Method for evaluating grain boundary diffusion depth of neodymium-iron-boron magnet

A grain boundary diffusion, NdFeB technology is applied in the field of rare earth permanent magnet material detection, which can solve the problems of long process and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Choose A batch of NdFeB magnets, the diffusion source is terbium fluoride, the size of the orientation plane is 80*40mm, and the size of the magnetic field direction is 6mm.

[0022] (2) Take 8 pieces of this batch of NdFeB magnets and carry out wire cutting parallel to the direction of the magnetic field, and process them into samples with an orientation surface size of 20mm*20mm, and pass the processed NdFeB magnets through a precision grinder for orientation Grinding treatment on the surface to prepare a set of NdFeB magnet samples that have been ground to a certain thickness, the grinding thicknesses are 0.8mm, 0.9mm, 1mm, 1.1mm, 1.2mm, 1.3mm, 1.4mm, 1.5mm;

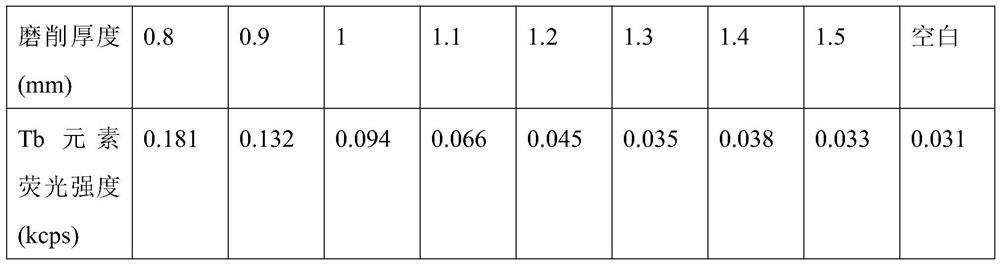

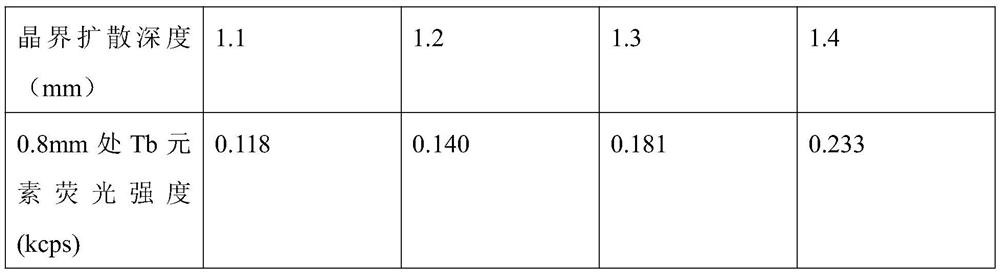

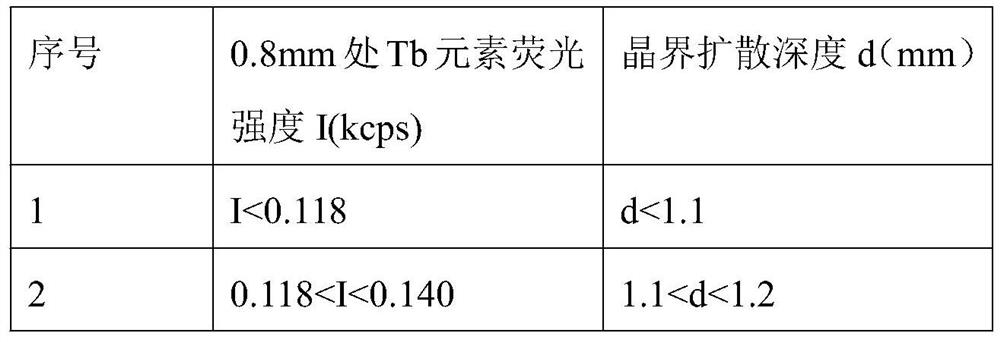

[0023] (3) Measure the NdFeB magnet sample prepared in step (2) by X-ray fluorescence spectrometer, measure the intensity of its Tb element, select this batch of NdFeB magnet sample that has not been processed through grain boundary diffusion process as blank simultaneously, measure Its Tb intensity, the sp...

Embodiment 2

[0036] (1) Select A batch of NdFeB magnets, whose diffusion source is terbium metal, and the magnetic field direction size is 10mm.

[0037] (2) Take 8 pieces of this batch of NdFeB magnets and carry out wire cutting parallel to the direction of the magnetic field, and process them into samples with an orientation surface size of 20mm*20mm, and pass the processed NdFeB magnets through a precision grinder for orientation Grinding treatment on the surface to prepare a set of NdFeB magnet samples that have been ground to a certain thickness. ;

[0038] (3) Measure the NdFeB magnet sample prepared in step (2) by X-ray fluorescence spectrometer, measure the intensity of its Tb element, select this batch of NdFeB magnet sample that has not been processed through grain boundary diffusion process as blank simultaneously, measure Its Tb intensity, the specific results are shown in Table 4;

[0039] Table 4 Grinding thickness of batch A NdFeB magnets in Example 2 and fluorescence test...

Embodiment 3

[0051](1) Select A batch of NdFeB magnets, the diffusion source is dysprosium hydride, and the magnetic field direction size is 8mm.

[0052] (2) Take 7 pieces of this batch of NdFeB magnets and perform wire cutting parallel to the direction of the magnetic field, and process them into samples with an orientation surface size of 20mm*20mm, and pass the processed NdFeB magnets through a precision grinder for orientation Grinding treatment on the surface to prepare a set of NdFeB magnet samples that have been ground to a certain thickness, and the grinding thicknesses are 0.8mm, 1.1mm, 1.2mm, 1.3mm, 1.4mm, 1.5mm, 1.6mm;

[0053] (3) Measure the NdFeB magnet sample prepared in step (2) by X-ray fluorescence spectrometer, measure the intensity of its Dy element, select this batch of NdFeB magnet sample that has not been processed through the grain boundary diffusion process as blank simultaneously, measure Its Dy intensity, the specific results are shown in Table 7;

[0054] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com