A method for optimizing the carrier concentration of thermoelectric materials

A technology of carrier concentration and thermoelectric materials, applied in chemical instruments and methods, manufacturing/processing of thermoelectric devices, polycrystalline material growth, etc., can solve problems such as low efficiency, limited optimization process, slow material development process, etc., to achieve The effect of shortening the development cycle and reducing the development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

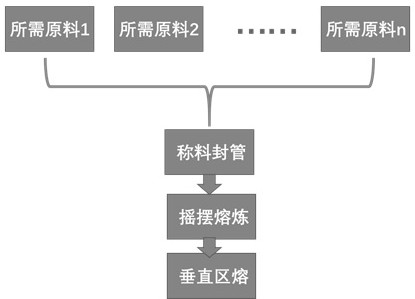

Method used

Image

Examples

Embodiment 1

[0045] (1) N-type bismuth telluride base melting ingot prepared by single melting zone and single zone melting;

[0046] (1.1) Pulverize the raw materials Bi, Te, Se and I;

[0047] (1.2) One end of a quartz tube with an inner diameter of 28mm and a length of about 900mm is sealed with a hydrogen-oxygen flame, and it is flat-bottomed. Wash once with ethanol, then put the quartz tube into an oven and dry at 120°C for 12 hours for later use;

[0048] According to the chemical formula of N-type conventional column Bi 2 Te 2.7 Se 0.3 The stoichiometric ratio of each element in the method weighs 1000g of raw materials in step (1), puts them into a dried quartz tube, and mixes 10g of I element.

[0049] (1.3) the vacuum degree of quartz tube in step (2) is pumped to 10 -3 Pa, and seal the other end of the quartz tube with an oxyhydrogen flame to form a flat bottom;

[0050] (1.4) Place the quartz tube in step (3) in a rotary smelting furnace at 800°C for 10 hours, and keep sha...

Embodiment 2

[0056] (1) P-type bismuth telluride base melting ingot prepared by single melting zone and single zone melting;

[0057] (1.1) Pulverize raw materials Bi, Sb, Te and Fe particles;

[0058] (1.2) One end of a quartz tube with an inner diameter of 28mm and a length of about 900mm is sealed with a hydrogen-oxygen flame, and it is flat-bottomed. Wash once with ethanol, then put the quartz tube into an oven and dry at 120°C for 12 hours for later use;

[0059] According to the P-type chemical formula Bi 1.3 Sb 0.7 Te 3 The stoichiometric ratio of each element in the step (1) takes a total of 1000g of raw materials, puts them into a dried quartz tube, and mixes 10g of Fe element.

[0060] (1.3) the vacuum degree of quartz tube in step (2) is pumped to 10 -3 Pa, and seal the other end of the quartz tube with an oxyhydrogen flame to form a flat bottom;

[0061] (1.4) Place the quartz tube in step (3) in a rotary smelting furnace at 800°C for 10 hours, and keep shaking during the...

Embodiment 3

[0067] (1) N-type bismuth telluride-based ingots prepared by single melting zone and secondary zone melting;

[0068] (1.1) Pulverize the raw materials Bi, Te, Se and Cu;

[0069] (1.2) One end of a quartz tube with an inner diameter of 28mm and a length of about 900mm is sealed with a hydrogen-oxygen flame, and it is flat-bottomed. Wash once with ethanol, then put the quartz tube into an oven and dry at 120°C for 12 hours for later use;

[0070] According to the chemical formula of N-type conventional column Bi 2 Te 2.3 Se 0.7 The stoichiometric ratio of each element in the step (1) was weighed to take a total of 1000g of raw materials, put it into a dried quartz tube, and add 10g of Cu element.

[0071] (1.3) the vacuum degree of quartz tube in step (2) is pumped to 10 -3 Pa, and seal the other end of the quartz tube with an oxyhydrogen flame to form a flat bottom;

[0072] (1.4) Place the quartz tube in step (3) in a rotary smelting furnace at 800°C for 10 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com