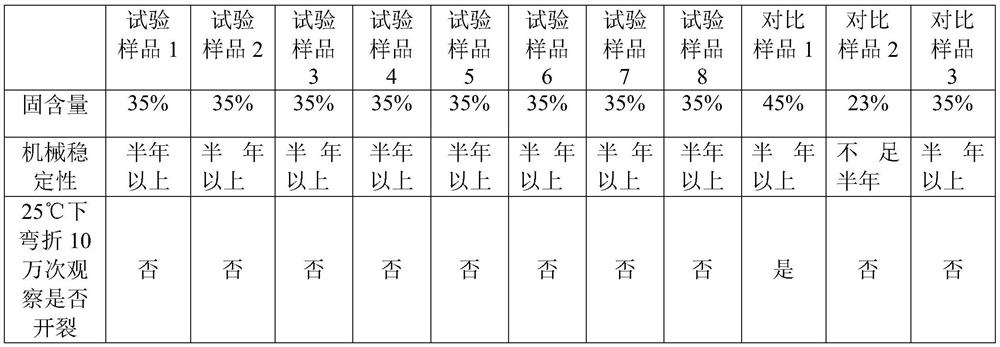

Examples

Embodiment 1

[0039] A water-based polyurethane resin for the surface layer of automobile leather, which is polymerized by raw materials comprising the following parts by weight: 43 parts of caprolactone polycarbonate diol with a molecular weight of 2000, 5 parts of HDI, 20 parts of H12MDI, and 0.08 parts of organic Bismuth, 3 parts of 1,5-pentanediol, 3.5 parts of DMPA, 20 parts of acetone, 2 parts of dimethylethanolamine, 60 parts of deionized water.

[0040] A method for preparing a water-based surface layer polyurethane resin for automobile leather, specifically: at a stirring speed of 150 rpm, sequentially add 43 parts of caprolactone-type polycarbonate diol with a molecular weight of 2000, 5 parts of HDI, and 20 parts of H12MDI , 0.08 parts of organic bismuth, react at 88.9°C for 2.0 hours; then add 3 parts of 1,5-pentanediol, 3.5 parts of DMPA, and 8 parts of acetone at 80°C, react for 2 hours, the reactor must be equipped with acetone condensation Reflux device and pressure relief d...

Embodiment 2

[0042] A water-based polyurethane resin for the surface layer of automobile leather, which is polymerized by the following raw materials in parts by weight: 45 parts of caprolactone polycarbonate diol with a molecular weight of 2000, 3 parts of HDI, 18 parts of IPDI, and 0.08 parts of organic bismuth , 3 parts of 1,5-pentanediol, 1 part of 1,6-hexanediol, 3.7 parts of DMPA, 20 parts of acetone, 2 parts of dimethylethanolamine, and 60 parts of deionized water.

[0043] A method for preparing a water-based surface layer polyurethane resin for automobile leather, specifically: at a stirring speed of 150 rpm, sequentially add 45 parts of caprolactone-type polycarbonate diol with a molecular weight of 2000, 3 parts of HDI, and 18 parts of IPDI , 0.08 parts of organic bismuth, reacted for 2.0 hours at 89.1°C; then added 3 parts of 1,5-pentanediol, 1 part of 1,6-hexanediol, 3.7 parts of DMPA, 8 parts of acetone at 80°C, React for 2 hours, the reactor must be equipped with an acetone ...

Embodiment 3

[0045] A water-based surface layer polyurethane resin for automotive leather, which is polymerized by the following raw materials in parts by weight: 40 parts of caprolactone polycarbonate diol with a molecular weight of 2000, 27 parts of H12MDI isocyanate, 0.08 parts of organic bismuth, 2 parts 1,5-pentanediol, 2 parts of 1,6-hexanediol, 4.3 parts of DMPA, 20 parts of acetone, 2 parts of dimethylethanolamine, 65 parts of deionized water.

[0046] A method for preparing a water-based surface layer polyurethane resin for automobile leather, specifically: at a stirring speed of 150 rpm, sequentially add 40 parts of caprolactone-type polycarbonate diol with a molecular weight of 2000, 27 parts of H12MDI isocyanate, 0.08 parts of Organic bismuth, at 89.0°C, reacted for 2.0 hours; then added 2 parts of 1,5-pentanediol, 2 parts of 1,6-hexanediol, 4.3 parts of DMPA, 8 parts of acetone at 80°C, reacted for 2 hours , the reactor must be equipped with an acetone condensing reflux device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com