Efficient alkaline dispersion ash removal degreasing agent

An ash degreaser and degreaser technology, applied in the field of high-efficiency alkaline dispersion ash degreaser, can solve the problems of low grease efficiency, poor effect, and difficulty in decomposing, so as to ensure work effect, improve degreasing efficiency, and improve mixing. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

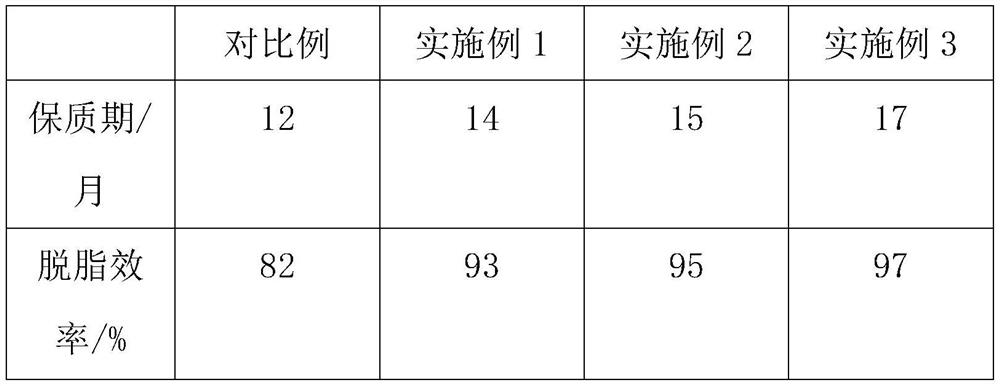

Examples

Embodiment 1

[0033] Step 1: Preparation of equipment and related materials: use the cleaning device to fully clean the equipment participating in the reaction, then power on the equipment and start it, enter the working standby state, conduct a comprehensive inspection of the degreasing agent participating in the reaction, and eliminate unqualified products;

[0034] Step 2: Basic mixing of materials: mix all main ingredients (20 parts of sodium ethylenediamine tetramethylene phosphonate, 30 parts of nitrilotriacetic acid, 10 parts of iminodisuccinic acid, dioctyl sodium sulfosuccinate 20 parts, 2 parts of sodium hydroxide, 10 parts of tetrasodium EDTA, 10 parts of isooctyl alcohol polyoxyethylene ether, 25 parts of cocamidopropyl betaine, 40 parts of coconut acid diethanolamide, 60 parts of polyvinylpyrrolidone, 15 parts of benzotriazole and 10 parts of sodium lignosulfonate) were poured into the reaction kettle, and after pouring, the stirring equipment was started to mix and stir the mat...

Embodiment 2

[0039]Step 1: Preparation of equipment and related materials: use the cleaning device to fully clean the equipment participating in the reaction, then power on the equipment and start it, enter the working standby state, conduct a comprehensive inspection of the degreasing agent participating in the reaction, and eliminate unqualified products;

[0040] Step 2: basic mixing of materials: all main ingredients (25 parts of sodium ethylenediamine tetramethylene phosphonate, 40 parts of nitrilotriacetic acid, 20 parts of iminodisuccinic acid, dioctyl sodium sulfosuccinate 35 parts, 35 parts of sodium hydroxide, 35 parts of tetrasodium EDTA, 20 parts of isooctyl alcohol polyoxyethylene ether, 30 parts of cocamidopropyl betaine, 60 parts of coconut acid diethanolamide, 70 parts of polyvinylpyrrolidone, 20 parts of benzotriazole and 20 parts of sodium lignosulfonate) are poured into the reaction kettle, and after pouring, the stirring equipment is started to mix and stir the materials...

Embodiment 3

[0045] Step 1: Preparation of equipment and related materials: use the cleaning device to fully clean the equipment participating in the reaction, then power on the equipment and start it, enter the working standby state, conduct a comprehensive inspection of the degreasing agent participating in the reaction, and eliminate unqualified products;

[0046] Step 2: Basic mixing of materials: mix all major ingredients (30 parts of sodium ethylenediamine tetramethylene phosphonate, 50 parts of nitrilotriacetic acid, 30 parts of iminodisuccinic acid, dioctyl sodium sulfosuccinate 50 parts, 50 parts of sodium hydroxide, 60 parts of tetrasodium EDTA, 30 parts of isooctyl alcohol polyoxyethylene ether, 35 parts of cocamidopropyl betaine, 80 parts of coconut acid diethanolamide, 80 parts of polyvinylpyrrolidone, 25 parts of benzotriazole and 30 parts of sodium lignosulfonate) are poured into the reaction kettle, after pouring, the stirring equipment is started to mix and stir the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com