Large plate shearing machine hydraulic system

A technology of hydraulic system and shearing machine, applied in the direction of fluid pressure actuating system components, shearing devices, mechanical equipment, etc., can solve the problems of decreasing shearing efficiency, speeding up the return speed, long empty stroke, etc., to reduce the oil circuit The effect of whistling, guaranteeing the downlink speed, and speeding up the return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

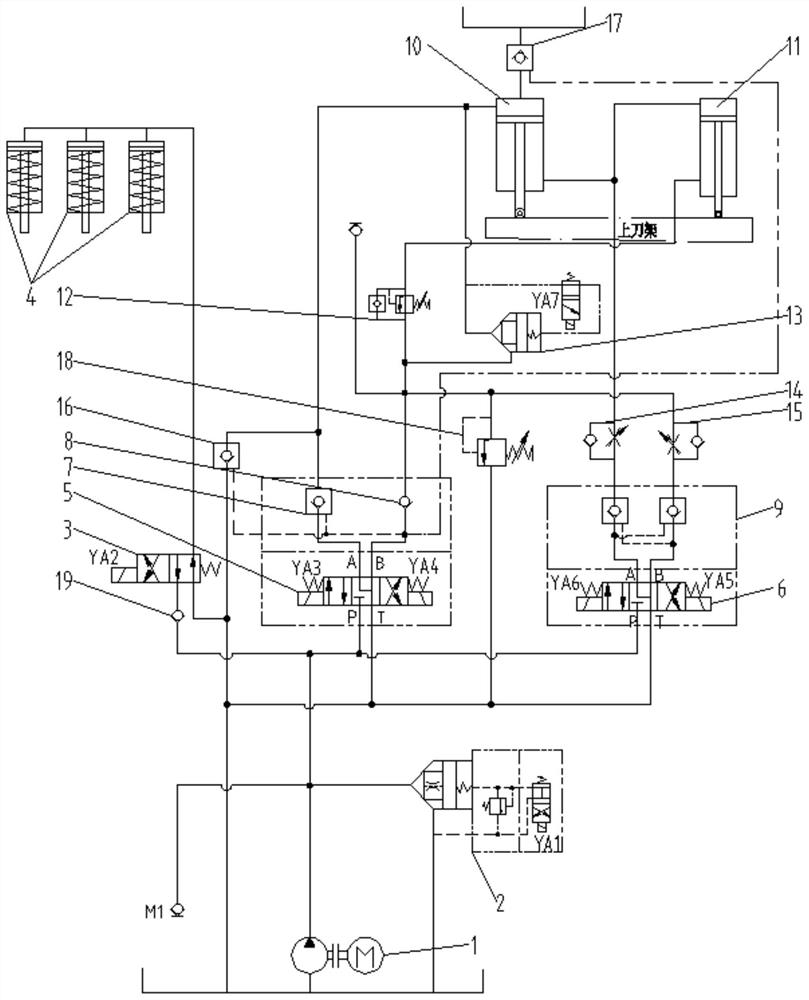

[0045]The upper tool rests fast downward shearing action: solenoid valve four YA4, solenoid valve five YA5, solenoid valve six YA6, solenoid valve seven YA7 are all de-energized, solenoid valve one YA1, solenoid valve two YA2 is first powered, and hydraulic pump 1 is used. The hydraulic oil first enters the rodless cavity of the material pressing cylinder 4 through the one-way valve 19 and the two-position four-way reversing valve 3, so that the material pressing cylinder 4 first presses the workpiece to be cut.

[0046]After 0.5S, solenoid valve three YA3 is energized, and the left position of three-position four-way reversing valve 5 is connected. At this time, P port on three-position four-way reversing valve 5 is connected to port A, and port B is connected to T The hydraulic oil from the hydraulic pump 1 enters the rodless cavity of the main cylinder 10 through the three-position four-way reversing valve 5 and the hydraulic control check valve 7 to push the piston rod of the main ...

Embodiment 2

[0052]The upper tool rest moves upward and backward: solenoid valve two YA2, solenoid valve three YA3, solenoid valve five YA5, solenoid valve six YA6 are all de-energized, solenoid valve one YA1, solenoid valve four YA4, solenoid valve seven YA7 are energized, three positions four The right position of the one-way reversing valve 5 is turned on. At this time, the hydraulic oil in the rodless cavity of the pressure-feeding cylinder 4 returns to the tank through the two-position four-way reversing valve 3 under the action of the spring in the pressure-feeding cylinder 4; The P port on the four-way reversing valve 5 is connected to the B port, and the A port is connected to the T port. The hydraulic oil from the hydraulic pump 1 passes through the three-position four-way reversing valve 5, the one-way valve 8 and the one-way sequence The valve 12 enters the rod cavity of the auxiliary cylinder 11, pushing the piston rod of the auxiliary cylinder 11 upward, and the hydraulic oil in the...

Embodiment 3

[0057]The shear angle of the upper tool post increases: solenoid valve two YA2, solenoid valve three YA3, solenoid valve four YA4, solenoid valve six YA6 are all de-energized, solenoid valve one YA1, solenoid valve five YA5, solenoid valve seven YA7 are energized, three The right position of the two-position four-way reversing valve 6 is connected. At this time, the P port and the B port of the three-position four-way reversing valve 6 are connected, and the A port is connected to the T port. The combined valve 13 is in the closed state, and the main The rodless cavity of the oil cylinder 10 is closed. The hydraulic oil discharged by the hydraulic pump 1 passes through the three-position four-way reversing valve 6 and the hydraulic control check valve on the right side of the two-way hydraulic lock 9, the one-way throttle valve 15 and the one-way The one-way valve in the sequence valve 12 enters the rod cavity of the auxiliary cylinder 11 and pushes the piston rod of the auxiliary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com