BIM technology-based accurate positioning construction method for reserved hole channel in continuous beam construction

A construction method and precise positioning technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems affecting the appearance quality of continuous beam concrete, increasing cost and resource investment, and much interference between tunnels and corrugated pipes, etc., to achieve Reduce construction risk, reduce unnecessary rework, and reduce the effect of high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

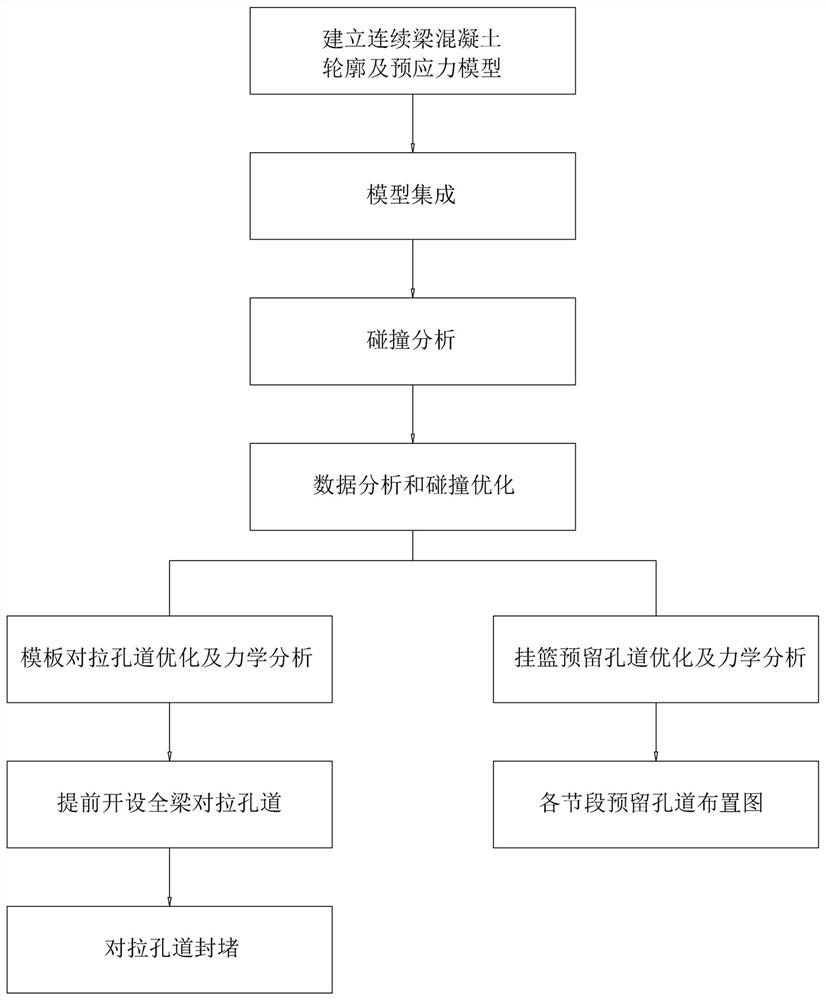

[0030]The following is attachedfigure 1Give further details on this application.

[0031]The embodiment of the present application discloses a construction method for precise positioning of reserved holes for continuous beam construction based on BIM technology. A construction method for precise positioning of reserved holes for continuous beam construction based on BIM technology, including the following steps:

[0032]S1. Model establishment: According to the structure and design drawings after inspection, apply BIM technology to carry out 1:1 proportional modeling of the continuous beam concrete profile and prestress system model, determine the model size information, and control the model accuracy error at the millimeter level;

[0033]The continuous beam concrete contour model establishment method is selected according to the line type of the bottom edge of the continuous beam body bottom plate. The model establishment sequence is: coordinate positioning, create contour family, create c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com